(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla Firefox.

50,000 Stock items for Same Day Ship Out.

All Categories

Categories

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Application

Brands

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

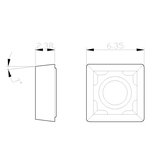

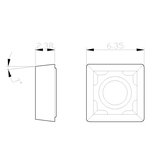

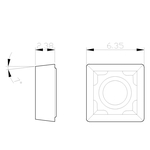

Turning Inserts(Shape:S (Rectangular))

[What is turning?]

A shape is created by rotating the work material and cutting the surface while pressing the cutting edge. Processing methods can be divided into outer diameter processing, threading, inner diameter processing, and cut-off processing. The model numbers written on the insert and holder are codes unique to each tool manufacturer. Understanding how to read the model number provides basic information such as shape, type, and size. In many cases, cutting conditions are written on the label of the insert case, so check it before use.

| Days to Ship |

|

|---|

-

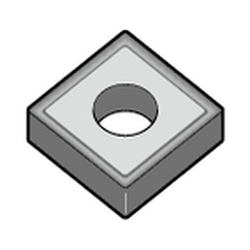

T-Max P insert for turning, Square, Lathe Negative Tip, SNMA/SNMG/SNMM

SANDVIK

[Features]

Carbide-coated insert

Square-shaped insert

Negative insert

For machining general steel

For semi-finishingStandard Price: SGD 9.70- Days to Ship: 8 Day(s) or more -

BIG DAISHOWA SEIKI

[Features]

· Throw-away insert that is ideal for specially designed boring machiningStandard Price: SGD 6.90- Days to Ship: 8 Day(s) or more -

Standard Price: SGD 16.30 Days to Ship: 10 Day(s) -

KYOCERA

[Specifications]

· Shape: S (Quadrilateral)

· Rake Angle: Negative

· Handedness: No handedness

[Applications]

· Machining Applications: For Outer Diameter / Inner DiameterStandard Price: SGD 7.71- Days to Ship: 6 Day(s) or more -

Standard Price: SGD 9.39- Days to Ship: 4 Day(s) or more -

Standard Price: SGD 17.23- Days to Ship: 8 Day(s) or more -

Square 90°, Negative, with Hole SNMG1204○○ "Rough Cutting"

KYOCERA

[Specifications]

· Shape: S (Quadrilateral)

· Number of Available Corners: 8

· Rake Angle: Negative

· Handedness: No handedness

[Applications]

· Machining Applications: For Outer Diameter / Inner Diameter

· Breaker Application: Medium CuttingStandard Price: SGD 9.72- Days to Ship: 3 Day(s) or more -

KYOCERA

[Specifications]

· Shape: S (Quadrilateral)

· Rake Angle: Negative

· Handedness: No handedness

[Applications]

· Machining Applications: For Outer Diameter / Inner DiameterStandard Price: SGD 10.87- Days to Ship: 6 Day(s) or more -

SANDVIK

[Features]

T-Max S, carbide-coated insert for general machining

Precision class

Square-shaped insert

Positive insert

For general steel machining

Without breakerStandard Price: SGD 9.72- Days to Ship: 8 Day(s) or more -

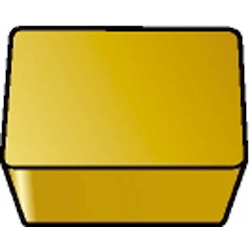

CoroTurn 107 Positive Insert For Turning (Square Shaped 90°)

SANDVIK

[Features]

A carbide-coated insert for machining the general inner diameters and outer diameters of small components

Square-shaped insert

Positive insert

For machining stainless steel

For finishingStandard Price: SGD 12.05- Days to Ship: 8 Day(s) or more -

SANWA SEISAKUSYO

[Features]

· Superior to other material inserts in terms of toughness and ideal for intermittent cutting and machining that does not require increased rotational speed of the workpiece.Standard Price: SGD 54.15- Days to Ship: 7 Day(s) or more -

Standard Price: SGD 282.20- Days to Ship: 15 Day(s) or more -

Standard Price: SGD 17.69- Days to Ship: 8 Day(s) or more -

S Type Square 90°, Negative with Hole SNMG120408-MTM20 "Intermediate Cutting"

MISUMI

[Features]

· Supports a wide range of work materials such as general steel, stainless steel and cast iron

· Provides extraordinary chipping resistance and long service life in general steel, intermediate cutting and intermittent machining

[Applications]

· Primarily recommended for general steel, intermediate cutting and intermittent machining.

· It exhibits chipping resistance in intermittent machining and versatility in cutting materials other than steel as well.

· It can be used in a wide range of fields.- Volume Discount

Standard Price: SGD 13.48 Days to Ship: 3 Day(s) or more -

Sumi Diamond Chip S (Square) SCMT

SUMITOMO ELECTRIC HARDMETAL

Diamond sintered insert for cutting tools developed with unique technology.

Standard Price: SGD 87.48 Days to Ship: 4 Day(s) or more -

Standard Price: SGD 13.81 Days to Ship: 4 Day(s) or more -

Standard Price: SGD 9.39 Days to Ship: 4 Day(s) or more -

Standard Price: SGD 11.04- Days to Ship: 4 Day(s) or more -

SUMITOMO ELECTRIC HARDMETAL

[Specifications]

·Chip Breaker Symbol: None

·Shape: (square)

· Groove

·Holes: N (No hole)

·Relief angle: Negative 0° (N) [Grade Features]

·BN250 is a general-purpose grade that has optimized CBN sintered compact composition and improved a balance of abrasion resistance and wear resistance.

·BN700 is one of grades that have the highest hardness and toughness in the SUMIBORON series, and has balanced abrasion resistance and wear resistance when cutting sintered alloys and cast iron, etc.

·NB90S is for finishing cast iron

·Grade for boring.

·T1200A is a cermet grade with high abrasion resistance for finishing to medium-rough cutting of general steel.Standard Price: SGD 11.04- Days to Ship: 4 Day(s) or more -

SUMITOMO ELECTRIC HARDMETAL

[Specifications]

·Chip Breaker Symbol: None

·Shape: (square)

· Groove

·Holes: A (With holes)

·Relief angle: Negative 0° (N) [Grade Features]

·AC410K is a general-purpose grade with an excellent balance of wear resistance and abrasion resistance.

·AC700G is a grade focusing on abrasion resistance that can be used for high to medium-speed cutting.

·BN250 is a general-purpose grade that has optimized CBN sintered compact composition and improved a balance of abrasion resistance and wear resistance.

·BN500 has an excellent balance of wear resistance and abrasion resistance, so it can achieve long tool lifespan in high-speed

·and high-precision machining of high grade cast iron such as ductile cast iron in particular.

·BN500 has an excellent balance of wear resistance and abrasion resistance, so it can achieve long tool lifespan in high-speed

·and high-precision machining of high grade cast iron such as ductile cast iron in particular.

·BN700 is one of grades that have the highest hardness and toughness in the SUMIBORON series, and has balanced abrasion resistance and wear resistance when cutting sintered alloys and cast iron, etc.Standard Price: SGD 9.77- Days to Ship: 4 Day(s) or more -

Standard Price: SGD 9.77- Days to Ship: 4 Day(s) or more -

Blade Tip Replacement Tip S (Square) SPGN

SUMITOMO ELECTRIC HARDMETAL

[Specifications]

·Chip Breaker Symbol: None

·Shape: (square)

· Groove

·Holes: N (No hole)

·Relief angle: Positive 11° (P) [Grade Features]

·BN250 is a general-purpose grade that has optimized CBN sintered compact composition and improved a balance of abrasion resistance and wear resistance.

·BN500 has an excellent balance of wear resistance and abrasion resistance, so it can achieve long tool lifespan in high-speed

·and high-precision machining of high grade cast iron such as ductile cast iron in particular.

·BN500 has an excellent balance of wear resistance and abrasion resistance, so it can achieve long tool lifespan in high-speed

·and high-precision machining of high grade cast iron such as ductile cast iron in particular.

·BN700 is one of grades that have the highest hardness and toughness in the SUMIBORON series, and has balanced abrasion resistance and wear resistance when cutting sintered alloys and cast iron, etc.

·BNX20 is a grade that demonstrates its power in high-efficiency machining.

·DA150 is a grade with an excellent balance of machinability and abrasion resistance, as the diamond particles are strongly bonded to each other.

·T1200A is a cermet grade with high abrasion resistance for finishing to medium-rough cutting of general steel.Standard Price: SGD 10.95- Days to Ship: 4 Day(s) or more -

Standard Price: SGD 9.49- Days to Ship: 4 Day(s) or more -

Standard Price: SGD 6.99- Days to Ship: 4 Day(s) or more -

Sumi Boron Chip S (Square) 2NC-SNGA

SUMITOMO ELECTRIC HARDMETAL

Unique CBN sintered tool (Sumiboron) insert. It possesses high hardness and exceptional heat resistance compared to conventional tool material.

Standard Price: SGD 64.24 Days to Ship: 4 Day(s) or more -

Sumi Boron Chip S (Square) 2NU-SNGA

SUMITOMO ELECTRIC HARDMETAL

Unique CBN sintered tool (Sumiboron) insert. It possesses high hardness and exceptional heat resistance compared to conventional tool material.

Standard Price: SGD 55.69- Days to Ship: 4 Day(s) or more -

Sumi Diamond Chip S (Square) NF-SCMT

SUMITOMO ELECTRIC HARDMETAL

Diamond sintered insert for cutting tools developed with unique technology.

Standard Price: SGD 77.48 Days to Ship: 4 Day(s) or more -

Sumi Diamond Chip S (Square) NF-SEGN

SUMITOMO ELECTRIC HARDMETAL

Diamond sintered insert for cutting tools developed with unique technology.

Standard Price: SGD 95.45- Days to Ship: 4 Day(s) or more -

Sumi Diamond Chip S (Square) NF-SPGN

SUMITOMO ELECTRIC HARDMETAL

Diamond sintered insert for cutting tools developed with unique technology.

Standard Price: SGD 89.70 Days to Ship: 4 Day(s) or more -

Sumi Boron Chip S (Square) NU-SNMA

SUMITOMO ELECTRIC HARDMETAL

Unique CBN sintered tool (Sumiboron) insert. It possesses high hardness and exceptional heat resistance compared to conventional tool material.

Standard Price: SGD 35.25- Days to Ship: 4 Day(s) or more -

Sumi Boron Chip S (Square) NU-SPGN

SUMITOMO ELECTRIC HARDMETAL

Unique CBN sintered tool (Sumiboron) insert. It possesses high hardness and exceptional heat resistance compared to conventional tool material.

Standard Price: SGD 38.88- Days to Ship: 4 Day(s) or more -

Sumi Boron Chip S (Square) T-2NU-SNGA

SUMITOMO ELECTRIC HARDMETAL

Unique CBN sintered tool (Sumiboron) insert. It possesses high hardness and exceptional heat resistance compared to conventional tool material.

Standard Price: SGD 50.88 Days to Ship: 4 Day(s) or more -

Standard Price: SGD 23.40 Days to Ship: 6 Day(s) or more -

Replacement Blade Insert S (Square) SCGT-MN-SC

SUMITOMO ELECTRIC HARDMETAL

[Specifications] - Shape: D (55° rhombus) - Groove/hole: T (with hole) - Application (breaker): Light cutting - AC1030U uses PVD coating Absotech and special tough carbide base material - High quality cutting edge The quality suppresses welding and microchipping, achieving excellent machined surface quality.

Standard Price: SGD 11.69- Days to Ship: 4 Day(s) or more -

Standard Price: SGD 23.40 Days to Ship: 4 Day(s) or more -

Standard Price: SGD 18.28- Days to Ship: 4 Day(s) or more -

Standard Price: SGD 14.56- Days to Ship: 4 Day(s) or more -

Standard Price: SGD 18.28- Days to Ship: 4 Day(s) or more -

Standard Price: SGD 10.95 Days to Ship: 4 Day(s) or more -

Standard Price: SGD 13.72 Days to Ship: 4 Day(s) or more -

Standard Price: SGD 13.72 Days to Ship: 4 Day(s) or more -

Standard Price: SGD 7.46 Days to Ship: 4 Day(s) or more -

Square-Shape With Hole, Positive 7° SCMT-LU, For Finish Cutting

SUMITOMO ELECTRIC HARDMETAL

[Features]

· Breaker with significantly improved chip control during detailed cutting.Standard Price: SGD 7.46- Days to Ship: 4 Day(s) or more -

Square-Shape With Hole, Positive 7° SCMT-MU, For Light To Medium Cutting

SUMITOMO ELECTRIC HARDMETAL

[Features]

· Low-resistance breaker with a predictable service life.Standard Price: SGD 9.06- Days to Ship: 4 Day(s) or more -

Square-Shape With Hole, Positive 7°, SCMT-SU, For Light Cutting

SUMITOMO ELECTRIC HARDMETAL

[Features]

· General-purpose breaker with excellent sharpness.Standard Price: SGD 9.06- Days to Ship: 4 Day(s) or more

| Brand |

|---|

| Product Series |

| Days to Ship |

| Shape |

| work material |

| Application |

| Available corners |

| Breaker Use |

| Rake angle |

| Nose R |

| Selfishly |

| Groove Width (For Grooving / Plunging) |

| Pitch (for Threading) |

| O.D./ I.D. (For Threading) |

| Screw Types (for threading) |

| Number of threads (for threading) |

| Brand | SANDVIK | BIG DAISHOWA SEIKI | SANDVIK | KYOCERA | SUMITOMO ELECTRIC HARDMETAL | SANDVIK | KYOCERA | KYOCERA | SANDVIK | SANDVIK | SANWA SEISAKUSYO | NGK SPARK PLUG | NGK SPARK PLUG | MISUMI | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL | SUMITOMO ELECTRIC HARDMETAL |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Product Series | T-Max P insert for turning, Square, Lathe Negative Tip, SNMA/SNMG/SNMM | CoroTurn 107 Positive Insert For Turning (Square Shaped 90°) | S Type Square 90°, Negative with Hole SNMG120408-MTM20 "Intermediate Cutting" | Square-Shape With Hole, Positive 7° SCMT-LU, For Finish Cutting | Square-Shape With Hole, Positive 7° SCMT-MU, For Light To Medium Cutting | Square-Shape With Hole, Positive 7°, SCMT-SU, For Light Cutting | |||||||||||||||||||||||||||||||||||||||

| Days to Ship | 8 Day(s) or more | 8 Day(s) or more | 10 Day(s) | 6 Day(s) or more | 4 Day(s) or more | 8 Day(s) or more | 3 Day(s) or more | 6 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 7 Day(s) or more | 15 Day(s) or more | 8 Day(s) or more | 3 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 6 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more |

| Shape | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) | S (Rectangular) |

| work material | Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Non-ferrous metal | Heat-resistant alloy, titanium alloy | Cast Iron / Heat-resistant alloy, titanium alloy / High Hardness Material | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / High Hardness Material | Cast Iron / Heat-resistant alloy, titanium alloy / High Hardness Material | Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy | Cast Iron / High Hardness Material | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy / High Hardness Material | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy | - | Cast Iron | Cast Iron / Heat-resistant alloy, titanium alloy / High Hardness Material | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy / High Hardness Material | Non-ferrous metal | Cast Iron | Cast Iron | Steel / Stainless Steel / Cast Iron / Non-ferrous metal | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy / High Hardness Material | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy / High Hardness Material | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy | Cast Iron / Non-ferrous metal | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy | Cast Iron | Cast Iron / Heat-resistant alloy, titanium alloy / High Hardness Material | Non-ferrous metal | Non-ferrous metal | Non-ferrous metal | Cast Iron / Heat-resistant alloy, titanium alloy / High Hardness Material | Cast Iron / Heat-resistant alloy, titanium alloy / High Hardness Material | High Hardness Material | Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Non-ferrous metal | Steel / Stainless Steel / Cast Iron | Steel / Stainless Steel / Cast Iron | Steel / Stainless Steel / Cast Iron / Non-ferrous metal | Steel / Stainless Steel / Cast Iron / Non-ferrous metal | Steel / Stainless Steel / Cast Iron | Steel / Stainless Steel / Cast Iron |

| Application | Outer Diameter/Inner Diameter | - | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | - | - | - | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Other | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter |

| Available corners | 4 | - | 4 | - | - | 4 | 8 | - | 4 | 4 | - | - | - | 8 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Breaker Use | Finish / Medium grinding | - | Medium grinding | - | - | - | Medium grinding | - | - | Finish / Medium grinding | - | - | - | Medium grinding | - | - | - | - | - | - | Medium grinding | - | Medium grinding | Medium grinding | - | - | - | - | - | - | - | - | Finish | - | Finish | Finish | - | Finish | Finish | - | - | Finish | Finish | - | Light Cutting |

| Rake angle | Negative | - | Pozidriv | Negative | Negative | Negative | Negative | Negative | - | Pozidriv | - | Negative | Negative | Negative | Pozidriv | Pozidriv | Pozidriv | Pozidriv | Negative | Negative | Negative | Pozidriv | Pozidriv | Pozidriv | Negative | Negative | Pozidriv | Negative / Pozidriv | Pozidriv | Negative | Pozidriv | Negative | Pozidriv | Pozidriv | Pozidriv | Pozidriv | Pozidriv | Pozidriv | Pozidriv | Pozidriv | Pozidriv | Pozidriv | Pozidriv | Pozidriv | Pozidriv |

| Nose R | 0.4 ~ Other | 0.4 ~ 0.8 | 0.4 ~ 0.8 | 0.4 ~ Other | 0.4 ~ 1.2 | 0.8 ~ Other | 0.4 ~ Other | 0.8 ~ 1.6 | 0.4 ~ 1.6 | 0.4 ~ 1.2 | - | 0.8 ~ 1.6 | 0.8 ~ 1.2 | 0.8 | 0.2 ~ Other | 0.8 ~ 1.2 | 0.8 | 0.2 ~ 0.8 | 0.8 ~ 1.6 | 0.4 ~ 1.6 | 0.4 ~ Other | 0.4 ~ 1.2 | 0.4 | 0.4 ~ 1.2 | 0.8 ~ 1.2 | 0.4 ~ 1.2 | 0.2 ~ Other | 0.2 | 0.4 ~ 0.8 | 0.4 ~ 1.2 | 0.4 ~ 0.8 | 0.4 ~ 1.2 | 0.4 | 0.2 ~ Other | 0.4 | 0.2 ~ 0.4 | 0.2 ~ Other | 0.2 ~ 0.4 | 0.4 ~ 0.8 | 0.8 | 0.4 ~ 0.8 | 0.4 ~ 0.8 | 0.4 ~ 0.8 | 0.8 | 0.4 ~ 0.8 |

| Selfishly | No-hand | - | No-hand | No-hand | - | No-hand | No-hand | No-hand | No-hand | No-hand | - | - | - | No-hand | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | Left-hand | No-hand | Right-hand | Left-hand | - | Right-hand | No-hand | No-hand | No-hand | No-hand | No-hand | No-hand | No-hand |

| Groove Width (For Grooving / Plunging) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Pitch (for Threading) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| O.D./ I.D. (For Threading) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Screw Types (for threading) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Number of threads (for threading) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

Loading...

Configure

Specification/Dimensions

-

Shape

- C (80° Diamond-Shape)

- D (55° Diamond-Shape)

- R (Circular)

- S (Rectangular)

- T (Triangle)

- V (35° Diamond-Shaped)

- W (Hexagonal Type)

- Other

-

work material

- Steel

- Stainless Steel

- Cast Iron

- Non-ferrous metal

- Heat-resistant alloy, titanium alloy

- High Hardness Material

-

Application

- Outer Diameter/Inner Diameter

- Grooving / Parting

- Threading

- Other

-

Available corners

- 1

- 2

- 3

- 4

- 6

- 8

- 9 or more

-

Breaker Use

- Finish

- Medium grinding

- Medium to deep grinding

- Heavy cutting

- Light Cutting

- Rough cutting

- Medium to coarse grinding

-

Rake angle

- Negative

- Pozidriv

-

Nose R

-

Selfishly

-

Groove Width (For Grooving / Plunging)

-

Pitch (for Threading)

-

O.D./ I.D. (For Threading)

-

Screw Types (for threading)

-

Number of threads (for threading)

Narrow search by specifying Manufacturer

-

- SUMITOMO ELECTRIC HARDMETAL (97)

- KYOCERA (51)

- SANDVIK (11)

- TUNGALOY (5)

- NGK SPARK PLUG (2)

- BIG DAISHOWA SEIKI (1)

- SANWA SEISAKUSYO (1)

- WIDIA (0)

- NOGA JAPAN (0)

- KOSHUHA (0)

- OSG (0)

CAD

-

- 2D

- 3D

How can we improve?

How can we improve?