(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla Firefox.

50,000 Stock items for Same Day Ship Out.

All Categories

Categories

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Application

Brands

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

- Please be informed that there will be no shipment from Japan during the upcoming year-end and New Year holiday period. However, Singapore’s stock items are available during these periods. Click here for details.

PMS-LB Model Swivel Wheel Lever Type (With Double Stopper) (PMS-150GUBLB(R))

A caster recommended for towing with excellent life span, traveling performance and operability

Japanese Only

Part Number

Configured Part Number is shown.

PMS-150GUBLB(R)

- Yuei Caster PM series

Long life with improved durability. Running cost greatly decreased.

- Fully prevents resonance during towing. Decreased load on the turning portion, dramatically reducing tread abrasion.

- Adopted new material (high tensile steel) to further improve durability. Long life reduces cost.

Features Of PM Series

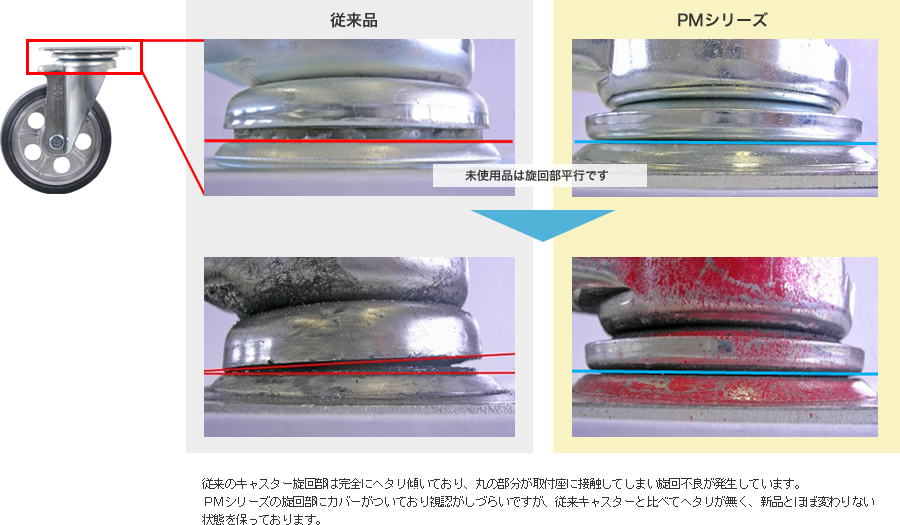

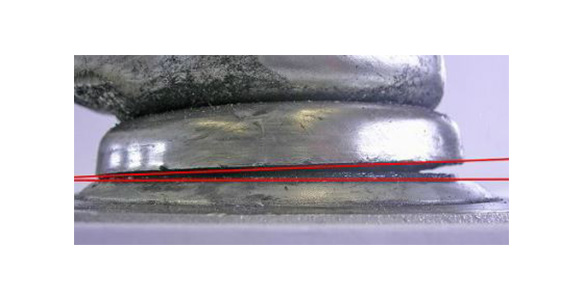

Comparison Photos Of Products Actually Used At Factory Facilities For 1 Year (Turning Portion)

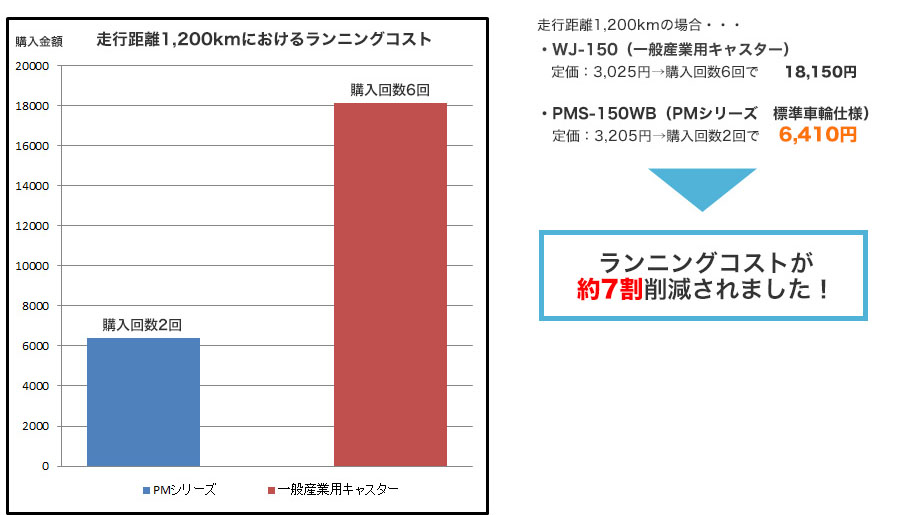

Running Cost Comparison

Running cost difference for 1,200 km travel distance for one cart (4 casters).

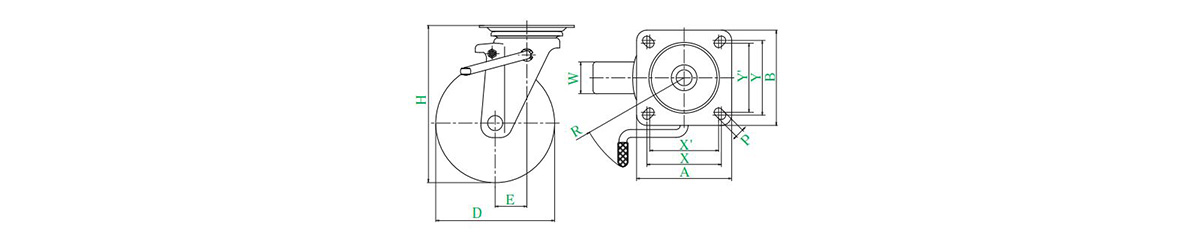

PMS-LB Model Swivel Wheel Plate Type Lever Type (With Double Stopper) Caster Outline Drawing And Dimensions

PMS-LB model swivel wheel plate type lever type (with double stopper) caster outline drawing

| Part Number | Wheel | Wheel Diameter | Wheel Width | Mounting Height H | Mounting Seat | Mounting Dimension | Hole Diameter | Eccentricity | Turning Radius | Allowable Load | Dead Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D (mm) | W (mm) | H (mm) | A × B (mm) | X × Y (X' × Y') (mm) | P (mm) | E (mm) | R (mm) | daN (kgf) | (g) | ||||

| PMS-130 | WB | LB (R) | Steel plate wheels, rubber (B included) tread | 130 | 40 | 177 | 110 × 110 | 90 × 90 (80 × 80) | 11 | 40 | 138 | 180 (183.6) | 1,870 |

| UWB | Steel plate wheels urethane (B included) tread | 35 | 250 (255.0) | 2,250 | |||||||||

| GUB | Nylon wheel urethane tread (B included) | 40 | 180 (183.6) | ||||||||||

| PMS-150 | WB | LB (R) | Steel plate wheels, rubber (B included) tread | 150 | 40 | 198 | 120 × 120 | 94 × 94 (87 × 87) | 11 | 40 | 138 | 200 (204.0) | 2,110 |

| AW | Aluminum wheel rubber (B included) tread | 42 | 250 (255.0) | 2,230 | |||||||||

| UWB | Steel plate wheels urethane (B included) tread | 38 | 300 (306.0) | 2,580 | |||||||||

| GUB | Nylon wheel urethane tread (B included) | 40 | 200 (204.0) | ||||||||||

| PMS-200 | WB | LB (R) | Steel plate wheels, rubber (B included) tread | 200 | 43 | 250 | 144 × 144 | 120 × 120 (105 × 105) | 11.5 | 56 | 156 | 250 (255.0) | 4,025 |

| AW | Aluminum wheel rubber (B included) tread | 45 | 300 (306.0) | 4,050 | |||||||||

| UWB | Steel plate wheels urethane (B included) tread | 42 | 400 (408.0) | 4,105 | |||||||||

| GUB | Nylon wheel urethane tread (B included) | 43 | 250 (255.0) | ||||||||||

Fixtures: trivalent bright chromate finishing

Includes a double stopper which can lock the installation portion swivel and lock the wheel rotation.

AW wheels (aluminum wheel rubber (B included) tread) are suited for towing.

Superior Series Performance, Outdoing Conventional Products

New Structure With Precision Pathways For Steel Balls Serving As Bearings

Drawing of new structure turning portion

Durability further improved by changing the turning portion structure to eliminate unsteadiness. Therefore the superior operability continues just like new.

Attained Over 5 Times The Life Of A Conventional Product

Used for tow carts. Abraded in less than 1 year, requiring replacement.

Used for tow carts. Used over 1 year without replacing.

- *The image shows casters colored red when used.

Light And Easy Operability With Turning Load Reduced By About 40%

- The M series reduced our running costs.

- Used on towing cart

- We had used the conventional product, but since we started using the PM series the number of caster replacements dropped significantly.

- Used on push cart

- The PM series has no problem with durability, even when towed.

- Used on towing cart

Development Secrets

Reason For Development

The PM series are high performance industrial use casters that are strong, turn easily, have light deadweight, and have reduced noise. This was developed with the concept of targeting a higher end compatible product with the conventionally sold J series, which are general industrial use casters. This also suppresses increases in costs.

Firstly, the reasons leading to development of a higher-end compatible product for industrial use casters are as follows. Industrial use casters used for factory carts, etc., are consumable goods. There is an aspect of emphasizing cost over performance, and the J series sufficiently met a specific performance standard.

But this series only met that specific standard, and had much room for improvement when considering the needs of the customers using the product with regards to durability, operability, noise, etc. Conventional products on the market include many casters with the described performance level, but these were not very cost-efficient. Then we wondered whether we could make industrial use casters that maintain the same cost and provide the kind of performance that will satisfy customers, and set out to develop the PM series.

Challenges Along The Way And Encountering New Materials

We started PM series development with solid goals, but development was hardly smooth, and we did encounter problems. As you would expect from what you have read above, the performance and costs were difficult to balance. We went through many shape concepts and recalculations.

We arrived at using high-strength material, like an automobile body that uses high tensile steel. Using this material enables attaining higher strength than the conventional product, even though the plate thickness is thinner than the conventional product. This allowed us to balance the cost and lighten the dead weight. We are very satisfied with finding an ideal material. But the press processing method differed from the conventional product when the new material was adopted, and we had some difficulty with processing it to the dimensional accuracy required for functioning as a caster. We thoroughly evaluated every possible factor and went through a trial-and-error process.

Discovery Of New Added Value

By repeating the trial-and-error process, not only did we attain the performance initially intended, but we also additionally succeeded at reducing resonance occurrence. Resonance refers to caster vibrations that occur during high speed travel. Resonance occurrence applies excess load to the casters and leads to early damage. The combination of preventing resonance and the aforementioned more durable new material resulted in the creation of a caster with long service life. Additionally, resonance occurrence leads to noise. By preventing resonance from occurring, noise was also reduced. We succeeded at reducing resonance occurrence by developing a new structure for the turning portion, with a proprietary pathway for steel balls serving as bearings. This was made with precision, eliminating the unsteadiness of conventional products and enabling maintaining like new superior operability for a long time.

The PM Series Casters

In addition to meeting the initially mentioned product concept of being strong, turning easily, having light dead weight, and having reduced noise, the PM series also became casters with very long service life. Long service life means proportionately decreased costs of repurchasing and replacing, which in turn reduces the running cost for customers. We were very pleased with this, because development of the PM series started with wanting to leave the costs the same while creating industrial use casters with performance that satisfies our customers. Our customers will be happier with reduced costs compared to costs remaining the same.

Praise From Our Customers

Though this differs by the customer usage environment, we have received comments from happy customers saying that the service life nearly tripled. Customers using this for towing are also giving us good reports. We urge you to give these a try.

Product Variations

PMS model swivel wheel plate type

PMS model swivel wheel plate type

PMR model fixed wheel plate type

PMR model fixed wheel plate type Features: with fixed wheel

| Part Number |

|---|

| PMS-150GUBLB(R) |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to Ship | Mounting Height H (mm) | Load Range (daN) | Allowable Load (daN) | Wheel Material | Wheel Characteristics | Mounting Hole Pitch, Long Length Direction L1 (mm) | Mounting Hole Pitch, Short Length Direction W1 (mm) | Plate Length (mm) | Plate Width (mm) | Wheel Dia. D (Ø) | Wheel Width (mm) | Swivel Radius (mm) | Load Category | Combination of Slotted Hole Pitch | Stopper | Wheel Bearings | Stopper Lever Type | Foil material |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

SGD 54.90 | 1 Piece(s) | 6 Day(s) or more | 198 | 140.01~220.00 | - | [Urethane] Aluminum Foil Thermosetting Urethane Foam | Abrasion Resistance / Gasoline Resistance (Light Oil included) / Oil Resistance | 87 (94) | 87 (94) | - | - | - | - | 138 | Heavy Load | - | Yes | Yes | Lever type double stoppers attached (right) | Nylon |

Loading...

Basic Information

| Caster Type | Plate Type Universal | Stopper (Detail) | With Double Stopper (Rotation + Turning) | Fitting Material | Steel |

|---|---|---|---|---|---|

| Mounting Hole Type | Slotted Holes | Application | Factory facilities |

Specification/Dimensions

-

Allowable Load(daN)

-

Wheel Characteristics

- Abrasion Resistance

- Gasoline Resistance (Light Oil included)

- Oil Resistance

- No

-

Plate Length(mm)

-

Plate Width(mm)

-

Wheel Dia. D(Ø)

-

Wheel Width(mm)

-

Combination of Slotted Hole Pitch

- 90-90, 80-80

- 94-94, 87-87

- 120-120, 105-105

-

type

- PMS-GUBLB(R)

- PMS-LB

-

Mounting Height H(mm)

-

Load Range(daN)

- 140.01~220.00

- 220.01~320.00

- 320.01~485.00

-

Wheel Material

- Rubber

- Urethane

-

Mounting Hole Pitch, Long Length Direction L1(mm)

-

Mounting Hole Pitch, Short Length Direction W1(mm)

-

Swivel Radius(mm)

-

Stopper

- Presence

- Yes

-

Wheel Bearings

- Presence

- Yes

-

Stopper Lever Type

-

Foil material

- Aluminum

- Nylon

- Steel plate

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- 4 Day(s) or Less

- 6 Day(s) or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: Which of the applicable wheels is designed for traction?

- Answer: The aluminum foil rubber wheels (AW).

- Question: How long is the "long life" indicated?

- Answer: While conventional products involved 6 replacements over 1200 km of travel distance, the PM series requires just 2 replacements. By reducing the number of replacements, running costs can be significantly decreased.

Tech Support

- Factory Automation, Electronics, Tools, & MRO (Maintenance, Repair and Operations)

- Tel:(65) 6733 7211 / FAX:(65) 6733 0211

- 9:00am - 6:00pm (Monday - Friday)

- Technical Inquiry

How can we improve?

How can we improve?