(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla Firefox.

50,000 Stock items for Same Day Ship Out.

All Categories

Categories

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Application

Brands

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

- Please be informed of our operating hours during the Hari Raya Puasa Holidays. Click here for details.

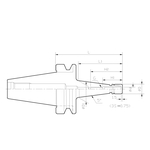

Tooling(Product Category:Main Body)

Tool holders are parts that acts as adapters when attaching cutting tools to machine tools. They allow for easy attachment/detachment of cutting tools, such as drill bits and end mills for machining, to machining centers, etc. Commonly used tool holders are collet holders (chucks), oil-hydraulic ty ...Readmore

Tool holders are parts that acts as adapters when attaching cutting tools to machine tools. They allow for easy attachment/detachment of cutting tools, such as drill bits and end mills for machining, to machining centers, etc. Commonly used tool holders are collet holders (chucks), oil-hydraulic type hydraulic holders (chucks), shrink-fit holders made using the thermal expansion of metals, etc. Tool holders are required to be of high quality in order to bring out the best performance in machine tools and cutting tools used for high-precision machining, and they play a significant role in machining precision. The combination of shanks suitable for machine tool specifications and chuck capacities for the tool bits provides an extensive variety of tool holders; selecting the ideal tool holder is a necessity. ▲ Close

Search by specifying the lower class category

Shrink Fit Holders

Shrink Fit Holders Hydro Chucks

Hydro Chucks Milling Chucks

Milling Chucks Milling Cutter Arbors

Milling Cutter Arbors Collet Holders

Collet Holders Drill Chucks

Drill Chucks Tap Holders

Tap Holders Collets

Collets Tooling-Related Equipment

Tooling-Related Equipment Presetters

Presetters Products for Coolants

Products for Coolants

| Days to Ship |

|

|---|

-

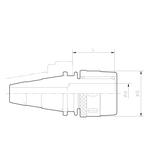

Mega New Baby Chuck (Two-Plane Restraint, For High-Speed Rotation)

BIG DAISHOWA SEIKI

[Features]

· In addition to high accuracy and general utility, it is also capable of high-speed machining.

· New baby chuck high-speed rotation series with proven results.Standard Price: SGD 424.74- Days to Ship: 8 Day(s) or more -

Keyless Drill Chuck Precision Grade (Silver)

YUKIWA SEIKO

Keyless type drill chuck allowing drill attachment/detachment with manual rotation alone.

[Features]

· The world's No. 1 accuracy: The ultra-precision class is finished to unparalleled precision by assembling world-class technologies.

· It demonstrates fully sufficient power for high precision machining, such as tooling of machining centers and jig borers, etc.

· The test method for the measurement position conforms to JIS B 4634.

· Maximum accuracy: Precision class maintains accuracy over a long period of time, with the highest accuracy in the world after . Standard Price: SGD 188.01- Days to Ship: 4 Day(s) or more -

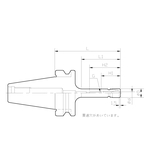

Mega Double Power Chuck (Standard Type)

BIG DAISHOWA SEIKI

[Features]

Nut and body in full contact.

· "Big Plus specifications" provide double the efficiency.

· High rigidity approaching the integration with the spindle.Standard Price: SGD 577.32- Days to Ship: 10 Day(s) -

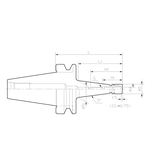

New High Power Milling Chuck (BT Shank)

BIG DAISHOWA SEIKI

[Features]

·BIG's unique slitting mechanism supports high power and high precision end mill processing from heavy cuts to fine cuts.Standard Price: SGD 464.30- Days to Ship: 8 Day(s) or more -

NT TOOL

A handy hydrochuck that can be used as a collet holder. Ideal for high-precision machining

Standard Price: SGD 593.93- Days to Ship: 8 Day(s) -

Deburring Tool Holder Barriquan®

SUGINO MACHINE

[Features]

·Uniform removal of burrs by profiling

·Suitable for deburring complex shapes

·Can be attached to various processing machines

·Versatility for various tools

·The 10 mm expansion/contraction function follows variations in workpiece dimensions and shapes, enabling uniform deburring with a simple program.

·The spring load for expansion and contraction can be adjusted while attached to the processing machine, and settings can be made quickly according to the size of the burr and the cutter.

[Applications]

·For deburring castings and die-cast products

·For removing burrs from press-molded productsStandard Price: SGD 714.24 Days to Ship: 7 Day(s) -

Quick Change Holder Milling Chuck

BIG DAISHOWA SEIKI

·Quick tool change increases the operating rate of the milling machine. · It has a heavy-duty clamp structure that prevents the clamping nut from loosening even with the vibration of heavy cutting. · It has a tool fall prevention mechanism, so the clamping nut will not fall off even if it is loosened

Standard Price: SGD 643.42- Days to Ship: 10 Day(s) -

Chuck Holder for Drill Tappers

BIG DAISHOWA SEIKI

[Features]

The holder can be attached and removed quickly.

(See manufacturer catalog for details)Standard Price: SGD 79.29- Days to Ship: 8 Day(s) -

Morse Taper Holder A Type (Tang Type)

BIG DAISHOWA SEIKI

[Features]·Stable runout accuracy is achieved through high-precision inner diameter machining. ·Big Plus (BBT shank) tools can be used on Big Plus main shanks and machine with conventional BT main shanks.

Standard Price: SGD 146.92- Days to Ship: 10 Day(s) -

YUKIWA SEIKO

[Features]

· The quality of the drill chuck is determined by factors such as core runout accuracy, drill grasping force and accuracy sustainability [durability].

· YUKIWA brand drill chucks are manufactured according to standards exceeding the JIS B 4634 machine tool drill chuck standard, boasting high precision, high quality, and outstanding durability widely recognized around the world.

· Runout accuracy: Accuracy equal to or greater than JIS standard runout accuracy is guaranteed.

· Gripping force: Maintains stable and strong gripping force through excellent technology and strict quality control.

· Endurance: With an appropriate thermal treatment, it has excellent wear resistance and retains precision.

· Jacobs Taper Hole: Since the taper hole is given a grinding finish, it has an extremely large taper range and will not slip.Standard Price: SGD 52.10- Days to Ship: 4 Day(s) or more -

HSK Shank New Baby Chuck (A Type)

BIG DAISHOWA SEIKI

[Features]

· Robust series including short to long sizes. Provides strong support for high precision machining.

· The collet enables increased efficiency due to its 1-micron runout accuracy at the nose.

· Optimal as basic holder for a variety of processes including drilling, reaming and end milling.Standard Price: SGD 389.45- Days to Ship: 11 Day(s) or more -

HSK Shank New High-Power Milling Chuck S Type (A Type)

BIG DAISHOWA SEIKI

[Features]

· BIG's original slit mechanism provides high-power and high-precision support for everything from heavy cutting to fine cutting for end mill processing.Standard Price: SGD 578.72- Days to Ship: 10 Day(s) -

MANYO TOOLS

[Features]

·A wide variety of types are available for various cutters.

·Minimum order quantity: 1 pc.

·For SANDVIK and SECO face milling machine. A wide variety of types are available for various cutters.Standard Price: SGD 248.22 Days to Ship: 8 Day(s) or more -

BIG DAISHOWA SEIKI

[Features]

· A face mill arbor for cutters that support through-tool cooling, reliably supplying coolant and air to the cutting edge.Standard Price: SGD 274.98- Days to Ship: 10 Day(s) or more -

BIG DAISHOWA SEIKI

[Features]

· Face mill Arbor type A suitable for JIS B4113 (1970) face millingStandard Price: SGD 201.41- Days to Ship: 10 Day(s) -

Mega Synchro Tapping Holder (BBT Shank)

BIG DAISHOWA SEIKI

[Features]

· Thrust load caused by synchronization error is reduced to 1/10 to improve thread precision and tap longevity.

· In addition to various tap sizes, the long tap holder is standardized.Standard Price: SGD 289.76- Days to Ship: 8 Day(s) -

Mega Micro Chuck (Straight Type)

BIG DAISHOWA SEIKI

[Features]

· Supports ultra-small diameter end mill processing, this ultra-small design is the world's smallest nut with a ø10 outer diameter.

· A slim, high-speed rotation holder taking workpiece and jig interference into consideration.Standard Price: SGD 430.61- Days to Ship: 10 Day(s) -

Mega Micro Chuck (High Rigidity Type)

BIG DAISHOWA SEIKI

[Features]

· Supports ultra small diameter end mill processing.

· Ultra-slim design with world's smallest 10 nut outer diameter.

· Slim, high speed rotation holder designed to prevent interference with workpiece and jig.Standard Price: SGD 443.80- Days to Ship: 10 Day(s) -

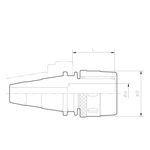

New Baby Chuck (Collet Chuck System)

BIG DAISHOWA SEIKI

[Features]

· Basic holder providing firm support for high precision machining for tools including drill machines, reamers and end mills.

· The collet enables increased efficiency due to its 1-micron runout accuracy at the nose.

· Robust series including short to long sizes.Standard Price: SGD 308.94- Days to Ship: 8 Day(s) or more -

15T/S20T/BT30/BT35 New Drill Mill Chuck

YUKIWA SEIKO

High rigidity, high precision drill mill chuck compatible with high pressure coolants

Standard Price: SGD 390.77- Days to Ship: 8 Day(s) or more -

Milling Chuck (Micron Chuck) BT Series

SHOWA TOOL

High speed chuck that achieves high rigidity and high precision.

[Features]

· Only micron chucks can guarantee such minimal runout.

· Provides both high rigidity and high precision. Achieves strong and intricate machining.Standard Price: SGD 456.94- Days to Ship: 6 Day(s) or more -

High Accuracy Collet Holder HDC / A

NT TOOL

Suitable for drilling, reaming and finishing end mill machining.

·Spindle/shank shape: BT

·Spindle/shank type: BT

·Availability of CAD Data: 2DStandard Price: SGD 391.18- Days to Ship: 6 Day(s) or more -

BIG DAISHOWA SEIKI

[Features]

·For tapping.

·Usable with drill tapping tool DT series.

·You can smoothly exchange a tap holder.Standard Price: SGD 104.59- Days to Ship: 8 Day(s) or more -

BIG DAISHOWA SEIKI

[Features]

· Handles interference issues flexibly when combined with the BIG NEW Hi- POWER MILLING CHUCK.

· It enables easy tool layout with a horizontal machining center where workpieces and jigs often interfere.Standard Price: SGD 170.85- Days to Ship: 11 Day(s) -

Face Mill Arbor H Type BT30/BT40/BT50

BIG DAISHOWA SEIKI

[Features]

· A face mill arbor for cutters that support through-tool cooling, reliably supplying coolant and air to the cutting edge.Standard Price: SGD 234.11- Days to Ship: 10 Day(s) -

TAKURA KOGU

[Features]

・ Vertical sleeve

·G (drawing thread): 1/2W or M12

·Outside taper: NT30

·T (mm): 12Standard Price: SGD 265.93 Days to Ship: 6 Day(s) or more -

BIG DAISHOWA SEIKI

[Features]

Center through type.

A side lock drill holder.

·Dual contact

·Spindle/shank type: BBT/BT

·Spindle/shank number: 40,50

·Grip diameter: 16 mm / 20 mm / 25 mm / 32 mm / 40 mm / 50 mm

·Coolant supply system, etc.: center through

·Holder length: 75 mm / 80 mm / 90 mm / 105 mm / 135 mm / 165 mm / 200 mm / 250 mm / 270 mmStandard Price: SGD 225.94- Days to Ship: 8 Day(s) or more -

New High Power Milling Chuck (BBT Shank, Small Type)

BIG DAISHOWA SEIKI

[Features]

· The BIG original slit mechanism supports high power and high-precision endmilling from heavy cuts to fine cuts.Standard Price: SGD 483.42- Days to Ship: 10 Day(s) -

Mega Synchro Tapping Holder (Large Diameter Tap for MGT36)

BIG DAISHOWA SEIKI

[Features]

· Compensates for axial misalignment due to synchronization error, and dramatically reduces load during machining.

· Structure smoothly complies even with excessive cutting torque of large diameter taps.Standard Price: SGD 910.36 Days to Ship: 10 Day(s) -

YUKIWA SEIKO

The ultimate tool holder. Satisfies all the user's needs with high accuracy, high rigidity, high gripping force, high balance, and safety

Standard Price: SGD 393.49- Days to Ship: 8 Day(s) or more -

YUKIWA SEIKO

The ultimate tool holder. Satisfies all the user's needs with high accuracy, high rigidity, high gripping force, high balance, and safety

Standard Price: SGD 391.14- Days to Ship: 8 Day(s) or more -

YUKIWA SEIKO

The ultimate tool holder. Satisfies all the user's needs with high accuracy, high rigidity, high gripping force, high balance, and safety

Standard Price: SGD 435.08- Days to Ship: 14 Day(s) -

BT40/BT50 New Drill Mill Chuck

YUKIWA SEIKO

High rigidity, high precision drill mill chuck compatible with high pressure coolants

Standard Price: SGD 441.68- Days to Ship: 8 Day(s) or more -

Keyless Drill Chuck Ultra Precision Grade (Gold)

YUKIWA SEIKO

[Features]

· The world's No. 1 accuracy: The ultra-precision class is finished to unparalleled precision by assembling world-class technologies.

· Runout accuracy (total indicator reading, TIR): 30 μ or less.

· Used test bar: Maximum gripping diameter and radius.

· It demonstrates fully sufficient power for high precision machining, such as tooling of machining centers and jig borers, etc.

· Handle not required: Because a large number of thrust balls are used on the inside, no tools such as handles are required, meaning that attachment and removal of cutting tools can be performed easily with the fingertips.Standard Price: SGD 245.70- Days to Ship: 8 Day(s) or more -

KOBAYASHI IRON WORKS

Split jaw type with hard and soft jaws

[Features]

·Ideal for machining, milling machines, drill presses, slotters, gear cutting machines, split tables, etc.

·The handle insertion angle is 30°, so you can operate the handle while it is attached to the table, allowing you to work smoothly.

·The body is thin, so it is possible to process workpieces that were previously impossible to mount. In addition, the thin design allows the center of gravity of the workpiece to be fixed at a lower position relative to the table, allowing for more stable processing.

·The body flange has a U-hole, and can be easily fixed with a T-nut and bolt using the T-slot on the table.

·A unique tapered seal structure is used at the joint between the body and scroll to eliminate seizure caused by the intrusion of dirt and reduce the frequency of lubrication.Standard Price: SGD 2,460.43- Days to Ship: 8 Day(s) or more -

VESSEL

A drill chuck that can be used for various purposes by attaching a drill or a bit to the tip.

[Features]

· For air/electric screwdrivers.

· Outstanding gripping force and high precision.

· Shaft features outstanding durability.

· Key type: Attached key for attaching and detaching tool tips.

· Hybrid-type: Dual type with or without key.

[Applications]

· For buildings, facilities, etc.Standard Price: SGD 38.49- Days to Ship: 8 Day(s) -

Standard Price: SGD 63.41- Days to Ship: 4 Day(s) or more -

NT Shank New High Power Milling Chuck

BIG DAISHOWA SEIKI

[Features]

· Features thick walls and special slits to help resolve chatter and slips when endmilling.

· It achieves the three goals of rigidity, precision, and graspability.Standard Price: SGD 591.13- Days to Ship: 8 Day(s) or more -

BIG DAISHOWA SEIKI

[Features]·Achieves high-precision machining in combination with Mega New Baby

Standard Price: SGD 154.78- Days to Ship: 10 Day(s) -

Straight shank new Drill Mill chuck for use with side lock

YUKIWA SEIKO

High rigidity, high precision drill mill chuck compatible with high pressure coolants

Standard Price: SGD 171.86- Days to Ship: 8 Day(s) or more -

Straight shank new Drill Mill chuck for use with Milling Chuck

YUKIWA SEIKO

High rigidity, high precision drill mill chuck compatible with high pressure coolants

Standard Price: SGD 165.71- Days to Ship: 8 Day(s) or more -

Jacobs Taper Shank New Drill Mill Chuck

YUKIWA SEIKO

High rigidity, high precision drill mill chuck compatible with high pressure coolants

Standard Price: SGD 210.70- Days to Ship: 4 Day(s) or more -

Standard Price: SGD 171.64- Days to Ship: 8 Day(s) or more -

KATO MFG

[Features]

· Short body type that can be used in most machines

· Expansion device for absorbing feed errors

· Short type ideal for use in tight work spacesStandard Price: SGD 693.50 Days to Ship: 12 Day(s) or more -

Manual Locking System YHL-C For HSK Holder

YUKIWA SEIKO

[Features]

· Clamping and unclamping can be performed with a 120° rotation operation, enabling single-action holder replacement.Standard Price: SGD 2,529.53 Days to Ship: 14 Day(s)

| Brand |

|---|

| Product Series |

| Days to Ship |

| Spindle types |

| HSK type |

| Tool Type |

| Retainable blade diameter(mm) |

| Product Category |

| Applicable Manufacturing Machinery (main unit) |

| Chuck Type |

| Holder Length L(mm) |

| Maximum Allowable Rotational Speed(min-1) |

| Coolant System |

| Nozzle Type |

| Brand | BIG DAISHOWA SEIKI | YUKIWA SEIKO | BIG DAISHOWA SEIKI | BIG DAISHOWA SEIKI | NT TOOL | SUGINO MACHINE | BIG DAISHOWA SEIKI | BIG DAISHOWA SEIKI | BIG DAISHOWA SEIKI | YUKIWA SEIKO | BIG DAISHOWA SEIKI | BIG DAISHOWA SEIKI | MANYO TOOLS | BIG DAISHOWA SEIKI | BIG DAISHOWA SEIKI | BIG DAISHOWA SEIKI | BIG DAISHOWA SEIKI | BIG DAISHOWA SEIKI | BIG DAISHOWA SEIKI | YUKIWA SEIKO | SHOWA TOOL | NT TOOL | BIG DAISHOWA SEIKI | BIG DAISHOWA SEIKI | BIG DAISHOWA SEIKI | TAKURA KOGU | BIG DAISHOWA SEIKI | BIG DAISHOWA SEIKI | BIG DAISHOWA SEIKI | YUKIWA SEIKO | YUKIWA SEIKO | YUKIWA SEIKO | YUKIWA SEIKO | YUKIWA SEIKO | KOBAYASHI IRON WORKS | VESSEL | YUKIWA SEIKO | BIG DAISHOWA SEIKI | BIG DAISHOWA SEIKI | YUKIWA SEIKO | YUKIWA SEIKO | YUKIWA SEIKO | YUKIWA SEIKO | KATO MFG | YUKIWA SEIKO |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Product Series | Mega New Baby Chuck (Two-Plane Restraint, For High-Speed Rotation) | Straight shank new Drill Mill chuck for use with Milling Chuck | |||||||||||||||||||||||||||||||||||||||||||

| Days to Ship | 8 Day(s) or more | 4 Day(s) or more | 10 Day(s) | 8 Day(s) or more | 8 Day(s) | 7 Day(s) | 10 Day(s) | 8 Day(s) | 10 Day(s) | 4 Day(s) or more | 11 Day(s) or more | 10 Day(s) | 8 Day(s) or more | 10 Day(s) or more | 10 Day(s) | 8 Day(s) | 10 Day(s) | 10 Day(s) | 8 Day(s) or more | 8 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 8 Day(s) or more | 11 Day(s) | 10 Day(s) | 6 Day(s) or more | 8 Day(s) or more | 10 Day(s) | 10 Day(s) | 8 Day(s) or more | 8 Day(s) or more | 14 Day(s) | 8 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 8 Day(s) | 4 Day(s) or more | 8 Day(s) or more | 10 Day(s) | 8 Day(s) or more | 8 Day(s) or more | 4 Day(s) or more | 8 Day(s) or more | 12 Day(s) or more | 14 Day(s) |

| Spindle types | BT30 / BT40 / BT50 | - | BT30 / BT40 / BT50 | BT30 / BT40 / BT50 | BT30 / BT40 | - | - | - | BT30 / BT40 / BT50 | - | HSK-A | HSK-A | BT30 | BT40 / BT50 | BT30 / BT50 | BT30 / BT40 / BT50 | BT30 / BT40 | BT30 / BT40 | BT30 / BT40 / BT50 | BT30 | BT40 | BT30 / BT40 / BT50 | - | - | BT30 / BT40 / BT50 | - | BT30 / BT40 / BT50 | BT30 / BT40 / BT50 | BT50 | - | BT30 | BT40 | BT40 / BT50 | - | - | - | - | - | - | - | - | - | - | - | - |

| HSK type | - | - | - | - | - | - | - | - | - | - | 63 ~ 100 | 63 ~ 100 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 63 |

| Tool Type | - | - | - | end mill | end mill / drill / Reamer | - | end mill | drill | - | - | end mill / drill / Reamer | end mill | Facemill | Facemill | - | Tap | - | - | end mill / drill / Reamer | - | end mill / drill / Reamer / Tap | end mill / drill / Reamer | Tap | - | Facemill | - | - | end mill | Tap | - | - | - | - | - | - | drill | drill | end mill | - | - | - | - | - | Tap | - |

| Retainable blade diameter(mm) | 0.25~ 6 ~ 2.5 ~20 | 0.3~3 ~ 3 to 16 | 16 ~ 50 | - | 6 ~ 32 | - | - | - | - | - | - | - | - | - | - | - | 0.45~4.05 ~ 2.95 to 8.05 | 0.45~3.25 ~ 2.95~8.05 | - | 0.5~5.0 ~ 5.0~25.0 | 32 | 0.5~7 ~ 3.5~22 | - | 0.25~ 6 ~ 2.5 ~20 | - | - | - | - | - | 1.0~6.0 ~ 3.0~16.0 | 1.0~6.0 ~ 3.0~20.0 | 1.0~6.0 ~ 16.0~32.0 | 0.5~7.0 ~ 5.0~32.0 | 0.3~3 ~ 3 to 16 | - | 0.8~6.5 ~ 1.5~13 | - | - | 0.45~3.25 ~ 2.95~8.05 | 0.5~7.0 ~ 5.0~25.0 | 0.5~5.0 ~ 5.0~25.0 | 0.5~5.0 ~ 0.5~13.0 | 0.5~7.0 ~ 2.5~20.0 | M3 to M16 | - |

| Product Category | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body |

| Applicable Manufacturing Machinery (main unit) | Machining Centers | - | Machining Centers | Machining Centers | Machining Centers | Machining Centers | Generic Machine | Generic Machine | Machining Centers | Generic Machine | - | - | Machining Centers | Generic Machine | Generic Machine | Machining Centers | Machining Centers | Machining Centers | Machining Centers | Machining Centers | Machining Centers | Machining Centers | Generic Machine | Machining Centers | Generic Machine | Generic Machine | Machining Centers | Machining Centers | Machining Centers | Machining Centers | Machining Centers | Machining Centers | Machining Centers | - | Generic Machine | - | Generic Machine | Generic Machine | Machining Centers | Generic Machine | Generic Machine | Generic Machine | Machining Centers | - | Machining Centers |

| Chuck Type | - | - | - | - | Hydro | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | Side lock | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Holder Length L(mm) | 60 ~ 300 | 44 ~ 96 | 60 ~ 200 | - | 45 ~ 150 | - | 54.4 ~ 76.7 | - | 45 ~ 210 | - | - | - | - | 45 ~ 350 | 45 ~ 350 | 100/140/170 ~ 145/195/225 | 60 ~ 105 | 45 ~ 150 | 45 ~ 300 | 35 ~ 120 | 105 ~ 135 | 90 ~ 255 | - | - | 35 ~ 200 | - | 75 ~ 250 | 70 ~ 300 | 190 | 34 ~ 75 | 45 ~ 105 | 60 ~ 200 | 60 ~ 165 | 44 ~ 96 | - | - | - | 60 ~ 85 | - | - | - | - | - | 93 | - |

| Maximum Allowable Rotational Speed(min-1) | 20000 ~ 50000 | - | 30000 | - | - | - | - | - | - | - | - | - | - | - | - | - | 50000 | 50000 | - | - | 10000 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Coolant System | - | - | Center Through (Blade Through) | Center Through (Blade Through) | - | - | - | - | - | - | Center Through (Blade Through) | Center Through (Blade Through) | - | Center Through (Blade Through) | - | Center Through (Blade Through) | - | - | Center Through (Blade Through) | - | - | - | - | - | Center Through (Blade Through) | - | Center Through (Blade Through) | Center Through (Blade Through) | Center Through (Blade Through) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Nozzle Type | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

Loading...

Configure

Specification/Dimensions

-

Spindle types

- BT30

- BT40

- BT50

- HSK-A

- HSK-E

- ST20

- ST32

-

HSK type

-

Tool Type

- end mill

- drill

- Reamer

- Facemill

- Tap

-

Retainable blade diameter(mm)

- 0.25~0.50

- 0.25~ 6

- 0.3~3

- 0.4–0.5

- 0.45 ~0.55

- 0.45~3.25

- 0.45~4.05

- 0.45~6.05

- 0.5 to 0.75

- 0.50 to 0.75

- 0.5~5.0

- 0.5~ 6

- 0.5~6.5

- 0.5~7

- 0.5~7.0

- 0.5 ~ 8

- 0.5~8

- 0.5~ 8

- 0.5–10

- 0.5~10.0

- 0.5~13

- 0.5~13.0

- 0.5~16.0

- 0.55 ~0.65

- 0.6~0.7

- 0.65 ~0.75

- 0.7~0.8

- 0.75 ~0.85

- 0.75~1.0

- 0.75~1.00

- 0.8~0.9

- 0.8~6.5

- 0.85 ~0.95

- 0.9 to 1.0

- 0.95 ~1.05

- 1

- 1.0~0.5

- 1.0~1.1

- 1.0~1.25

- 1.00~1.25

- 1.0~6.0

- 1.0~8.0

- 1.0~10

- 1 to 13

- 1.05 ~1.15

- 1.15 ~1.25

- 1.2~1.3

- 1.25 ~1.35

- 1.25~1.5

- 1.25~1.50

- 1.35 ~1.45

- 1.4 to 1.5

- 1.45 ~1.55

- 1.5

- 1.5-13

- 1.5~1.0

- 1.5–1.6

- 1.50~1.75

- 1.5~1.75

- 1.5 to 10

- 1.5 ~10

- 1.5~13

- 1.5~20.0

- 1.55 ~1.65

- 1.6 to 1.7

- 1.65 ~1.75

- 1.7 to 1.8

- 1.75 ~1.85

- 1.75~2.0

- 1.75~2.00

- 1.8~1.9

- 1.85 ~1.95

- 1.9~2.0

- 1.95 ~2.05

- 2

- 2.0~1.5

- 2.0~2.1

- 2.0~2.25

- 2.00~2.25

- 2.0~10.0

- 2.05 ~2.15

- 2.1~2.2

- 2.15 ~2.25

- 2.2~2.3

- 2.25 ~2.35

- 2.25~2.5

- 2.25~2.50

- 2.3~2.4

- 2.35 ~2.45

- 2.4~2.5

- 2.45 ~2.55

- 2.5

- 2.5 to 2.0

- 2.5~2.6

- 2.5~2.75

- 2.50~2.75

- 2.5–3.0

- 2.5~9

- 2.5~12

- 2.5 to 13

- 2.5 ~13

- 2.5~13

- 2.5 to 16

- 2.5 ~16

- 2.5~16.0

- 2.5 to 20

- 2.5 ~20

- 2.5~20.0

- 2.5~20

- 2.55 ~2.65

- 2.6~2.7

- 2.65 ~2.75

- 2.675~3.175

- 2.7~2.8

- 2.75 ~2.85

- 2.75~3.0

- 2.75~3.00

- 2.75~3.25

- 2.8~2.9

- 2.85 ~2.95

- 2.9~3.0

- 2.925~3.175

- 2.95 ~3.05

- 2.95~3.05

- 2.95 to 8.05

- 2.95~8.05

- 3

- 3.0~2.5

- 3.0~3.1

- 3.00~3.25

- 3~3.5

- 3.0–3.5

- 3–4

- 3–6

- 3~ 6

- 3~ 8

- 3–10

- 3 to 12

- 3.0~12.5

- 3 to 16

- 3.0~16.0

- M3 to M16

- 3.0~20.0

- 3.05 ~3.15

- 3.05~3.15

- 3.1~3.2

- 3.125~3.225

- 3.15 ~3.25

- 3.15~3.25

- 3.175

- 3.2~3.3

- 3.2~3.4

- 3.25 ~3.35

- 3.25~3.35

- 3.25~3.50

- 3.25~3.75

- 3.3–3.4

- 3.35 ~3.45

- 3.35~3.45

- 3.4~3.5

- 3.40~3.50

- 3.4~3.6

- 3.45 ~3.55

- 3.45~3.55

- 3.5~3.0

- 3.5~3.6

- 3.50~3.75

- 3.5~4.0

- 3.5~16

- 3.5~20.0

- 3.5~22

- 3.55 ~3.65

- 3.55~3.65

- 3.6~3.8

- 3.65 ~3.75

- 3.65~3.75

- 3.7~3.8

- 3.75 ~3.85

- 3.75~3.85

- 3.75~4.00

- 3.75~4.25

- 3.75~ 4.25

- 3.8~3.9

- 3.85 ~3.95

- 3.85~3.95

- 3.9~4.0

- 3.90~4.00

- 3.95 ~4.05

- 3.95~4.05

- 4

- 4.0~3.5

- 4.0~4.1

- 4.0 to 4.2

- 4.00~4.25

- 4~4.5

- 4.0–4.5

- 4–5

- 4.05 ~4.15

- 4.05~4.15

- 4.1~4.2

- 4.15 ~4.25

- 4.15~4.25

- 4.2~4.3

- 4.2~4.4

- 4.25 ~4.35

- 4.25~4.35

- 4.25~4.50

- 4.25~4.75

- 4.25~ 4.75

- 4.3~4.4

- 4.35 ~4.45

- 4.35~4.45

- 4.4~4.5

- 4.40~4.50

- 4.4~4.6

- 4.45 ~4.55

- 4.45~4.55

- 4.5~4.0

- 4.5~4.6

- 4.50~4.75

- 4.5–5.0

- 4.55 ~4.65

- 4.55~4.65

- 4.6~4.7

- 4.6~4.8

- 4.65 ~4.75

- 4.65~4.75

- 4.7~4.8

- 4.7125~4.8125

- 4.75 ~4.85

- 4.75~4.85

- 4.75~5.00

- 4.75 to 5.25

- 4.8~4.9

- 4.85 ~4.95

- 4.85~4.95

- 4.9~5.0

- 4.90~5.00

- 4.95 ~5.05

- 4.95~5.05

- 5

- 5.0~4.0

- 5.0~4.5

- 5.00~5.25

- 5.0~5.5

- 5~5.5

- 5–6

- 5.0~25.0

- 5.0~32.0

- 5.05 ~5.15

- 5.05~5.15

- 5.1~5.2

- 5.15 ~5.25

- 5.15~5.25

- 5.2~5.3

- 5.25 ~5.35

- 5.25~5.35

- 5.25~5.50

- 5.25~5.75

- 5.3~5.4

- 5.35 ~5.45

- 5.35~5.45

- 5.4~5.5

- 5.40~5.50

- 5.45 ~5.55

- 5.45~5.55

- 5.5

- 5.5~5.0

- 5.5~5.6

- 5.50~5.75

- 5.5 to 6.0

- 5.5–6.0

- 5.55 ~5.65

- 5.55~5.65

- 5.6~5.7

- 5.65 ~5.75

- 5.65~5.75

- 5.7~5.8

- 5.75 ~5.85

- 5.75~5.85

- 5.75~6.00

- 5.8~5.9

- 5.85 ~5.95

- 5.85~5.95

- 5.9~6.0

- 5.90~6.00

- 5.95 ~6.05

- 5.95~6.05

- 6

- 6.0~5.0

- 6.0~5.5

- 6 to 6.5

- 6.0–6.5

- 6–7

- 6.0~25.0

- 6.05~6.15

- 6.15~6.25

- 6.2

- 6.25~6.35

- 6.35~6.45

- 6.4~6.5

- 6.45~6.55

- 6.5~6.0

- 6.5 to 7.0

- 6.55~6.65

- 6.65~6.75

- 6.75~6.85

- 6.85~6.95

- 6.9~7.0

- 6.95~7.05

- 7

- 7.0~6.0

- 7.0~6.5

- 7.0~7.5

- 7~7.5

- 7–8

- 7.05~7.15

- 7.15~7.25

- 7.25~7.35

- 7.35~7.45

- 7.4~7.5

- 7.45~7.55

- 7.5~8.0

- 7.55~7.65

- 7.65~7.75

- 7.75~7.85

- 7.85~7.95

- 7.9~8.0

- 7.95~8.05

- 8

- 8.0~7.0

- 8~8.5

- 8.0~8.5

- 8–9

- 8.4~8.5

- 8.5

- 8.5~9.0

- 8.9~9.0

- 9

- 9.0~8.0

- 9.0~9.5

- 9~9.5

- 9–10

- 9.4~9.5

- 9.5 to 10.0

- 9.9~10.0

- 10

- 10.0~9.0

- 10.0 ~10.5

- 10.0~10.5

- 10~10.5

- 10~11

- 10.4~10.5

- 10.5

- 10.5~11.0

- 10.9~11.0

- 11

- 11.0~10.0

- 11.0~11.5

- 11~11.5

- 11~12

- 11.4~11.5

- 11.5~12.0

- 11.9~12.0

- 12

- 12.0~11.0

- 12.0~12.5

- 12~12.5

- 12~13

- 12.4~12.5

- 12.5

- 12.5~13.0

- 12.9~13.0

- 13

- 13.0~12.0

- 13.0~13.5

- 13~14

- 13.4~13.5

- 13.5~14.0

- 13.9~14.0

- 14

- 14.0~13.0

- 14.0~14.5

- 14~15

- 14.4~14.5

- 14.5~15.0

- 14.9~15.0

- 15

- 15.0~14.0

- 15.0~15.5

- 15~16

- 15.4~15.5

- 15.5~16.0

- 15.9~16.0

- 16

- 16.0~15.0

- 16.0~16.5

- 16~17

- 16.0~32.0

- 16.4~16.5

- 16.5

- 16.5~17.0

- 16.9~17.0

- 17.0~16.0

- 17.0~17.5

- 17~18

- 17.4~17.5

- 17.5~18.0

- 17.9~18.0

- 18

- 18.0~17.0

- 18.0~18.5

- 18~19

- 18.4~18.5

- 18.5~19.0

- 18.9~19.0

- 19

- 19.0~18.0

- 19.0~19.5

- 19~20

- 19.4~19.5

- 19.5~20.0

- 19.9~20.0

- 20

- 20.0~19.0

- 21

- 21.0~20.0

- 22

- 22.0~21.0

- 23

- 23.0~22.0

- 24

- 24.0~23.0

- 25

- 25.0~24.0

- 28.0~27.0

- 30.0~29.0

- 32

- 32.0~31.0

- M36

- 38

- 39

- 40

- 42

- 50

- 50.8

-

Product Category

- Main Body

- Attachments/Accessories

- Heating and Cooling Equipment

- Measuring equipment

-

Applicable Manufacturing Machinery (main unit)

- Machining Centers

- Generic Machine

- NC Lathe

-

Chuck Type

- Straight collet

- Shrink fit

- Hydro

- Side lock

-

Holder Length L(mm)

- 10.5

- 15.5

- 16

- 16.5

- 19.5

- 20

- 24.5

- 25

- 26.5

- 29

- 30

- 33

- 34

- 35

- 35.5

- 37

- 38.3

- 39

- 40

- 43

- 44

- 44.1

- 45

- 47

- 48

- 50

- 52

- 53

- 54

- 54.4

- 54.6

- 55

- 55.5

- 60

- 62

- 62.5

- 65

- 67.5

- 68.5

- 70

- 73

- 74

- 75

- 76.7

- 77

- 80

- 81

- 84.5

- 85

- 90

- 90.5

- 91

- 92

- 93

- 94.5

- 95

- 95/135/165

- 96

- 97.5

- 100

- 100/140/170

- 105

- 105/145/175

- 107

- 107.5

- 109.5

- 110

- 115

- 120

- 120/160/190

- 121

- 122

- 125

- 125/175/205

- 130

- 130/180/210

- 131.5

- 132

- 135

- 137

- 137.5

- 140

- 140/190/220

- 145/195/225

- 150

- 155

- 162.5

- 164.5

- 165

- 167

- 167.5

- 169

- 176.5

- 180

- 180.5

- 182.5

- 185

- 186.5

- 190

- 193.5

- 195

- 200

- 202.5

- 210

- 220

- 225

- 240

- 250

- 255

- 300

- 350

-

Maximum Allowable Rotational Speed(min-1)

-

Coolant System

- Center Through (Blade Through)

- Gap Through

-

Nozzle Type

- End Cap

Narrow search by specifying Manufacturer

-

- YUKIWA SEIKO (47)

- BIG DAISHOWA SEIKI (46)

- KATO MFG (6)

- TAKURA KOGU (6)

- MANYO TOOLS (5)

- VESSEL (5)

- SHOWA TOOL (4)

- NT TOOL (3)

- KOBAYASHI IRON WORKS (1)

- MINITOR (1)

- NIIGATA SEIKI (SK) (1)

- SUGINO MACHINE (1)

- KYORITSU SEIKI (0)

- NIKKENKOSAKU (0)

- NAKANISHI (0)

- DREMEL (0)

- MARVEL (0)

- NEW STRONG (0)

- TRUSCO NAKAYAMA (0)

- FUJI TOOL (0)

- MITSUTOMO (0)

- TSCHORN (0)

- TOHIN SHOJI (0)

- SHINWASOKUTEI (0)

- VERTEX (0)

- ALBRECHT (0)

- GIGA SELECTION (0)

- NABEYA (0)

- OSG (0)

- THE CUT (0)

- ESCO (0)

- NOGA JAPAN (0)

- NIKKI TRADING (0)

- SANDVIK (0)

- KASAHARA (0)

- FUSOSEIKI (0)

- SUMITOMO ELECTRIC HARDMETAL (0)

CAD

-

- 2D

- 3D

How can we improve?

How can we improve?