(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla Firefox.

50,000 Stock items for Same Day Ship Out.

All Categories

Categories

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Application

Brands

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Filter Regulator AW20 to 60-B, Filter Regulator With Backflow Function AW20K to 60K-B (AW30-02DE1-B)

- On Sale Till 31/03/2025

Filter regulators and filter regulators with backflow function, with both filter and regulator integrated in one unit.

[Features]

· Helps save on space, and requires less piping.

(i)Caution

- Refer to the catalog for details on product specifications.

- The products shown in the image are representative. CAD data is not supported for some model numbers.

Part Number

Configured Part Number is shown.

AW30-02DE1-B

Filter Regulator AW20-B To AW60-B And Filter Regulator With Backflow Function AW20K-B To AW60K-B Details

AW20-B/AW20K-B: product images

AW40-B/AW40K-B: product images

Filter Regulator AW20-B To AW60-B And Filter Regulator With Backflow Function AW20K-B To AW60K-B Specifications

| Model | AW20-B | AW30-B | AW40-B | AW40-06-B | AW60-B |

|---|---|---|---|---|---|

| Piping connection port diameter | 1/8, 1/4 | 1/4, 3/8 | 1/4, 3/8, 1/2 | 3/4 | 3/4, 1 |

| Pressure gauge connection port size Note 1) | 1/8 | ||||

| Applicable fluids | Air | ||||

| Ambient temperature and working fluid temperature Note 2) | -5 to 60°C (no freezing) | ||||

| Proof pressure | 1.5 MPa | ||||

| Maximum operating pressure | 1.0 MPa | ||||

| Set pressure range | 0.05 to 0.85 MPa | ||||

| Filtration | 5 mm | ||||

| Drain capacity (cm3) | 8 | 25 | 45 | ||

| Case materials | Polycarbonate | ||||

| Bowl guard | Semi-standard (steel) | Standard equipment (polycarbonate) | |||

| Structure | Relieving type | ||||

| Weight (kg) | 0.20 | 0.36 | 0.66 | 0.72 | 2.05 |

Note 1) For the specification with the square embedded type pressure gauge and the specification with the digital pressure switch, there are no pressure gauge connection screws.

Note 2) With a digital pressure switch: −5 to 50°C.

Options / Part No.

| Option specification | PNP output / Wiring top entry | ||||||

|---|---|---|---|---|---|---|---|

| AW20(K)-B | AW30(K)-B | AW40(K)-B | AW40(K)-06-B | AW60(K)-B | |||

| Bracket assembly Note 1) | AW23P-270AS | AR33P-270AS | AR43P-270AS | AW62P-270AS | |||

| Set nut | AR23P-260S | AR33P-260S | AR43P-260S | -Note 2) | |||

| Pressure gauge | Round-type Note 3) | Standard | G36-10-□01 | G46-10-□01 | |||

| 0.02 to 0.2‑MPa setting | G36-4-□01 | G46-4-□01 | |||||

| Round-type Note 3) (with color zone) | Standard | G36-10-□01-L | G46-10-□01-L | ||||

| 0.02 to 0.2‑MPa setting | G36-4-□01-L | G46-4-□01-L | |||||

| Square Note 4) embedded type | Standard | GC3-10AS [GC3P-010AS (pressure gauge cover only)] | |||||

| 0.02 to 0.2‑MPa setting | GC3-4AS [GC3P-010AS (pressure gauge cover only)] | ||||||

| Digital pressure switch Note 5) | NPN output / Wiring bottom entry | ISE35-N-25-MLA [ISE35-N-25-M (main switch unit only)] | |||||

| NPN output / Wiring top entry | ISE35-R-25-MLA [ISE35-R-25-M (main switch unit only)] | ||||||

| PNP output / Wiring bottom entry | ISE35-N-65-MLA [ISE35-N-65-M (main switch unit only)] | ||||||

| PNP output / Wiring top entry | ISE35-R-65-MLA [ISE35-R-65-M (main switch unit only)] | ||||||

Note 1) Assembly of a bracket and set nuts.

The AW60(K)-B has mounting screws (2 pcs.) included.

Note 2) Consult separately with the manufacturer regarding the set nuts for the AW60(K)-B.

Note 3) The □ in the part numbers for round-type pressure gauges indicates the connection thread type.

Insert no symbol for Rc, and use "N" for NPT.

Contact the manufacturer regarding the supply of psi unit specification pressure gauges.

Note 4) Including O-ring (1 pc.) and mounting screws (2 pcs.).

[ ]: Pressure gauge cover only.

Note 5) In addition to the pressure switch, it also includes a lead wire with connector (2 m), adapter, lock pin, O-ring (1 pc.) and mounting screws (2 pcs.).

[ ]: Switch unit only.

If mounting a pressure switch to the AW60(K)-B, a separate special mounting adapter (pressure switch adapter assembly: AW63P-310AS),

and special mounting screws (M3 × 0.5 × 14) (delivered together with the mounting adapter) are required.

Bowl assembly / Part number

| Case materials | Drain discharge mechanism | Drain exhaust port | Other | Model | ||||

|---|---|---|---|---|---|---|---|---|

| AW20-B | AW30-B | AW40-B | AW40-06-B | AW60-B | ||||

| Polycarbo -nate | Manual discharge | With drain cock | - | C2SF-A | - | - | ||

| With bowl guard | C2SF-C-A | C3SF-A | C4SF-A | |||||

| Drain cock, with barb fitting | With bowl guard | - | C3SF-W-A | C4SF-W-A | ||||

| With drain guide (without valve function) | - | C2SF□-J-A | - | - | ||||

| With bowl guard | C2SF□-CJ-A | C3SF□-J-A | C4SF□-J-A | |||||

| Automatic discharge Note) (auto drain) | Normally closed (N.C.) | - | AD27-A | - | - | |||

| With bowl guard | AD27-C-A | AD37□-A | AD47□-A | |||||

| Normally open (N.O.) | With bowl guard | - | AD38□-A | AD48□-A | ||||

| Nylon | Manual discharge | With drain cock | - | C2SF-6-A | - | - | ||

| With bowl guard | C2SF-6C-A | C3SF-6-A | C4SF-6-A | |||||

| Drain cock, with barb fitting | With bowl guard | - | C3SF-6W-A | C4SF-6W-A | ||||

| With drain guide (without valve function) | - | C2SF□-6J-A | - | - | ||||

| With bowl guard | C2SF□-6CJ-A | C3SF□-6J-A | C4SF□-6J-A | |||||

| Automatic discharge Note) (auto drain) | Normally closed (N.C.) | - | AD27-6-A | - | - | |||

| With bowl guard | AD27-6C-A | AD37□-6-A | AD47□-6-A | |||||

| Normally open (N.O.) | With bowl guard | - | AD38□-6-A | AD48□-6-A | ||||

| Metal | Manual discharge | With drain cock | - | C2SF-2-A | C3SF-2-A | C4SF-2-A | ||

| With level gauge | - | C3LF-8-A | C4LF-8-A | |||||

| With drain guide (without valve function) | - | C2SF□-2J-A | C3SF□-2J-A | C4SF□-2J-A | ||||

| With level gauge | - | C3LF□-8J-A | C4LF□-8J-A | |||||

| Automatic discharge Note) (auto drain) | Normally closed (N.C.) | - | AD27-2-A | AD37□-2-A | AD47□-2-A | |||

| With level gauge | - | AD37□-8-A | AD47□-8-A | |||||

| Normally open (N.O.) | - | - | AD38□-2-A | AD48□-2-A | ||||

| With level gauge | - | AD38□-8-A | AD48□-8-A | |||||

Note) Minimum operating pressure - N.O. Type: 0.1 MPa (AD38-A, AD48-A); N.C. Type: 0.1 MPa (AD27-A), and 0.15 MPa (AD37-A, AD47-A).

The bowl assembly comes with a bowl seal. The □ in the bowl assembly part number indicates a tubing thread type (applicable tubing for an auto drain).

No indication is necessary for Rc thread; however, indicate N for NPT thread, and F for G thread. (For auto drain, Nil: ø10 [diameter 10 mm]; N: ø3/8 [diameter 3/8]")

Please consult with manufacturer separately regarding psi and °F unit display specifications.

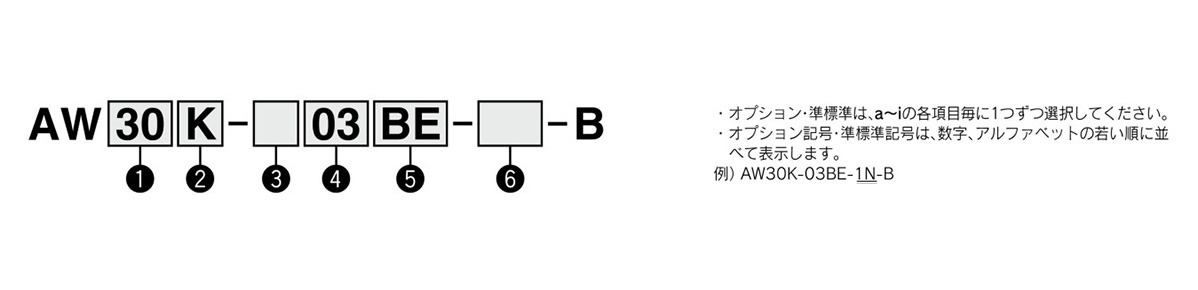

Model Number Notation

Model number example

| - | Code | Contents | (1) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Body size | |||||||||

| 20 | 30 | 40 | 60 | ||||||

| (2) | With backflow function | No symbol | Without backflow function | ● | ● | ● | ● | ||

| K Note 1) | With backflow function | ● | ● | ● | ● | ||||

| (3) | Screw Type | No symbol | Rc | ● | ● | ● | ● | ||

| N Note 2) | NPT | ● | ● | ● | ● | ||||

| F Note 3) | G | ● | ● | ● | ● | ||||

| (4) | Piping connection port diameter | 01 | 1/8 | ● | - | - | - | ||

| 02 | 1/4 | ● | ● | ● | - | ||||

| 03 | 3/8 | - | ● | ● | - | ||||

| 04 | 1/2 | - | - | ● | - | ||||

| 06 | 3/4 | - | - | ● | ● | ||||

| 10 | 1 | - | - | - | ● | ||||

| (5) | Note 4) Option | a | Mounting | No symbol | Without optional mounting parts | ● | ● | ● | ● |

| B Note 5) | With Bracket | ● | ● | ● | ● | ||||

| H | With set nut (for panel mount) | ● | ● | ● | - | ||||

| b | Float type auto drain | No symbol | Without auto drain | ● | ● | ● | ● | ||

| C Note 6) | N.C. (Normally Closed) Drain port is closed when no pressure is applied | ● | ● | ● | ● | ||||

| D Note 7) | N.O. (Normally Open) Drain port is open when no pressure is applied | - | ● | ● | ● | ||||

| c | Pressure gauge Note 8) | No symbol | Without pressure gauge | ● | ● | ● | ● | ||

| E | Square embedded-type pressure gauge (with limit indicator) | ● | ● | ● | ● | ||||

| G | Round-type pressure gauge (with limit indicator) | ● | ● | ● | ● | ||||

| M | Round-type pressure gauge (with color zone) | ● | ● | ● | ● | ||||

| Digital Note 9) Pressure switch | E1 | Output: NPN output / Lead wire electrical entry: wiring bottom entry | ● | ● | ● | ● | |||

| E2 | Output: NPN output / Lead wire electrical entry: wiring top entry | ● | ● | ● | ● | ||||

| E3 | Output: PNP output / Lead wire electrical entry: wiring bottom entry | ● | ● | ● | ● | ||||

| E4 | Output: PNP output / Lead wire electrical entry: wiring top entry | ● | ● | ● | ● | ||||

| (6) | Semi-standard | d | Set pressure Note 10) | No symbol | 0.05 to 0.85‑MPa setting | ● | ● | ● | ● |

| 1 | 0.02 to 0.2‑MPa setting | ● | ● | ● | ● | ||||

| e | Case | No symbol | Polycarbonate bowl | ● | ● | ● | ● | ||

| 2 | Metal bowl | ● | ● | ● | ● | ||||

| 6 | Nylon bowl | ● | ● | ● | ● | ||||

| 8 | Metal bowl with level gauge | - | ● | ● | ● | ||||

| C | With bowl guard | ● | -Note 12) | -Note 12) | -Note 12) | ||||

| 6C | With bowl guard (nylon bowl) | ● | -Note 13) | -Note 13) | -Note 13) | ||||

| f | Drain port Note 14) | No symbol | With drain cock | ● | ● | ● | ● | ||

| J Note 15) | Drain guide 1/8 | ● | - | - | - | ||||

| Drain guide 1/4 | - | ● | ● | ● | |||||

| W Note 16) | Drain cock with barb fitting | - | ● | ● | ● | ||||

| - | Code | Contents | (1) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Body size | |||||||||

| 20 | 30 | 40 | 60 | ||||||

| (6) | Semi-standard | g | Exhaust mechanism | No symbol | Relieving type | ● | ● | ● | ● |

| N | Non-relieving type | ● | ● | ● | ● | ||||

| h | Flow direction | No symbol | Flow direction: left → right | ● | ● | ● | ● | ||

| R | Flow direction: right → left | ● | ● | ● | ● | ||||

| i | Pressure unit | No symbol | Name plate, bowl caution plate and pressure gauge units: MPa | ● | ● | ● | ● | ||

| Z Note 17) | Name plate, bowl caution plate and pressure gauge units: psi, °F | ○ Note 19) | ○ Note 19) | ○ Note 19) | ○ Note 19) | ||||

| ZA Note 18) | Digital pressure switch: with unit selection function | △ Note 20) | △ Note 20) | △ Note 20) | △ Note 20) | ||||

Note 1) Set the inlet pressure to at least 0.05‑MPa higher than the set pressure.

Note 2) Drain guide is NPT1/8 (applicable to the AW20(K)-B); and NPT1/4 (applicable to the AW30(K)-B to AW60(K)-B). The auto drain port comes with ø3/8" one-touch fitting (applicable to the AW30(K)-B to AW60(K)-B).

Note 3) Drain guide is G1/8 (applicable to the AW20(K)-B); and G1/4 (applicable to the AW30(K)-B to AW60(K)-B).

Note 4) Options B, G, H, M are not assembled and are supplied loose at the time of shipment.

Note 5) Set nuts are included with the bracket. (Applicable to the AW20(K)-B to AW40(K)-B). The AW60(K)-B has mounting screws (2 pcs.) included.

Note 6) When pressure is not applied, condensate which does not start the auto drain mechanism will remain in the drain bowl. Therefore manual release before ending operations is recommended.

Note 7) If the compressor used is small (0.75 kW, discharge flow rate is less than 100 L/min [ANR]), air leakage from the drain cock may occur when operations start. As such an N.C. type is recommended.

Note 8) When the pressure gauge is attached, a 1.0‑MPa specification will be fitted for standard (0.85‑MPa setting) type; 0.4 MPa for the 0.2‑MPa type.

Note 9) When choosing with H (panel mount), the installation space for lead wires will not be secured. In this case, select "wiring top entry" for the electrical entry.

Note 10) Pressure can be set higher than the specification pressure in some cases, but use with the pressure within the specified range.

Note 11) For chemical resistance of the bowl, refer to the table below "Effects of atmosphere of organic solvents and chemicals and where these elements are likely to adhere to the equipment. Chemical data for substances causing degradation (Reference)."

Note 12) A bowl guard is provided as standard (polycarbonate).

Note 13) A bowl guard is provided as standard (nylon).

Note 14) Float type auto drain: Cannot be selected in combination with C, D.

Note 15) Does not include a valve function.

Note 16) Metal bowl: Cannot be selected in combination with 2, 8.

Note 17) Thread type: NPT is applicable. Under new Japanese measurement laws, this product is only available for sale outside of Japan (SI units are used in Japan). Round-type pressure gauge (with color zone): cannot be used in combination with M. Available on request as separate, special order. The digital pressure switch, which has the unit selection function, has an default setting of psi.

Note 18) Options: E1, E2, E3, E4. Under new Japanese measurement laws, this product is only available for sale outside of Japan (SI units are used in Japan).

Note 19) ○ is for thread type NPT only.

Note 20) △: Combination available for options E1, E2, E3, E4.

Effects of atmosphere of organic solvents and chemicals and where these elements are likely to adhere to the equipment. Chemical data for substances causing degradation (Reference)

| Type | Chemical name | Application examples | Materials | |

|---|---|---|---|---|

| Polycarbonate | Nylon | |||

| Acid | Hydrochloric acid Sulfuric acid, Phosphoric acid Chromic acid | Acid washing liquid for metals | Possible use | × |

| Alkaline | Sodium hydroxide (caustic soda) Potassium hydroxide Calcium hydroxide Ammonia water Sodium carbonate | Degreasing of metals Industrial salts Water-soluble cutting oil | × | ○ |

| Inorganic salts | Sodium sulfide Potassium nitrate Sodium sulfate | - | × | Possible use |

| Chlorinated solvents | Carbon tetrachloride Chloroform Ethylene chloride Methylene chloride | Cleansing liquid for metals Printing ink Dilution | × | Possible use |

| Aromatic series | Benzene Toluene Paint thinner | Coatings Dry cleaning | × | Possible use |

| Ketone | Acetone Methyl ethyl ketone Cyclohexane | Photographic film Dry cleaning Textile industries | × | × |

| Alcohol | Ethyl alcohol IPA Methyl alcohol | Antifreeze Adhesive | Possible use | × |

| Oil | Gasoline Kerosene | - | × | ○ |

| Ester | Phthalic acid dimethyl Phthalic acid diethyl Acetic acid | Synthetic oil Anti-rust additives | × | ○ |

| Ether | Methyl ether Ethyl ether | Brake oil additives | × | ○ |

| Amino | Methyl amino | Cutting oil Brake oil additives Rubber accelerator | × | × |

| Other | Thread-lock fluid Seawater Leak tester | - | × | Possible use |

○: Essentially safe △: Some effects may occur ×: Effects will occur

- *When the above factors are present, or if there is some doubt, use a metal bowl for safety.

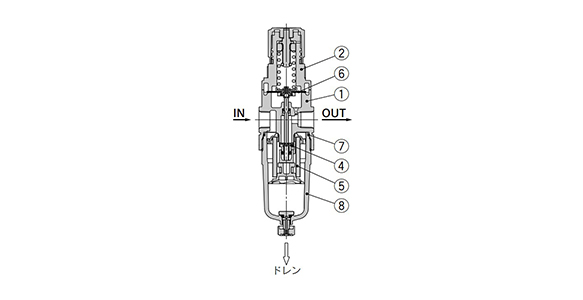

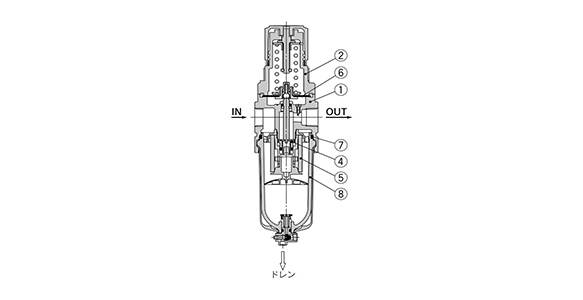

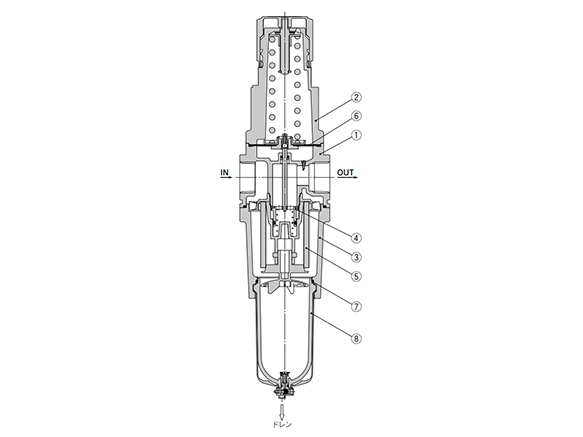

Structural Drawings

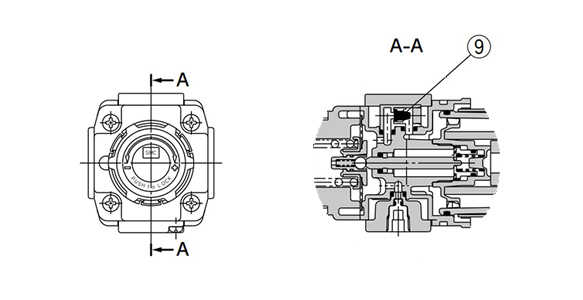

AW20(K)-B: structural drawings

AW30(K)-B/AW40(K)-B: structural drawings

AW60(K)-B: structural drawings

AW20K-B to AW60K-B (Filter Regulator With Backflow Function): structural drawings

Component Parts

| Number | Part name | Materials | Model | Additional notes |

|---|---|---|---|---|

| 1 | Body | Die-cast aluminum | AW20-B AW60-B | Urban white |

| 2 | Bonnet | Polyacetal | AW20-B to AW40-B | Urban white |

| Die-cast aluminum | AW60-B | Urban white | ||

| 3 | Housing | Die-cast aluminum | AW60-B | Urban white |

Replacement Parts

| Number | Part name | Materials | Part number | ||||

|---|---|---|---|---|---|---|---|

| AW20(K)-B | AW30(K)-B | AW40(K)-B | AW40(K)-06-B | AW60(K)-B | |||

| 4 | Valve assembly | Brass, HNBR | AW20P-340AS | AW30P-340AS | AW40P-340AS | AW60P-090AS | |

| 5 | Filter element | Non‐woven fabric | AF20P-060S | AF30P-060S | AF40P-060S | AW60P-060S | |

| 6 | Diaphragm assembly | Weatherable NBR | AR20P-150AS | AR30P-150AS | AR40P-150AS | AR50P-150AS | |

| 7 | Bowl seal | NBR | C2SFP-260S | C32FP-260S | C42FP-260S | ||

| 8 | Bowl assembly Note 1) | Polycarbonate | C2SF-A | C3SF-ANote 2) | C4SF-ANote 2) | ||

| 9 | Check valve assembly Note 3) | - | AR23KP-020AS | ||||

Note 1) The bowl assembly includes a bowl O-ring. Contact the manufacturer separately for psi, °F unit display specifications.

Note 2) Bowl assembly for the AW30(K)-B to AW60(K)-B models comes with a bowl guard (made of polycarbonate).

Note 3) Check valve assembly is applicable only for specifications with the backflow function (AW20(K)-B to AW60(K)-B). Assembly consisting of a check valve cover, check valve body and mounting screws (2 pcs.).

Filter Regulator AW20-B To AW60-B And Filter Regulator With Backflow Function AW20K-B To AW60K-B Dimensions

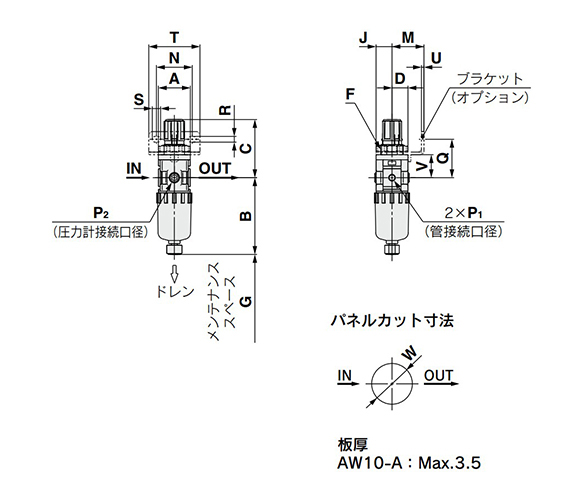

AW20(K)-B

(Unit: mm)

AW20(K)-B: dimensional drawings

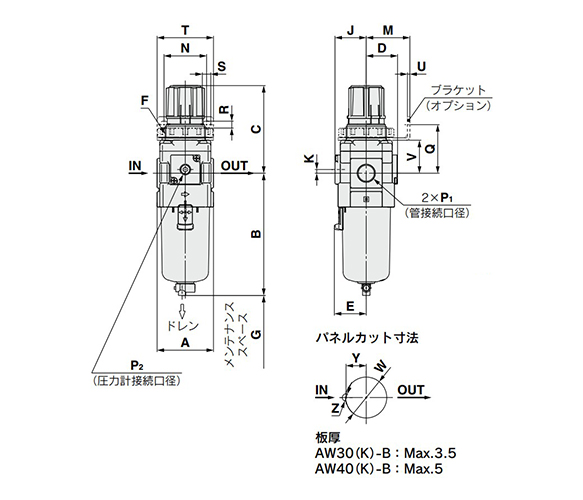

AW30(K)-B to AW40(K)-06-B

(Unit: mm)

AW30(K)-B to AW40(K)-06-B: dimensional drawing

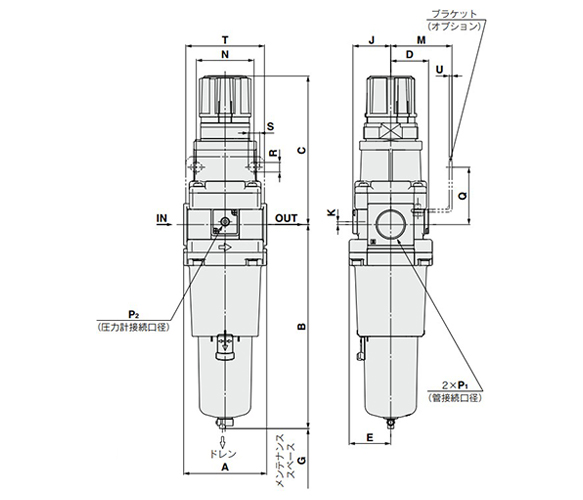

AW60(K)-B

(Unit: mm)

AW60(K)-B: dimensional drawing

(Unit: mm)

| Option | Square embedded type pressure gauge | Digital pressure switch | Round-type pressure gauge | Round-type pressure gauge (with color zone) |

|---|

| Compatible models | AW20(K)-B | AW20(K)-B | AW30(K)-B to AW60(K)-B | ||

|---|---|---|---|---|---|

| Option / Semi-standard specifications | With auto-drain (N.C.) | Metal bowl | With drain guide | Metal bowl with drain guide | With auto-drain (N.O./N.C.) |

| Compatible models | AW30(K)-B to AW60(K)-B | |||||

|---|---|---|---|---|---|---|

| Option / Semi-standard specifications | Metal bowl | Metal bowl with drain guide | Metal bowl with level gauge | Metal bowl with drain guide with level gauge | With drain guide | Drain cock with barb fitting |

(Unit: mm)

| Model | Standard specification | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| P 1 | P 2 | A | B | C Note) | D | E | F | G | J | K | |

| AW20(K)-B | 1/8, 1/4 | 1/8 | 40 | 87.6 | 72.4 | 26 | - | M28 × 1 | 40 | 26 | 5 |

| AW30(K)-B | 1/4, 3/8 | 1/8 | 53 | 115.1 | 85.6 | 29.4 | 30 | M38 × 1.5 | 55 | 29.4 | 3.5 |

| AW40(K)-B | 1/4, 3/8, 1/2 | 1/8 | 70 | 147.1 | 91.7 | 37.3 | 38.4 | M42 × 1.5 | 80 | 37.3 | 1.5 |

| AW40(K)-06-B | 3/4 | 1/8 | 75 | 149.1 | 93.2 | 37.3 | 38.4 | M42 × 1.5 | 80 | 37.3 | 1.2 |

| AW60(K)-B | 3/4, 1 | 1/8 | 95 | 234.1 | 175.5 | 43.3 | 47.5 | - | 30 | 43.3 | 3.2 |

| Model | Option specification | |||||||

|---|---|---|---|---|---|---|---|---|

| Square type pressure gauge | Digital pressure switch | Round-type pressure gauge | Round-type pressure gauge (with color zone) | |||||

| H | J | H | J | H | J | H | J | |

| AW20(K)-B | □28 | 27 | □27.8 | 37.5 | ø37.5 (diameter 37.5 mm) | 62.5 | ø37.5 (diameter 37.5 mm) | 63.5 |

| AW30(K)-B | □28 | 30.4 | □27.8 | 40.9 | ø37.5 (diameter 37.5 mm) | 65.9 | ø37.5 (diameter 37.5 mm) | 66.9 |

| AW40(K)-B | □28 | 38.3 | □27.8 | 48.8 | ø42.5 (diameter 42.5 mm) | 74.8 | ø42.5 (diameter 42.5 mm) | 74.8 |

| AW40(K)-06-B | □28 | 38.3 | □27.8 | 48.8 | ø42.5 (diameter 42.5 mm) | 74.8 | ø42.5 (diameter 42.5 mm) | 74.8 |

| AW60(K)-B | □28 | 44.3 | □27.8 | 61.3 | ø42.5 (diameter 42.5 mm) | 80.8 | ø42.5 (diameter 42.5 mm) | 80.8 |

| Model | Option specification | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bracket mounting dimensions | Panel mount | With auto drain | ||||||||||

| M | N | Q | R | S | T | U | V | W | Y | Z | B | |

| AW20(K)-B | 30 | 34 | 43.9 | 5.4 | 15.4 | 55 | 2.3 | 29.7 | 28.5 | 14 | 6 | 104.9 |

| AW30(K)-B | 41 | 40 | 45.8 | 6.5 | 8 | 53 | 2.3 | 31.1 | 38.5 | 19 | 7 | 156.8 |

| AW40(K)-B | 50 | 54 | 54 | 8.5 | 10.5 | 70 | 2.3 | 35.5 | 42.5 | 21 | 7 | 186.9 |

| AW40(K)-06-B | 50 | 54 | 55.5 | 8.5 | 10.5 | 70 | 2.3 | 37 | 42.5 | 21 | 7 | 188.9 |

| AW60(K)-B | 70 | 66 | 65.8 | 11 | 13 | 90 | 3.2 | - | - | - | - | 273.9 |

| Model | Semi-standard specifications | |||||

|---|---|---|---|---|---|---|

| With barb fittings | With drain guide | Metal bowl | Metal bowl with drain guide | Metal bowl with level gauge | Metal bowl with level gauge with drain guide | |

| B | B | B | B | B | B | |

| AW20(K)-B | - | 91.4 | 87.4 | 93.9 | - | - |

| AW30(K)-B | 123.6 | 121.9 | 117.6 | 122.1 | 137.6 | 142.1 |

| AW40(K)-B | 155.6 | 153.9 | 149.6 | 154.1 | 169.6 | 174.1 |

| AW40(K)-06-B | 157.6 | 155.9 | 151.6 | 156.1 | 171.6 | 176.1 |

| AW60(K)-B | 240.9 | 242.6 | 236.6 | 241.1 | 256.6 | 261.1 |

Note) The dimension C is the length when the filter regulator knob (handle) is unlocked.

| Part Number |

|---|

| AW30-02DE1-B |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to Ship | Connection Dia. | Case Material | Case Guard | Exhaust Structure | Flow Direction | Drain Cock | Pressure Gauge | Size of Body | Set Pressure | Drain Outlet | Pressure Unit | Made to order specifications | Filter regulator backflow function | Accessories |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | Quote | Rc1/4 | [Plastic] Polycarbonate Case | Presence | Relief type | [Standard Flow (Left to Right)] Standard Flow (Left to Right) | [Auto/Manual] N.O. (Normally Open) at non-pressurized with drain emissions | [With Pressure Switch] Digital pressure switch | 30 | 0.05 to 0.85 MPa | With drain cock | Product name plate, case caution display, pressure gauge unit notation: MPa | None | None | None |

Loading...

Basic Information

| Regulator Unit Combination | Filter Regulator | Filter, Filtration Level | 5μm | Compressed Air Quality | General Dry Air |

|---|---|---|---|---|---|

| Max. Operating Pressure(MPa) | 1 |

Please check the type/dimensions/specifications of the part AW30-02DE1-B in the Filter Regulator AW20 to 60-B, Filter Regulator With Backflow Function AW20K to 60K-B series.

Specification/Dimensions

-

type

- AW20

- AW20K

- AW30

- AW30K

- AW40

- AW40K

- AW60

- AW60K

-

Connection Dia.

- Rc1/8

- Rc1/4

- Rc3/8

- Rc1/2

- Rc3/4

- Rc1

- NPT1/4

- NPT3/8

- G1/4

- G3/8

- NPT1/2

- NPT3/4

- NPT1/8

- NPT1

- G1/8

- G1/2

- G3/4

- G1

-

Case Material

- Plastic

- Metal

- Plastic

-

Case Guard

- No

- Presence

-

Exhaust Structure

- Non-relief type

- Relief type

-

Flow Direction

- Standard Flow (Left to Right)

- Reverse Flow (Right to Left)

- Standard Flow (Left to Right)

-

Drain Cock

- Manual

- Auto/Manual

- Not Provided

- Manual

-

Pressure Gauge

- No (No Pressure Port Plug)

- With Standard Pressure Gauge

- With Pressure Switch

-

Size of Body

-

Set Pressure

- 0.02 to 0.2 MPa

- 0.05 to 0.4 MPa

- 0.05 to 0.85 MPa

- 0.1 to 1.7 MPa

-

Drain Outlet

- Drain guide 1/4

- Drain guide 1/8

- Drain cock with barb fitting

- With drain cock

-

Pressure Unit

- Digital pressure switch:having unit switching function

- Product name plate, case caution display, pressure gauge unit notation: MPa

- Product name plate, case caution display, pressure gauge unit notation: psi, °F

-

Made to order specifications

- 0.4‑MPa setting

- 1 to 5 V output with digital pressure switch

- 4 to 20 mA output with digital pressure switch

- For Low-Temperature Environment

- Long bowl compatible

- None

- Suitable for high pressure

- Used under high temperature

- With digital pressure switch (NPN output)

- With digital pressure switch (PNP output)

-

Filter regulator backflow function

- None

- Yes

-

Accessories

- None

- With Bracket

- With set nut (for panel mount)

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- Same day

- 21 Day(s) or Less

- 22 Day(s) or Less

- 32 Day(s) or Less

- 41 Day(s) or Less

- 42 Day(s) or Less

- 61 Day(s) or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Similar Part Numbers

| Part Number |

|---|

| AW20-01-2-B |

| AW20-01-2N-B |

| AW20-01-6-B |

| AW30-02DE1-R-B |

| AW30-02DE1H-B |

| AW30-02DE3-8-B |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to Ship | Connection Dia. | Case Material | Case Guard | Exhaust Structure | Flow Direction | Drain Cock | Pressure Gauge | Size of Body | Set Pressure | Drain Outlet | Pressure Unit | Made to order specifications | Filter regulator backflow function | Accessories |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

SGD 78.05 | 1 Piece(s) | 32 Day(s) | Rc1/8 | [Metal] Metal Case | No | Relief type | [Standard Flow (Left to Right)] Standard Flow (Left to Right) | [Manual] Manual | No (No Pressure Port Plug) | 20 | 0.05 to 0.85 MPa | With drain cock | Product name plate, case caution display, pressure gauge unit notation: MPa | None | None | None | ||

SGD 78.05 | 1 Piece(s) | 32 Day(s) | Rc1/8 | [Metal] Metal Case | No | Non-relief type | [Standard Flow (Left to Right)] Standard Flow (Left to Right) | [Manual] Manual | No (No Pressure Port Plug) | 20 | 0.05 to 0.85 MPa | With drain cock | Product name plate, case caution display, pressure gauge unit notation: MPa | None | None | None | ||

- | 1 Piece(s) | Quote | Rc1/8 | [Plastic] Nylon Case | No | Relief type | [Standard Flow (Left to Right)] Standard Flow (Left to Right) | [Manual] Manual | No (No Pressure Port Plug) | 20 | 0.05 to 0.85 MPa | With drain cock | Product name plate, case caution display, pressure gauge unit notation: MPa | None | None | None | ||

- | 1 Piece(s) | Quote | Rc1/4 | [Plastic] Polycarbonate Case | Presence | Relief type | [Reverse Flow (Right to Left)] Reverse Flow (Right to Left) | [Auto/Manual] N.O. (Normally Open) at non-pressurized with drain emissions | [With Pressure Switch] Digital pressure switch | 30 | 0.05 to 0.85 MPa | With drain cock | Product name plate, case caution display, pressure gauge unit notation: MPa | None | None | None | ||

- | 1 Piece(s) | Quote | Rc1/4 | [Plastic] Polycarbonate Case | Presence | Relief type | [Standard Flow (Left to Right)] Standard Flow (Left to Right) | [Auto/Manual] N.O. (Normally Open) at non-pressurized with drain emissions | [With Pressure Switch] Digital pressure switch | 30 | 0.05 to 0.85 MPa | With drain cock | Product name plate, case caution display, pressure gauge unit notation: MPa | None | None | With set nut (for panel mount) | ||

- | 1 Piece(s) | Quote | Rc1/4 | [Metal] Metal Case with Level Gauge | Presence | Relief type | [Standard Flow (Left to Right)] Standard Flow (Left to Right) | [Auto/Manual] N.O. (Normally Open) at non-pressurized with drain emissions | [With Pressure Switch] Digital pressure switch | 30 | 0.05 to 0.85 MPa | With drain cock | Product name plate, case caution display, pressure gauge unit notation: MPa | None | None | None |

How can we improve?

How can we improve?