(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla Firefox.

50,000 Stock items for Same Day Ship Out.

All Categories

Categories

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Application

Brands

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 9:00 19/1/2025 to 6:00 (SGT) 20/1/2025. We apologize for the inconvenience.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Tooling(Page6)

Search by specifying the lower class category

Shrink Fit Holders

Shrink Fit Holders Hydro Chucks

Hydro Chucks Milling Chucks

Milling Chucks Milling Cutter Arbors

Milling Cutter Arbors Collet Holders

Collet Holders Drill Chucks

Drill Chucks Tap Holders

Tap Holders Collets

Collets Tooling-Related Equipment

Tooling-Related Equipment Presetters

Presetters Products for Coolants

Products for Coolants

| Days to Ship |

|

|---|

-

MANYO TOOLS

[Features]

·Usable with MTC ultra long slim chuck holders.

·Standard drills can be used for deep hole drilling, making it possible to reduce costs.

·Outstanding runout of 5 µm or less.

·Easy attachment and removal of blades, without need for expensive dedicated equipment.

Simple structure improves workability.

·End mill types are suitable for mold finishing.Standard Price: SGD 124.58 Days to Ship: 18 Day(s) or more -

MTC Extra-Long Slim Collet Chuck Holder

MANYO TOOLS

A shell diameter slim chuck specification, with consideration for interference. Costs can be reduced since standard drills can be used for drilling deep holes. Excellent runout accuracy of 5 μm or less. Easy blade attachment/detachment without the need for any expensive dedicated equipment. Simple structure that improves the workability

Standard Price: SGD 271.30 Days to Ship: 18 Day(s) or more -

ST-S Straight Shank Shrink-Fit Holder

MANYO TOOLS

[Features]

· The grip strength is 3 times that of the collet chuck.

· Thin with little interference.

· A well balanced type. Ideal for high speed machining.

· Excellent runout accuracy 3D tips of 3 μm or less.

· Length can be adjusted freely.Standard Price: SGD 251.79- Days to Ship: 8 Day(s) or more -

MANYO TOOLS

[Features]

· A product lineup consisting of the ST20, T32, ST42, and ST50.8Standard Price: SGD 197.94- Days to Ship: 8 Day(s) or more -

MANYO TOOLS

[Features]

·Compatible with MTB morse taper holder B type.

·Compatible with a wide variety of cutters.

Please attach the drawing screw type morse taper cutting tool.

·Minimum order quantity: 1 pc.Standard Price: SGD 134.01- Days to Ship: 6 Day(s) or more -

Standard Price: SGD 187.04 Days to Ship: 6 Day(s) or more -

Standard Price: SGD 187.04 Days to Ship: 6 Day(s) or more -

Standard Price: SGD 198.57 Days to Ship: 6 Day(s) or more -

Standard Price: SGD 198.57 Days to Ship: 6 Day(s) or more -

Standard Price: SGD 210.09 Days to Ship: 6 Day(s) or more -

Standard Price: SGD 210.09 Days to Ship: 6 Day(s) or more -

Standard Price: SGD 134.01 Days to Ship: 6 Day(s) or more -

Standard Price: SGD 134.01 Days to Ship: 6 Day(s) or more -

Standard Price: SGD 145.54 Days to Ship: 6 Day(s) or more -

Standard Price: SGD 145.54 Days to Ship: 6 Day(s) or more -

Standard Price: SGD 173.21 Days to Ship: 6 Day(s) or more -

KATO MFG

[Features]

· Eliminates concerns about synchronization errors

· Thin pencil type

· Function is limited to tension (shallow screw set prevention)

· In combination with a TCA-S collet, it is the same length as a conventional SA-III type tapper, and so can be replaced without having to change the program.

· Tension prevents chipping, etc. even in difficult-to-machine materialsStandard Price: SGD 437.07- Days to Ship: 9 Day(s) or more -

KATO MFG

[Features]

·Wrench dedicated to RF type tapping tool.

·Minimum order quantity: 1 pc.

·Tapping tool used: RF306/RF414,RF414-OHCStandard Price: SGD 77.64- Days to Ship: 9 Day(s) or more -

SA Series HA-M-OHC Type Tapper

KATO MFG

[Features]

· HA-M type that supports center through coolant

· Characteristics and specifications conform to the HA-M type

· The flange through oil hole type (-OHF) is available upon order

· Unlike the spring collet, tap attachment and detachment can be performed in a single action

· Remeasurement of tool length after tap replacement is unnecessary

· The standard specification uses the TC-MO with feed pump pressures up to 2 MPa.

· Use the TC-MO-SB to handle feed pump pressures up to 5 MPa.

· Also Supports Mist SpecificationsStandard Price: SGD 596.33 Days to Ship: 7 Day(s) or more -

SA Series MT-SA-III Type Tapper (Morse Taper Shank)

KATO MFG

[Features]

· Best-selling "Kato Tapper"

· Sizing type screw depth built-in limiting device

· Tapper that works with all machinery, workpieces, and cutting conditions

· Ideal for machining valuable workpieces such as prototypes, single articles, molds, etc.

· The specifications, such as the strength of the spring and extension/contraction amount, can be changed to match the usage conditions.

· The expansion device absorbs feed errors to realize high thread accuracyStandard Price: SGD 545.75 Days to Ship: 9 Day(s) or more -

SA Series ST-SA-VI Type Tapper (Straight Shank for Milling Chuck)

KATO MFG

[Features]

· Short body type that can be used in various machines

· Expansion Device to Absorb Feed Errors

· Short Type Ideal for Narrow Work SpacesStandard Price: SGD 693.40 Days to Ship: 9 Day(s) or more -

SA Series MT-HA Type Tapper (Morse Taper Shank)

KATO MFG

[Features]

· Simple structure and easy operation

· For Tapping Drilling Machine

· For Standing or Radial Drilling Machines

· Ideal for work in tight spaces due to its slender and short bodyStandard Price: SGD 232.72- Days to Ship: 7 Day(s) or more -

KATO MFG

[Features]

· Drills and Taps for Standing and Radial Drilling Machines

· Quick Change set

· The drill and tap can be replaced in a single touch on the same coreStandard Price: SGD 2,611.85 Days to Ship: 9 Day(s) or more -

Special-Purpose Taper Collet for Drill Tappers

KATO MFG

KATO MFG., taper collet dedicated to drill tapping tool

[Features]

·GMC type

·Minimum order quantity: 1 pc.

·Compatible GM type: GM3 × 3/GM4 × 3/GM4 × 4/GM5 × 4Standard Price: SGD 211.91- Days to Ship: 9 Day(s) or more -

Special-Purpose Magic Chuck for Drill Tappers

KATO MFG

[Features]

An upright, radial ball-only drill / power strip quick-change set.

A GM-type magic chuck.

·Holder length: 84.5 mm / 90.5 mm / 97.5 mm

·Shank: MT3/MT4

·Supported MA type: 3MA412,3MA1022/4MA412,4MA1022,4MA2035Standard Price: SGD 571.79- Days to Ship: 9 Day(s) or more -

TAKURA KOGU

Shaft for ED Chuck

[Features]

· It has outstanding operability / grasping force / high precision. The drawbar method reduces core runout, and the accuracy is high (within 0.01)

· The collet taper part is long so the grip range remains rigid.

· Adjustment screws are attached to the bore and blades can be inserted and taken out easily and freelyStandard Price: SGD 582.50- Days to Ship: 6 Day(s) or more -

TAKURA KOGU

ED Chuck Collets

[Features]

· It has outstanding operability / grasping force / high precision. The drawbar method reduces core runout, and the accuracy is high (within 0.01)

· The collet taper part is long so the grip range remains rigid.

· Adjustment screws are attached to the bore and blades can be inserted and taken out easily and freelyStandard Price: SGD 71.76 Days to Ship: 6 Day(s) or more -

Slip hardened abrasive article

TAKURA KOGU

[Features]

· Used when aligning the dimensions of the Morse taper shank of a drill or the like to the spindle of a drilling machine, etc.Standard Price: SGD 50.55- Days to Ship: 4 Day(s) or more -

TAKURA KOGU

[Features]

・ Special shaft sleeve

·Minimum order quantity: 1 pc.

·Overall length (mm): 85/100/137/157Standard Price: SGD 113.64- Days to Ship: 9 Day(s) or more -

TAKURA KOGU

[Features]

・ Hardening and polishing product

· Long type

·Minimum order quantity: 1 pc.

·Capacity: 1 pc.Standard Price: SGD 158.35- Days to Ship: 4 Day(s) or more -

Turret Sleeve Hardened and Polished MT1

TAKURA KOGU

[Features]

· This is a quenched and polished product.

· Used when straight shafts are changed to Morse taper shafts in milling machines and machining centers.Standard Price: SGD 105.89- Days to Ship: 4 Day(s) or more -

TAKURA KOGU

[Features]

Hardening and ground S-axis chuck arbor.

Because it is hardening and ground product, it has excellent runout accuracy and taper contact, as well as excellent durability.Standard Price: SGD 66.79- Days to Ship: 4 Day(s) or more -

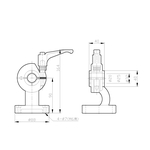

TAKURA KOGU

[Features]

· By simply mounting onto the tool holder of a lathe, drilling can be done with a powerful automatic feed

· Many Drill Types Instantly Exchangeable for Use

· As with drill sleeves in drill presses, if used once with a lathe it will be used again, leading to greater efficiency.

· Finally, adjust with shim boardsStandard Price: SGD 243.46 Days to Ship: 9 Day(s) or more -

TAKURA KOGU

[Features]

·Screw that converts the drawing threaded type of MT/BS into TANG type.

Minimum order quantity: 1 pc.Standard Price: SGD 16.53- Days to Ship: 6 Day(s) or more -

Standard Price: SGD 191.75- Days to Ship: 6 Day(s) or more -

TAKURA KOGU

[Features]

Arbor for attaching side milling cutter.

[Applications]

Ideal for cutting blocks, etc.Standard Price: SGD 1,125.63 Days to Ship: 6 Day(s) or more -

Side Cutter Arbor Component (Milling Collar)

TAKURA KOGU

[Features]

A milling collar for side milling cutter arbors.

·Overall length (D): 40,48,55 mmStandard Price: SGD 13.29- Days to Ship: 4 Day(s) or more -

Front Face Mill Cutter Arbor (S Shaft)

TAKURA KOGU

[Features]

Front milling machine cutter arbor for mounting an S-axis cutter.

Included bolt is hex socket head cap screw.

(Other than d = 40)Standard Price: SGD 200.91 Days to Ship: 6 Day(s) or more -

Front Face Mill Cutter Arbor (NT)

TAKURA KOGU

[Features]

・ Arbor for attaching NT axis cutter.

·Minimum order quantity: 1 pc.Standard Price: SGD 292.15 Days to Ship: 6 Day(s) or more -

Side Locking Holder (Direct Mounting Type)

TAKURA KOGU

[Features]

·Locking holder with drawing screw

·Minimum order quantity: 1 pc.

·Spindle/shank shape: NT (national taper)

·Spindle/shank type: MCA (NIKKEN)

·Spindle/shank number: 50Standard Price: SGD 452.73 Days to Ship: 9 Day(s) or more -

Center ring plug (direct attachment type)

TAKURA KOGU

TAKURA TOOLING SYSTEM. centering plug (Direct mounting type)

[Features]

・ Direct mount type

·Minimum order quantity: 1 pc.Standard Price: SGD 226.37- Days to Ship: 9 Day(s) or more -

Surface mounting drill for tap hole

TAKURA KOGU

[Features]

· Center drilling, hole tapping and chamfering can be done in a single step.

· As it is a side lock type, it produces very little center runout and is easy to install.Standard Price: SGD 75.44- Days to Ship: 4 Day(s) or more -

Standard Price: SGD 425.43- Days to Ship: 10 Day(s) -

BIG DAISHOWA SEIKI

[Features]

· Accommodates φ20, φ25, and φ32 straight shank diameters.

· Ideal for fixing straight shanks and tightening nuts.Standard Price: SGD 481.32 Days to Ship: 11 Day(s) -

BIG DAISHOWA SEIKI

[Features]

· The taper and flange face are cleaned simultaneously.Standard Price: SGD 59.09- Days to Ship: 11 Day(s)

| Brand |

|---|

| Product Series |

| Days to Ship |

| Spindle types |

| HSK type |

| Tool Type |

| Retainable blade diameter(mm) |

| Product Category |

| Applicable Manufacturing Machinery (main unit) |

| Chuck Type |

| Holder Length L(mm) |

| Maximum Allowable Rotational Speed(min-1) |

| Coolant System |

| Nozzle Type |

| Brand | MANYO TOOLS | MANYO TOOLS | MANYO TOOLS | MANYO TOOLS | MANYO TOOLS | MANYO TOOLS | MANYO TOOLS | MANYO TOOLS | MANYO TOOLS | MANYO TOOLS | MANYO TOOLS | MANYO TOOLS | MANYO TOOLS | MANYO TOOLS | MANYO TOOLS | MANYO TOOLS | KATO MFG | KATO MFG | KATO MFG | KATO MFG | KATO MFG | KATO MFG | KATO MFG | KATO MFG | KATO MFG | TAKURA KOGU | TAKURA KOGU | TAKURA KOGU | TAKURA KOGU | TAKURA KOGU | TAKURA KOGU | TAKURA KOGU | TAKURA KOGU | TAKURA KOGU | TAKURA KOGU | TAKURA KOGU | TAKURA KOGU | TAKURA KOGU | TAKURA KOGU | TAKURA KOGU | TAKURA KOGU | TAKURA KOGU | NT TOOL | BIG DAISHOWA SEIKI | BIG DAISHOWA SEIKI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Product Series | SA Series ST-SA-VI Type Tapper (Straight Shank for Milling Chuck) | ||||||||||||||||||||||||||||||||||||||||||||

| Days to Ship | 18 Day(s) or more | 18 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 9 Day(s) or more | 9 Day(s) or more | 7 Day(s) or more | 9 Day(s) or more | 9 Day(s) or more | 7 Day(s) or more | 9 Day(s) or more | 9 Day(s) or more | 9 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 4 Day(s) or more | 9 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 9 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 4 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 9 Day(s) or more | 9 Day(s) or more | 4 Day(s) or more | 10 Day(s) | 11 Day(s) | 11 Day(s) |

| Spindle types | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | BT40 | - | BT50 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | BT30 | - | BT30 / BT40 |

| HSK type | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Tool Type | - | end mill | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | Reamer | end mill | end mill | - | - | - | - | - | end mill / drill / Reamer | - | - |

| Retainable blade diameter(mm) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 0.5~7 ~ 2.5~9 | - | - |

| Product Category | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Main Body | Attachments/Accessories | Main Body | Attachments/Accessories | Main Body | Attachments/Accessories | Main Body | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Attachments/Accessories | Main Body | Attachments/Accessories | Main Body | Main Body | Main Body | Main Body | Attachments/Accessories | Main Body | Attachments/Accessories | Attachments/Accessories |

| Applicable Manufacturing Machinery (main unit) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | Machining Centers | - | Machining Centers | - | Generic Machine | - | Generic Machine | - | - | - | - | - | - | - | - | - | - | - | - | Generic Machine | - | Generic Machine | Generic Machine | Machining Centers | Generic Machine | - | Machining Centers | - | - |

| Chuck Type | - | - | Shrink fit | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Holder Length L(mm) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 150 ~ 195 | - | 165 | 132 | 93 | 93 ~ 176.5 | - | - | 84.5 ~ 97.5 | 75 ~ 160 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 75 ~ 90 | - | - |

| Maximum Allowable Rotational Speed(min-1) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Coolant System | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Nozzle Type | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

Loading...

Configure

Specification/Dimensions

-

Spindle types

-

HSK type

-

Tool Type

-

Retainable blade diameter(mm)

- 0.25~0.50

- 0.25~ 6

- 0.3~3

- 0.4–0.5

- 0.45 ~0.55

- 0.45~3.25

- 0.45~4.05

- 0.45~6.05

- 0.5 to 0.75

- 0.50 to 0.75

- 0.5~5.0

- 0.5~ 6

- 0.5~6.5

- 0.5~7

- 0.5~7.0

- 0.5 ~ 8

- 0.5~8

- 0.5~ 8

- 0.5–10

- 0.5~10.0

- 0.5~13

- 0.5~13.0

- 0.5~16.0

- 0.55 ~0.65

- 0.6~0.7

- 0.65 ~0.75

- 0.7~0.8

- 0.75 ~0.85

- 0.75~1.0

- 0.75~1.00

- 0.8~0.9

- 0.8~6.5

- 0.85 ~0.95

- 0.9 to 1.0

- 0.95 ~1.05

- 1

- 1.0~0.5

- 1.0~1.1

- 1.0~1.25

- 1.00~1.25

- 1.0~6.0

- 1.0~8.0

- 1.0~10

- 1 to 13

- 1.05 ~1.15

- 1.15 ~1.25

- 1.2~1.3

- 1.25 ~1.35

- 1.25~1.5

- 1.25~1.50

- 1.35 ~1.45

- 1.4 to 1.5

- 1.45 ~1.55

- 1.5

- 1.5-13

- 1.5~1.0

- 1.5–1.6

- 1.50~1.75

- 1.5~1.75

- 1.5 to 10

- 1.5 ~10

- 1.5~13

- 1.5~20.0

- 1.55 ~1.65

- 1.6 to 1.7

- 1.65 ~1.75

- 1.7 to 1.8

- 1.75 ~1.85

- 1.75~2.0

- 1.75~2.00

- 1.8~1.9

- 1.85 ~1.95

- 1.9~2.0

- 1.95 ~2.05

- 2

- 2.0~1.5

- 2.0~2.1

- 2.0~2.25

- 2.00~2.25

- 2.0~10.0

- 2.05 ~2.15

- 2.1~2.2

- 2.15 ~2.25

- 2.2~2.3

- 2.25 ~2.35

- 2.25~2.5

- 2.25~2.50

- 2.3~2.4

- 2.35 ~2.45

- 2.4~2.5

- 2.45 ~2.55

- 2.5

- 2.5 to 2.0

- 2.5~2.6

- 2.5~2.75

- 2.50~2.75

- 2.5–3.0

- 2.5~9

- 2.5~12

- 2.5 to 13

- 2.5 ~13

- 2.5~13

- 2.5 to 16

- 2.5 ~16

- 2.5~16.0

- 2.5 to 20

- 2.5 ~20

- 2.5~20.0

- 2.5~20

- 2.55 ~2.65

- 2.6~2.7

- 2.65 ~2.75

- 2.675~3.175

- 2.7~2.8

- 2.75 ~2.85

- 2.75~3.0

- 2.75~3.00

- 2.75~3.25

- 2.8~2.9

- 2.85 ~2.95

- 2.9~3.0

- 2.925~3.175

- 2.95 ~3.05

- 2.95~3.05

- 2.95 to 8.05

- 2.95~8.05

- 3

- 3.0~2.5

- 3.0~3.1

- 3.00~3.25

- 3~3.5

- 3.0–3.5

- 3–4

- 3–6

- 3~ 6

- 3~ 8

- 3–10

- 3 to 12

- 3.0~12.5

- 3 to 16

- 3.0~16.0

- M3 to M16

- 3.0~20.0

- 3.05 ~3.15

- 3.05~3.15

- 3.1~3.2

- 3.125~3.225

- 3.15 ~3.25

- 3.15~3.25

- 3.175

- 3.2~3.3

- 3.2~3.4

- 3.25 ~3.35

- 3.25~3.35

- 3.25~3.50

- 3.25~3.75

- 3.3–3.4

- 3.35 ~3.45

- 3.35~3.45

- 3.4~3.5

- 3.40~3.50

- 3.4~3.6

- 3.45 ~3.55

- 3.45~3.55

- 3.5~3.0

- 3.5~3.6

- 3.50~3.75

- 3.5~4.0

- 3.5~16

- 3.5~20.0

- 3.5~22

- 3.55 ~3.65

- 3.55~3.65

- 3.6~3.8

- 3.65 ~3.75

- 3.65~3.75

- 3.7~3.8

- 3.75 ~3.85

- 3.75~3.85

- 3.75~4.00

- 3.75~4.25

- 3.75~ 4.25

- 3.8~3.9

- 3.85 ~3.95

- 3.85~3.95

- 3.9~4.0

- 3.90~4.00

- 3.95 ~4.05

- 3.95~4.05

- 4

- 4.0~3.5

- 4.0~4.1

- 4.0 to 4.2

- 4.00~4.25

- 4~4.5

- 4.0–4.5

- 4–5

- 4.05 ~4.15

- 4.05~4.15

- 4.1~4.2

- 4.15 ~4.25

- 4.15~4.25

- 4.2~4.3

- 4.2~4.4

- 4.25 ~4.35

- 4.25~4.35

- 4.25~4.50

- 4.25~4.75

- 4.25~ 4.75

- 4.3~4.4

- 4.35 ~4.45

- 4.35~4.45

- 4.4~4.5

- 4.40~4.50

- 4.4~4.6

- 4.45 ~4.55

- 4.45~4.55

- 4.5~4.0

- 4.5~4.6

- 4.50~4.75

- 4.5–5.0

- 4.55 ~4.65

- 4.55~4.65

- 4.6~4.7

- 4.6~4.8

- 4.65 ~4.75

- 4.65~4.75

- 4.7~4.8

- 4.7125~4.8125

- 4.75 ~4.85

- 4.75~4.85

- 4.75~5.00

- 4.75 to 5.25

- 4.8~4.9

- 4.85 ~4.95

- 4.85~4.95

- 4.9~5.0

- 4.90~5.00

- 4.95 ~5.05

- 4.95~5.05

- 5

- 5.0~4.0

- 5.0~4.5

- 5.00~5.25

- 5.0~5.5

- 5~5.5

- 5–6

- 5.0~25.0

- 5.0~32.0

- 5.05 ~5.15

- 5.05~5.15

- 5.1~5.2

- 5.15 ~5.25

- 5.15~5.25

- 5.2~5.3

- 5.25 ~5.35

- 5.25~5.35

- 5.25~5.50

- 5.25~5.75

- 5.3~5.4

- 5.35 ~5.45

- 5.35~5.45

- 5.4~5.5

- 5.40~5.50

- 5.45 ~5.55

- 5.45~5.55

- 5.5

- 5.5~5.0

- 5.5~5.6

- 5.50~5.75

- 5.5 to 6.0

- 5.5–6.0

- 5.55 ~5.65

- 5.55~5.65

- 5.6~5.7

- 5.65 ~5.75

- 5.65~5.75

- 5.7~5.8

- 5.75 ~5.85

- 5.75~5.85

- 5.75~6.00

- 5.8~5.9

- 5.85 ~5.95

- 5.85~5.95

- 5.9~6.0

- 5.90~6.00

- 5.95 ~6.05

- 5.95~6.05

- 6

- 6.0~5.0

- 6.0~5.5

- 6 to 6.5

- 6.0–6.5

- 6–7

- 6.0~25.0

- 6.05~6.15

- 6.15~6.25

- 6.2

- 6.25~6.35

- 6.35~6.45

- 6.4~6.5

- 6.45~6.55

- 6.5~6.0

- 6.5 to 7.0

- 6.55~6.65

- 6.65~6.75

- 6.75~6.85

- 6.85~6.95

- 6.9~7.0

- 6.95~7.05

- 7

- 7.0~6.0

- 7.0~6.5

- 7.0~7.5

- 7~7.5

- 7–8

- 7.05~7.15

- 7.15~7.25

- 7.25~7.35

- 7.35~7.45

- 7.4~7.5

- 7.45~7.55

- 7.5~8.0

- 7.55~7.65

- 7.65~7.75

- 7.75~7.85

- 7.85~7.95

- 7.9~8.0

- 7.95~8.05

- 8

- 8.0~7.0

- 8~8.5

- 8.0~8.5

- 8–9

- 8.4~8.5

- 8.5

- 8.5~9.0

- 8.9~9.0

- 9

- 9.0~8.0

- 9.0~9.5

- 9~9.5

- 9–10

- 9.4~9.5

- 9.5 to 10.0

- 9.9~10.0

- 10

- 10.0~9.0

- 10.0 ~10.5

- 10.0~10.5

- 10~10.5

- 10~11

- 10.4~10.5

- 10.5

- 10.5~11.0

- 10.9~11.0

- 11

- 11.0~10.0

- 11.0~11.5

- 11~11.5

- 11~12

- 11.4~11.5

- 11.5~12.0

- 11.9~12.0

- 12

- 12.0~11.0

- 12.0~12.5

- 12~12.5

- 12~13

- 12.4~12.5

- 12.5

- 12.5~13.0

- 12.9~13.0

- 13

- 13.0~12.0

- 13.0~13.5

- 13~14

- 13.4~13.5

- 13.5~14.0

- 13.9~14.0

- 14

- 14.0~13.0

- 14.0~14.5

- 14~15

- 14.4~14.5

- 14.5~15.0

- 14.9~15.0

- 15

- 15.0~14.0

- 15.0~15.5

- 15~16

- 15.4~15.5

- 15.5~16.0

- 15.9~16.0

- 16

- 16.0~15.0

- 16.0~16.5

- 16~17

- 16.0~32.0

- 16.4~16.5

- 16.5

- 16.5~17.0

- 16.9~17.0

- 17.0~16.0

- 17.0~17.5

- 17~18

- 17.4~17.5

- 17.5~18.0

- 17.9~18.0

- 18

- 18.0~17.0

- 18.0~18.5

- 18~19

- 18.4~18.5

- 18.5~19.0

- 18.9~19.0

- 19

- 19.0~18.0

- 19.0~19.5

- 19~20

- 19.4~19.5

- 19.5~20.0

- 19.9~20.0

- 20

- 20.0~19.0

- 21

- 21.0~20.0

- 22

- 22.0~21.0

- 23

- 23.0~22.0

- 24

- 24.0~23.0

- 25

- 25.0~24.0

- 28.0~27.0

- 30.0~29.0

- 32

- 32.0~31.0

- M36

- 38

- 39

- 40

- 42

- 50

- 50.8

-

Product Category

-

Applicable Manufacturing Machinery (main unit)

-

Chuck Type

-

Holder Length L(mm)

- 10.5

- 15.5

- 16

- 16.5

- 19.5

- 20

- 24.5

- 25

- 26.5

- 29

- 30

- 33

- 34

- 35

- 35.5

- 37

- 38.3

- 39

- 40

- 43

- 44

- 44.1

- 45

- 47

- 48

- 50

- 52

- 53

- 54

- 54.4

- 54.6

- 55

- 55.5

- 60

- 62

- 62.5

- 65

- 67.5

- 68.5

- 70

- 73

- 74

- 75

- 76.7

- 77

- 80

- 81

- 84.5

- 85

- 90

- 90.5

- 91

- 92

- 93

- 94.5

- 95

- 95/135/165

- 96

- 97.5

- 100

- 100/140/170

- 105

- 105/145/175

- 107

- 107.5

- 109.5

- 110

- 115

- 120

- 120/160/190

- 121

- 122

- 125

- 125/175/205

- 130

- 130/180/210

- 131.5

- 132

- 135

- 137

- 137.5

- 140

- 140/190/220

- 145/195/225

- 150

- 155

- 160

- 162.5

- 164.5

- 165

- 167

- 167.5

- 169

- 176.5

- 180

- 180.5

- 182.5

- 185

- 186.5

- 190

- 193.5

- 195

- 200

- 202.5

- 210

- 220

- 225

- 240

- 250

- 255

- 300

- 350

-

Maximum Allowable Rotational Speed(min-1)

-

Coolant System

-

Nozzle Type

Narrow search by specifying Manufacturer

-

- BIG DAISHOWA SEIKI (130)

- YUKIWA SEIKO (89)

- TRUSCO NAKAYAMA (62)

- MANYO TOOLS (47)

- ESCO (40)

- TAKURA KOGU (22)

- KATO MFG (14)

- SHOWA TOOL (12)

- NOGA JAPAN (11)

- SUMITOMO ELECTRIC HARDMETAL (10)

- NT TOOL (7)

- SANDVIK (6)

- FUSOSEIKI (5)

- THE CUT (5)

- VESSEL (5)

- NIIGATA SEIKI (SK) (4)

- NIKKI TRADING (4)

- KASAHARA (3)

- MITSUTOMO (3)

- OSG (3)

- TSCHORN (3)

- VERTEX (3)

- DREMEL (2)

- FUJI TOOL (2)

- NEW STRONG (2)

- ALBRECHT (1)

- GIGA SELECTION (1)

- KOBAYASHI IRON WORKS (1)

- KYORITSU SEIKI (1)

- MINITOR (1)

- MARVEL (1)

- NABEYA (1)

- NIKKENKOSAKU (1)

- NAKANISHI (1)

- SUGINO MACHINE (1)

- SHINWASOKUTEI (1)

- TOHIN SHOJI (1)

CAD

-

- 2D

- 3D

How can we improve?

How can we improve?