(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla Firefox.

50,000 Stock items for Same Day Ship Out.

All Categories

Categories

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Application

Brands

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Slit Couplings Long, Clamping Type (Part Numbers)

- On Sale Till 31/03/2025

- Volume Discount

Are economically priced with the quality/perforce kept to the same level as conventional products. Can serve as the substitute for CPLC Type.

Part Number

Configured Part Number is shown.

coupling Product Overview

The parallel line coupling usually has 3 to 5 slots to deal with the problem of low torque rigidity.

The parallel line coupling takes into account the shortening of slots without weakening the ability to bear and correct deviation. Short slots can enhance and overlap the torque rigidity of the coupling, so that it can bear considerable torque.

coupling Product Feature

【Usage】Suitable for standard motors

【Precautions】Moment of inertia and weight are calculated at the maximum shaft dia.

【Type】Grooved type

【Body Material】Aluminum alloy

【Fixing System】Clamping screw fixing type

【Applicable Motors】Servo motors and stepping motors

■ Parallel line couplings are suitable for light load applications.

Dimensional coupling Drawing

Material Material |  Surface Treatment Surface Treatment |  Accessories Accessories |

| Aluminum | Alumite Treatment | Fastening Bolt |

coupling Specification Table

| D | d1 | d2 | L | ℓ | F | A | Fastening Bolt | ||||||||

| M (Coarse Thread) | Tightening torque (N·m) | ||||||||||||||

| 16 | 4 | 4 | 5 | 23 | 6.4 | 3.2 | 5.5 | M2.5 | 1.0 | ||||||

| 5 | 5 | 8 | |||||||||||||

| 20 | 5 | 6 | 8 | 26 | 7 | 3.5 | 6.5 | ||||||||

| 6 | 6 | 8 | 10 | ||||||||||||

| 25 | 6 | 10 | 31 | 8 | 4 | 8.5 | M3 | 1.5 | |||||||

| 6.35 | 8 | 10 | |||||||||||||

| 8 | 8 | 10 | 12 | ||||||||||||

| 32 | 10 | 10 | 11 | 12 | 14 | 41 | 11 | 5.5 | 10.5 | M4 | 3.5 | ||||

| 12 | 12 | 14 | |||||||||||||

■Characteristic Value

| D | Allowable torque (N·m) | Maximum rotational speed (rpm) | Moment of inertia (kg·m2) | Static torsional stiffness (N·m/rad) | Allowable lateral misalignment (mm) | Allowable Angular Misalignment ( ° ) | Allowable axial amplitude (mm) | Weight (g) |

| 16 | 0.5 | 10,000 | 7.0×10-7 | 53 | 0.1 | 2 | ±0.4 | 9 |

| 20 | 1 | 1.6×10-6 | 120 | 16 | ||||

| 25 | 2 | 4.4×10-6 | 260 | 0.15 | ±0.5 | 28 | ||

| 32 | 4 | 1.7×10-5 | 550 | 66 |

Static torsional stiffness, moment of inertia and weight are the values at the maximum shaft dia..

Static torsional stiffness, moment of inertia and weight are the values at the maximum shaft dia..coupling Precautions

1. The coupling allows axis deviation, and transmits rotation angle and torque, but when the axis deviation exceeds the allowable value, vibration will occur or the service life will be drastically reduced.

Be sure to make calibration and adjustment.

2. Axis deviation includes lateral misalignment (parallel error of two axes), angular misalignment (angular error of two axes) and axial amplitude (axial movement of shaft).

Please calibrate and adjust the shaft to ensure that the axis deviation is below the allowable value recorded in the dimension and performance table of each product.

3. The allowable value of axis deviation recorded in the dimension and performance table refers to the situation when either lateral misalignment, angular misalignment or axial amplitude occurs alone. When more than two axis deviations occur at the same time, the corresponding allowable values are halved respectively.

4. Axis deviation not only occurs when assembling to the device, but also is caused by vibration, thermal expansion and bearing wear in operation. Therefore, it is recommended to set the axis deviation below 1/3 of the allowable value.

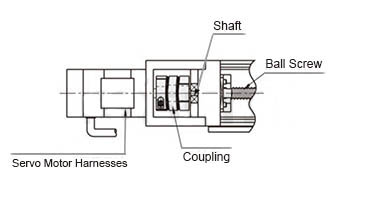

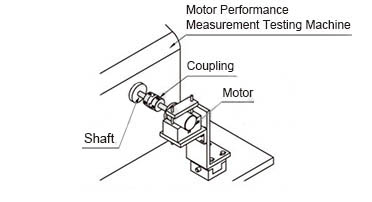

Example of Use coupling

coupling Usage Method

STEP1 Insert the coupling

Confirm that the clamping bolt has been unscrewed, and then remove the dust, foreign matter and oil from the shaft and coupling bore.

Then, when inserting the coupling into the shaft, please be careful not to put the disc under excessive stress such as compression or tension.

STEP2 Use fixture to adjust

Please use fixture to adjust and fix the concentricity of the left and right hubs of the coupling with high accuracy.

STEP3 Simple lateral misalignment and angular misalignment confirmation

Under the condition of unscrewed bolts, make the coupling slide axially and confirm its smooth movement.

Then, rotate the coupling to make sure it moves smoothly.

Lateral misalignment is not allowed for single disc type coupling, so carry out positioning securely.

STEP4 Installation

Please adjust the shaft insertion amount according to the dimension ℓ in the product catalog, and use a torque wrench to tighten with the specified torque.

* If the specified torque cannot be reached once, please cross fasten the left and right clamps twice or three times.

Part Number

CAD Data download and 3D preview are not available because the part number has not yet been determined.

- *In order to open the CAD Data download and 3D preview screen, the part number must be fixed.

- Please confirm the part number from "Specification / Dimension"on the left side, and then perform the CAD Data Download / 3D Preview operation.

| Part Number |

|---|

| GSACL32-10-10 |

| GSACL32-10-11 |

| GSACL32-10-12 |

| GSACL32-10-14 |

| GSACL32-12-12 |

| GSACL32-12-14 |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to Ship | RoHS | Shaft Bore Dia. 1 d1 (or d) (Ø) | Shaft Bore Dia. 2 d2 (or d) (Ø) | O.D. (Ø) | Overall Length (mm) | Allowable Torque Range (N•m) | Allowable Torque (N•m) | Allowable Lateral Misalignment (mm) | Allowable Axial Misalignment (mm) | Moment of Inertia (kg・m2) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

SGD 28.89 | 1 Piece(s) | Available | Same day | 10 | 10 | 10 | 32 | 41 | 3.01~5.00 | 4 | 0.15 | 0.5 | 1.7×10-5 | |

SGD 28.89 | 1 Piece(s) | Available | Same day | 10 | 10 | 11 | 32 | 41 | 3.01~5.00 | 4 | 0.15 | 0.5 | 1.7×10-5 | |

SGD 28.89 | 1 Piece(s) | Available | Same day | 10 | 10 | 12 | 32 | 41 | 3.01~5.00 | 4 | 0.15 | 0.5 | 1.7×10-5 | |

SGD 28.89 | 1 Piece(s) | Available | Same day | 10 | 10 | 14 | 32 | 41 | 3.01~5.00 | 4 | 0.15 | 0.5 | 1.7×10-5 | |

SGD 28.89 | 1 Piece(s) | Available | Same day | 10 | 12 | 12 | 32 | 41 | 3.01~5.00 | 4 | 0.15 | 0.5 | 1.7×10-5 | |

SGD 28.87 | 1 Piece(s) | Available | Same day | 10 | 12 | 14 | 32 | 41 | 3.01~5.00 | 4 | 0.15 | 0.5 | 1.7×10-5 |

Loading...

Days to Ship

Overview · Features

Basic Information

| Series Name | Slit | Application | For Servo Motors / Stepping Motor | Features | High Torsional Rigidity / Zero Backlash / Low Moment of Inertia |

|---|---|---|---|---|---|

| Allowable Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | Max. Rotational Speed Range(r/min) | 4001~10000 | Body Material | Aluminum Alloy |

| Allowable Angular Misalignment(deg) | 2 | Product Category | Coupling Main Body | Allowable Lateral Misalignment Range(mm) | 0.02~0.2 |

| Max. Rotational Speed(r/min) | 10000 | Standard/Short | Standard Type | Shaft Bore Shape | Standard Bore |

| Shaft Tightening Method | Fastening Bolt |

Specification/Dimensions

-

Shaft Bore Dia. 1 d1 (or d)(Ø)

-

Shaft Bore Dia. 2 d2 (or d)(Ø)

-

O.D.(Ø)

-

Overall Length(mm)

-

Allowable Torque(N•m)

-

Allowable Lateral Misalignment(mm)

-

type

- GSACL

-

Allowable Torque Range(N•m)

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- Same day

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: What is a coupling?

- Answer: A coupling is a part that connects two different rotating bodies (motor shaft, ball screw, etc.) and aims at transmitting torque. The load of assembly adjustment is reduced by absorbing the axis deviation (lateral misalignment, angular misalignment and axial amplitude) between rotating bodies. And in case of accidental overload, the coupling is destroyed and the rotating bodies are disconnected to protect the expensive power part and the whole device.

- Question: What are the types of MISUMI couplings?

- Answer: There are disc type, grooved type, cross type, claw type, bellows type, rigid type and universal joint type.

- Question: How to select coupling according to motor?

- Answer: Disc type is recommended for servo motors, grooved type is recommended for stepping motors, and cross type is recommended for universal motors.

- Question: How to select according to the purpose, environment, working conditions?

- Answer: Please refer to the MISUMI website.

- Question: What kind of coupling should be used when the angular misalignment is very large?

- Answer: Please select the universal joint with allowable angular misalignment of 30 degrees. In addition, when grease cannot be applied regularly, use a rubber sleeve to fill grease and use it.

- Question: Which disc type coupling is better, single disc type or double disc type?

-

Answer:

Double disc type can absorb angular misalignment and lateral misalignment, but the total length will increase.

Although the total length of the single disc type is short, it is only suitable for applications with narrow space because lateral misalignment is not allowed in the structure. Special attention should be paid to centering during use. - Question: How much is appropriate to insert the shaft into the coupling during installation?

- Answer: Please select the length of the main body (coupling part) described in the product catalog. If the insertion amount is too short, the shaft may slip and the clamping part may be damaged; If the insertion amount is too long, it will be damaged due to shaft interference inside the coupling.

- Question: Why is it necessary to install a protection cover around the coupling?

- Answer: Due to high-speed rotation, accidental contact may result in injury or entanglement of gloves, towels, etc. In addition, for some reasons, parts may be damaged or debris may be scattered. Therefore, be sure to install the safety protection cover.

- Question: What should I do if there is no matching shaft bore diameter?

- Answer: Please select a product with changeable keyway width or available with keyway processing. MISUMI products are divided into MCSLCWK series (disc type), CPOC series (cross type) and MMJN series (claw type), etc.

- Question: Is it a defective product that has difference in groove gap width?

- Answer: Since the difference is within the dimensional tolerance range, there is no problem.

Tech Support

- Factory Automation, Electronics, Tools, & MRO (Maintenance, Repair and Operations)

- Tel:(65) 6733 7211 / FAX:(65) 6733 0211

- 9:00am - 6:00pm (Monday - Friday)

- Technical Inquiry

How can we improve?

How can we improve?