(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla Firefox.

50,000 Stock items for Same Day Ship Out.

All Categories

Categories

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Application

Brands

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Compact Cylinder, Standard Type, Single Acting, Single Rod CQS Series (CQSL16-5TM)

Compact Cylinder, Standard Type, Double Single, Single Rod CQS Series that allows 2-way basic mounting.

[Features]

· Ideal for machine designs with small space requirements.

· Square body shape that gives you flexibility for designing machines.

· Auto switch mounting direction allows for flexible design requirements.

· Non-rotating rod with high non-rotating accuracy.

(i)Caution

- See catalog for specification details.

- Product pictures are representations. CAD data is not supported for some model numbers.

Part Number

Configured Part Number is shown.

CQSL16-5TM

Compact Cylinder, Standard Type, Single Acting, Single Rod CQS Series Specifications

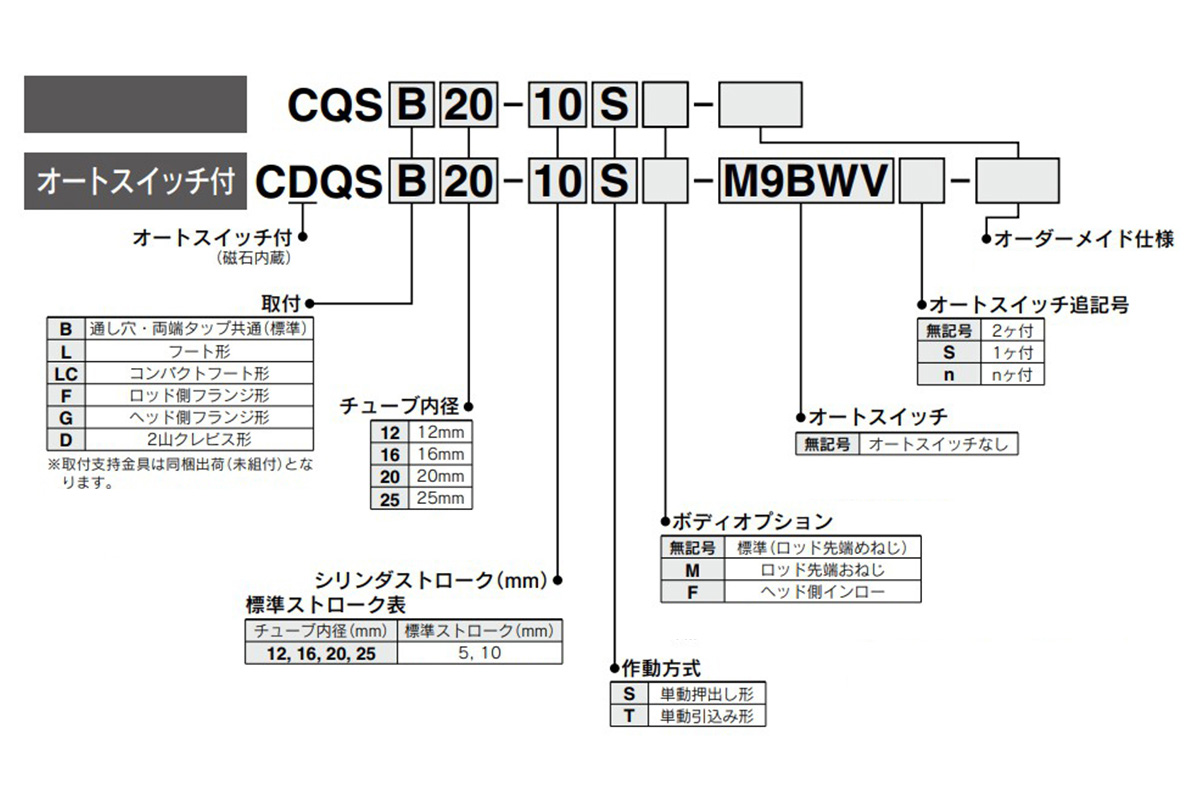

Model Number Notation

Model Number Notation

Standard specification

| Tube Internal Diameter (mm) | 12 | 16 | 20 | 25 |

|---|---|---|---|---|

| Operating method | Single acting, single rod | |||

| Applicable fluids | Air | |||

| Lubrication | Not required (non-lube) | |||

| Proof pressure | 1.5 MPa | |||

| Maximum operating pressure | 1.0 MPa | |||

| Minimum operating pressure | 0.25 MPa | 0.18 MPa | ||

| Ambient and working fluid temperature | Without auto switch: -10°C to 70°C (No freezing) | |||

| With auto switch: -10°C to 60°C (No freezing) | ||||

| Cushioning | None | |||

| Rod-end thread | Female thread | |||

| Stroke length tolerance | +1.0 mm 0 | |||

| Operating piston speed | 50 to 500 mm/s | |||

| Allowable kinetic energy J | 0.022 | 0.038 | 0.055 | 0.09 |

Theoretical Output List

(N)

| Operating method | Bore size (mm) | Rod diameter (mm) | Operating Direction | Piston area (mm2) | Operating pressure (MPa) | Retracted side | Extended side | ||

|---|---|---|---|---|---|---|---|---|---|

| 0.3 | 0.5 | 0.7 | |||||||

| Spring return | 12 | 6 | IN | - | 20 | 43 | 65 | 14 | 4 |

| OUT | 113 | ||||||||

| 16 | 8 | IN | - | 45 | 86 | 126 | 15 | 6 | |

| OUT | 201 | ||||||||

| 20 | 10 | IN | - | 78 | 141 | 204 | 15 | 6 | |

| OUT | 314 | ||||||||

| 25 | 12 | IN | - | 126 | 224 | 323 | 21 | 11 | |

| OUT | 491 | ||||||||

| Spring extend | 12 | 6 | IN | 84.8 | 14 | 31 | 48 | 10 | 3 |

| OUT | - | ||||||||

| 16 | 8 | IN | 151 | 24 | 54 | 85 | 19 | 4 | |

| OUT | - | ||||||||

| 20 | 10 | IN | 236 | 44 | 91 | 138 | 27 | 5 | |

| OUT | - | ||||||||

| 25 | 12 | IN | 378 | 84 | 160 | 235 | 29 | 10 | |

| OUT | - | ||||||||

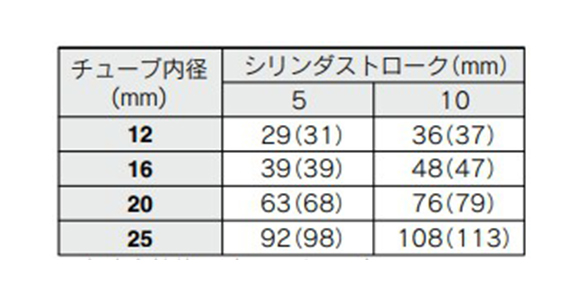

Weight List / Without Auto Switch, Spring Return (Spring Extend)

(g)

Weight List / Without Auto Switch, Spring Return (Spring Extend)

- *(): Denotes the values of spring extend.

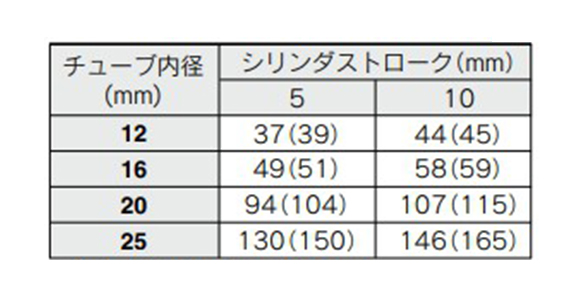

Weight List / With Auto Switch (Built-In Magnet), Spring Return (Spring Extend)

(g)

Weight List / With Auto Switch (Built-In Magnet), Spring Return (Spring Extend)

- *(): Denotes the values of spring extend.

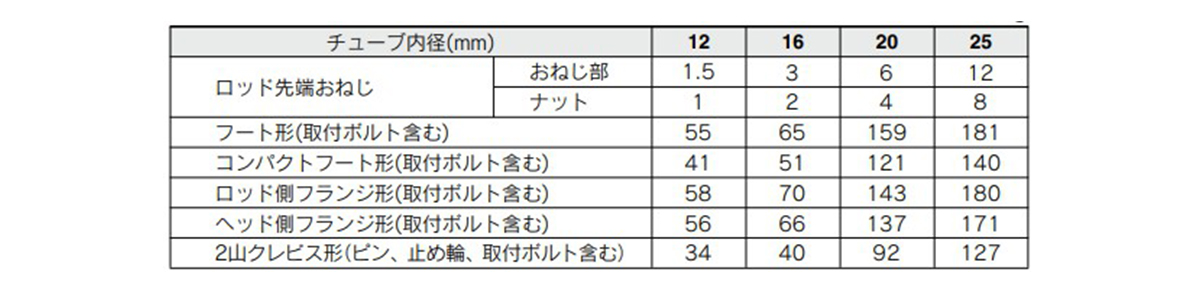

Additional Weight List

(g)

Additional Weight List

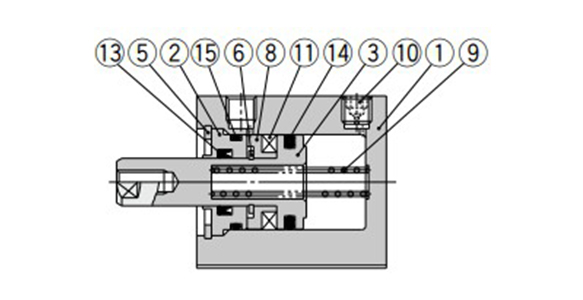

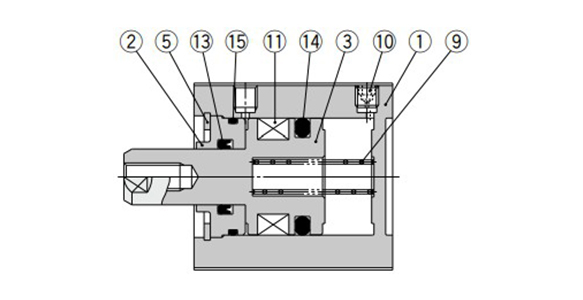

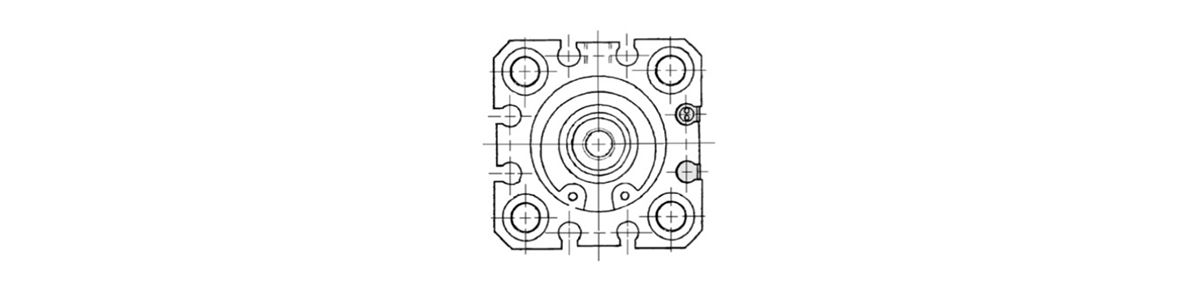

Structural drawing examples

With auto switch (built-in magnet), single acting spring extend type: ø12 (12‑mm bore size) / ø16 (16‑mm bore size)

With auto switch (built-in magnet), single acting spring extend type: ø20 (20‑mm bore size) / ø25 (25‑mm bore size)

Component Parts

| Number | Part name | Material | Note |

|---|---|---|---|

| 1 | Cylinder tube | Aluminum Alloy | Hard Anodize |

| 2 | Collar | Aluminum Alloy | Anodized |

| 3 | Piston | Aluminum Alloy | Single acting, spring return |

| Stainless steel | Single acting, spring extend | ||

| 4 | Piston rod | Stainless steel | - |

| 5 | Retaining Ring | Carbon tool steel | Phosphate coated |

| 6 | Retaining Ring | Carbon tool steel | Nickel plating |

| 7 | Rod-end nut | Carbon steel | Zinc chromate |

| 8 | Spacer for switch type | Aluminum Alloy | Chromate |

| 9 | Return spring | Piano wire | Zinc chromate |

| 10 | Plug with fixed orifice | Alloy steel | Nickel plating |

| 11 | Magnet | - | - |

| 12 | Centering location ring | Aluminum Alloy | Anodized |

| 13 | Rod Gasket | NBR | - |

| 14 | Piston Gasket | NBR | - |

| 15 | Tube gasket | NBR | - |

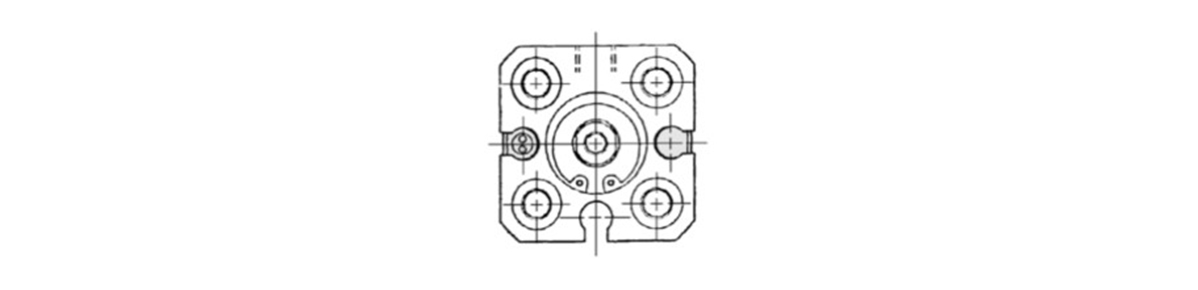

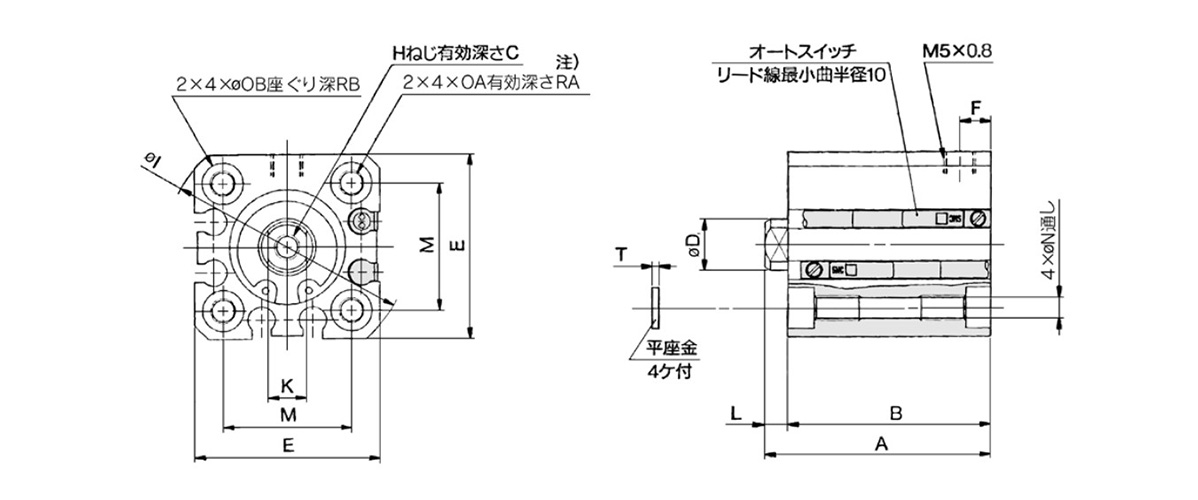

Compact Cylinder, Standard Type, Single Acting, Single Rod CQS Series Dimensions

Standard type (through-hole / both ends tapped common): ø12 (12‑mm bore size) dimensional drawing

(Unit: mm)

Standard type (through-hole / both ends tapped common): ø16 (16‑mm bore size) dimensional drawing

Standard type (through-hole / both ends tapped common): ø20/ø25 (20/25‑mm bore size) dimensional drawing

| Bore size (mm) | Stroke range (mm) | Without auto switch | With auto switch | C | D | E | F | H | I | K | L | M | N | OA | OB | RA | RB | T | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | A | B | |||||||||||||||||||||

| 5ST | 10ST | 5ST | 10ST | 5ST | 10ST | 5ST | 10ST | |||||||||||||||||

| 12 | 5, 10 | 25.5 | 30.5 | 22 | 27 | 30.5 | 35.5 | 27 | 32 | 6 | 6 | 25 | 5 | M3 × 0.5 | 32 | 5 | 3.5 | 15.5 | 3.5 | M4 × 0.7 | 6.5 | 7 | 4 | 0.5 |

| 16 | 25.5 | 30.5 | 22 | 27 | 30.5 | 35.5 | 27 | 32 | 8 | 8 | 29 | 5 | M4 × 0.7 | 38 | 6 | 3.5 | 20 | 3.5 | M4 × 0.7 | 6.5 | 7 | 4 | 0.5 | |

| 20 | 29 | 34 | 24.5 | 29.5 | 39 | 44 | 34.5 | 39.5 | 7 | 10 | 36 | 5.5 | M5 × 0.8 | 47 | 8 | 4.5 | 25.5 | 5.4 | M6 × 1.0 | 9 | 10 | 7 | 1 | |

| 25 | 32.5 | 37.5 | 27.5 | 32.5 | 42.5 | 47.5 | 37.5 | 42.5 | 12 | 12 | 40 | 5.5 | M6 × 1.0 | 52 | 10 | 5 | 28 | 5.4 | M6 × 1.0 | 9 | 10 | 7 | 1 | |

Note) For the following bore/stroke sizes, the through-hole is threaded: Standard type: ø12 (12‑mm bore size), ø16 (16‑mm bore size) 5 stroke.

Standard type: ø20 (20‑mm bore size), ø25 (25‑mm bore size) 5 and 10 stroke.

With auto switch and built-in magnet: ø20 (20‑mm bore size) 5 stroke.

| Part Number |

|---|

| CQSL16-5TM |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to Ship | Cylinder Operation Method | Cylinder (Tube) Inner Diameter (Ø) | Stroke (mm) | Operating Pressure (MPa) | Specifications | Body Options | Auto Switches | Lead Wire | The number of the switches | Type of Mount Support | Rod Tip Shape | Custom-made Specifications |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | Quote | [Single-Action (Retraction)] Special Single-acting(Retracted by External Force) | 16 | 5 | 0.25 to 1.0 | Without magnet | - | - | - | - | Foot | Male rod end | None |

Loading...

Basic Information

| Rod Operation Method | Single Rods | Main Body Shape | Plate Cylinder | Additional Function | High rigidity / high precision high class guide |

|---|---|---|---|---|---|

| Environment, Applications | Standard | Cushion | None |

Please check the type/dimensions/specifications of the part CQSL16-5TM in the Compact Cylinder, Standard Type, Single Acting, Single Rod CQS Series series.

Specification/Dimensions

-

Body Options

-

Auto Switches

-

Lead Wire

- 0.5

- 0.5 (M8 3-pin plug connector)

- 0.5 (M8 4-pin plug connector)

- 0.5 (M12 4-pin A-cord [normal-key] plug connector)

- 1

- 3

- 5

-

The number of the switches

-

type

- CDQS

- CQS

-

Cylinder Operation Method

- Single Acting (Extruded)

- Single-Action (Retraction)

-

Cylinder (Tube) Inner Diameter(Ø)

-

Stroke(mm)

-

Operating Pressure(MPa)

-

Specifications

- Built-in magnet

- Without magnet

-

Type of Mount Support

- Compact foot type

- Foot

- Head-end flange

- Rod-end flange type

- Through-Hole / Both Ends Tapped Common (Standard)

- U-Shaped Clevis Type

-

Rod Tip Shape

- Female rod end

- Male rod end

-

Custom-made Specifications

- Fluoroelastomer seals

- Intermediate stroke (using dedicated body)

- None

- Piston rod, retaining ring, rod-end nut made of stainless steel

- Piston rod, retaining ring, rod-end nut made of stainless steel + fluoroelastomer seals

- With boss on rod side

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- 31 Day(s) or Less

- 32 Day(s) or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Similar Part Numbers

| Part Number |

|---|

| CDQSB12-10S-A90S |

| CDQSB12-10S-A90V |

| CDQSB12-10S-A90VL |

| CQSL20-10S |

| CQSL20-10SM |

| CQSL20-10T |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to Ship | Cylinder Operation Method | Cylinder (Tube) Inner Diameter (Ø) | Stroke (mm) | Operating Pressure (MPa) | Specifications | Body Options | Auto Switches | Lead Wire | The number of the switches | Type of Mount Support | Rod Tip Shape | Custom-made Specifications |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | Quote | Single Acting (Extruded) | 12 | 10 | 0.25 to 1.0 | Built-in magnet | - | A90 | 0.5 | 1 | Through-Hole / Both Ends Tapped Common (Standard) | Female rod end | None | ||

- | 1 Piece(s) | Quote | Single Acting (Extruded) | 12 | 10 | 0.25 to 1.0 | Built-in magnet | - | A90V | 0.5 | 2 | Through-Hole / Both Ends Tapped Common (Standard) | Female rod end | None | ||

- | 1 Piece(s) | Quote | Single Acting (Extruded) | 12 | 10 | 0.25 to 1.0 | Built-in magnet | - | A90V | 3 | 2 | Through-Hole / Both Ends Tapped Common (Standard) | Female rod end | None | ||

- | 1 Piece(s) | Quote | Single Acting (Extruded) | 20 | 10 | 0.18 to 1.0 | Without magnet | - | - | - | - | Foot | Female rod end | None | ||

- | 1 Piece(s) | Quote | Single Acting (Extruded) | 20 | 10 | 0.18 to 1.0 | Without magnet | - | - | - | - | Foot | Male rod end | None | ||

- | 1 Piece(s) | Quote | [Single-Action (Retraction)] Special Single-acting(Retracted by External Force) | 20 | 10 | 0.18 to 1.0 | Without magnet | - | - | - | - | Foot | Female rod end | None |

How can we improve?

How can we improve?