(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla Firefox.

50,000 Stock items for Same Day Ship Out.

All Categories

Categories

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Application

Brands

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 9:00 9/2/2025 to 7:00 (SGT) 10/2/2025. We apologize for the inconvenience.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Solenoid Valves(Number of Solenoids:Double Page4)

| Days to Ship |

|

|---|

-

3-Port 3-Position Valve VEX3 Series (Air Operated / Pilot Solenoid)

SMC

An SMC 3-position valve with 3 manual operating methods added.

[Features]

· Intermediate stopping of cylinders with a maximum ø125 (diameter 125 mm) is possible.

· Power consumption: 1 W.

· Body ported type.

· Body type: Air-operated type S / pilot solenoid type.

· Thread type: Rc, G, NPT.

· Operating method: External pilot solenoid type / Internal pilot solenoid type.Days to Ship: 32 Day(s) or more -

5-Port Solenoid Valve, Base Mounted, Single Unit SX3000/5000/7000 Series

SMC

SMC Solenoid Valve.

[Features]

· The pilot valve is concentrated on one side with its wiring gathered as one, giving it a neat and tidy appearance

· Low power consumption at just 0.6 W

· High reliability and long service life of 50 million cycles or more

· Compact and with a large flow capacity

· High speed response of 10 ms

· Improved drain resistance adaptability

· Suitable for use in copper and fluorine-free applications

· Attractive design with bright color tones

· Consolidation of indicator lights and manual

· Removal of pilot valve exhaust mist and sound

· Uses a common base with the SY Series

· The cylinder port size can be changedDays to Ship: Quote -

5-Port Solenoid Valve, Pilot Operated, VZS3000

SMC

SMC Solenoid Valve.

[Features]

· One-touch connection D-sub connector (MIL standard-compliant) for reduced wiring cost

· Excellent flow rate characteristics in a compact size (width: 18 mm)

· Easy to increase and decrease the number of manifold stations

· High operational frequency and a long product life (30,000,000 cycles or more), oil-free and can be used for dry-air operations

· Multiple wiring variations

· Low power consumption at just 1.8 W DC and supports serial transmission systemsDays to Ship: 32 Day(s) or more -

5 Port Solenoid Valve, Plug-in Unit Clean Series 10-SQ1000 Series

SMC

[10-Series Clean Series]

・ This product can be used in a clean environment.

・ Prevents dust generation in the cleanroom.Days to Ship: Quote -

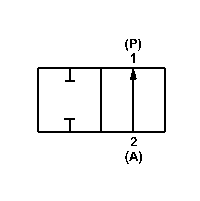

Vacuum Release Valve With Throttle Valve SJ3A6 Series

SMC

[Features]

・ 2 built-in spool valves.

· Control vacuum suction/release with one valve.

・ 10 mm width. (Same size as SJ3000 series)

・ With a throttle valve that can adjust the flow rate of break air.

・ Built-in replaceable filters on both vacuum side and break side.

・ It can be mixed with 4 port solenoid valve SJ2000/3000. (Made-to-order)Days to Ship: 32 Day(s) or more -

5 Port Solenoid Valve, Plug-in Type S0700 Series

SMC

[Features]

・ A wide variety of centralized wiring methods.

・ Slim compact manifold.

Installation space reduced by 45%.

Height reduced by 20 mm.

Comparison of split type manifolds.

・ 4-position dual 3-port valve.

・ Manifold model: SS0751, SS0750。Days to Ship: Quote -

5-Port Solenoid Valve, Low Wattage Specification VF1000/3000 Series

SMC

[Features]

・ Built-in full-wave rectifier (For AC)

· The pilot valve features a built-in strainer

・ Manifold model: VV5F1, VV5F3, VV5F5

・ Low wattage specificationsDays to Ship: 32 Day(s) or more -

3-Port Solenoid Valve VV100 Series

SMC

A valve for a highly integrated unit manifold with 2 direct-acting 3-port valves mounted in 1 station.

[Please click here for the catalog]

P. 1897 Plug-in

P. 1905 Dedicated for Non Plug-in Individual WiringDays to Ship: 32 Day(s) or more -

SMC

[Rechargeable battery compatible series]

Copper (Cu) and zinc (Zn) materials are not used in the rechargeable battery manufacturing process to reduce product defects.

Some aluminum alloys and die-cast aluminum materials contain small amounts of copper (Cu) and zinc (Zn) as additive elements.

Electrolytic nickel plating and zinc plating with copper base are not used. (Electroless nickel plating is used.)

It uses low dew point compatible grease, -70°C compatible, improved performance in low dew point environment.Days to Ship: 32 Day(s) or more -

5-Port Solenoid Valve, Starter Unit, Base Mounted, Rechargeable Battery Compatible, 25A-VQ4000

SMC

[Rechargeable battery compatible series]

Copper (Cu) and zinc (Zn) materials are not used in the rechargeable battery manufacturing process to reduce product defects.

Some aluminum alloys and die-cast aluminum materials contain small amounts of copper (Cu) and zinc (Zn) as additive elements.

Electrolytic nickel plating and zinc plating with copper base are not used. (Electroless nickel plating is used.)

It uses low dew point compatible grease, -70°C compatible, improved performance in low dew point environment.Days to Ship: Quote -

5-Port Solenoid Valve, Plug-in Type, Compatible With Rechargeable Batteries 25A-SQ2000 Series

SMC

[Rechargeable battery compatible series]

Copper (Cu) and zinc (Zn) materials are not used to reduce product defects in the rechargeable battery manufacturing process.

Some aluminum alloys and die-cast aluminum materials contain small amounts of copper (Cu) and zinc (Zn) as additive elements.

Electrolytic nickel plating with copper base and zinc plating are not used. (Electroless nickel plating is used. )

It uses low dew point compatible grease, -70°C compatible, improved performance in low dew point environment.Days to Ship: Quote -

5-Port Solenoid Valve, Plug Lead Type, Compatible With Rechargeable Batteries 25A-SQ2000 Series

SMC

[Rechargeable battery compatible series]

Copper (Cu) and zinc (Zn) materials are not used to reduce product defects in the rechargeable battery manufacturing process.

Some aluminum alloys and die-cast aluminum materials contain small amounts of copper (Cu) and zinc (Zn) as additive elements.

Electrolytic nickel plating with copper base and zinc plating are not used. (Electroless nickel plating is used. )

It uses low dew point compatible grease, -70°C compatible, improved performance in low dew point environment.Days to Ship: Quote -

5-Port Solenoid Valve, Body Ported, Plug Lead Unit, Rechargeable Battery Compatible, 25A-VQZ1000

SMC

[Rechargeable battery compatible series]

Copper (Cu) and zinc (Zn) materials are not used to reduce product defects in the rechargeable battery manufacturing process.

Some aluminum alloys and die-cast aluminum materials contain small amounts of copper (Cu) and zinc (Zn) as additive elements.

Electrolytic nickel plating with copper base and zinc plating are not used. (Electroless nickel plating is used. )

It uses low dew point compatible grease, -70°C compatible, improved performance in low dew point environment.Days to Ship: Quote -

4 / 5 Port Solenoid Valve, Elastic Seal, Clean Series 10-SYJ3000 Series

SMC

[10-Series, Clean Series]

・ Suitable for clean environment

· It prevents dust generation in the cleanroomDays to Ship: 32 Day(s) or more -

5-Port Solenoid Valve, Elastic Seal, Clean Series 10-SYJ5000 Series

SMC

[10-Series, Clean Series]

・ Suitable for clean environment

· It prevents dust generation in the cleanroomDays to Ship: 32 Day(s) or more -

5 Port Solenoid Valve, Elastic Seal, Clean Series 10-SYJ7000 Series

SMC

[10-Series, Clean Series]

・ Suitable for clean environment

· It prevents dust generation in the cleanroomDays to Ship: 32 Day(s) or more -

3-Port 3-Position Valve, Base Piping Type VEX3 Series

SMC

[Features]

・ Intermediate stop of cylinder with maximum ø125 is possible

・ Power consumption: 1 W

・ 4 manual operation methods

Non-lock push type

Locking type, screwdriver operated

Push-turn locking slotted type

Push-turn locking (manual-operation type)Days to Ship: 32 Day(s) or more -

5-Port Solenoid Valve, Clean Series 10-SV1000/2000/3000/4000 Series

SMC

[10-Series, Clean Series]

・ Suitable for clean environment

· It prevents dust generation in the cleanroom

[Please click here for the catalog]

P.184 EX500 Distributed serial wiring support

P.265 Single unit / sub plate type [IP67 compliant]Days to Ship: 32 Day(s) or more -

SMC

Can only be used in Japan as an intrinsically safe explosion-proof structure certified product

・ Exia II BT4 (TIIS certified product)

This product has been certified as an intrinsically safe explosion-proof system that combines an electromagnet for solenoid valves and a safety cage in the explosion-proof structure electromechanical equipment type certification of the Industrial Safety Technology Association of Japan (TIIS).

* Due to the system display and the selection of the attached barrier, the B (Zener type) barrier has been discontinued (December, 2017). Select A (Zener type) or F (Insulated type).Days to Ship: Quote -

CSA Standard Compliant, 5-Port Solenoid Valve, Pilot Operated, Metal Seal, VFS2000

SMC

CSA standard compliant, 5-port solenoid valve pilot type metal seal non-plug-in type.

Days to Ship: 32 Day(s) or more -

CSA Standard Compliant, 5-Port Solenoid Valve, Pilot Operated, Metal Seal, VFS3000

SMC

CSA standard compliant, 5-port solenoid valve pilot type metal seal non-plug-in type.

Days to Ship: 32 Day(s) or more -

CSA Standard Compliant, 5-Port Solenoid Valve, Pilot Operated, Metal Seal, VFS4000

SMC

CSA standard compliant, 5-port solenoid valve pilot type metal seal non-plug-in type.

Days to Ship: 32 Day(s) or more -

CSA Standard Compliant, 5-Port Solenoid Valve, Pilot Operated, Metal Seal, VFS5000

SMC

CSA standard compliant, 5-port solenoid valve pilot type metal seal non-plug-in type.

Days to Ship: 32 Day(s) or more -

CSA Standard Compliant 5-Port Solenoid Valve, Pilot Operated, Elastic Material Seal, VFR2000

SMC

CSA standard compliant, 5-port solenoid valve pilot type elastic seal non-plug-in type.

Days to Ship: Quote -

CSA Standard Compliant, 5-Port Solenoid Valve, Pilot Operated, Elastic Seal, VFR3000

SMC

CSA standard compliant, 5-port solenoid valve pilot type elastic seal non-plug-in type.

Days to Ship: 32 Day(s) or more -

CSA Standard Compliant, 5-Port Solenoid Valve, Pilot Operated, Elastic Seal, VFR4000

SMC

CSA standard compliant, 5-port solenoid valve pilot type elastic seal non-plug-in type.

Days to Ship: 32 Day(s) or more -

ATEX Directive 5-Port Solenoid Valve, 56-VQC1000 Series, ATEX Category 3

SMC

[What is ATEX Directive?]

Since July 1, 2003, it has been mandatory within the EU to comply with the ATEX Directive for equipment used in potentially explosive atmospheres.

■CE mark and ATEX

The ATEX Directive is now part of the CE mark, which incorporates the traditional European explosion-proof standard.

■Purpose of ATEX Directive

The main purposes of ATEX are:

・ Prevention of electrostatic charge

・ Ignition prevention of sparks caused by friction, impact, and abrasion

・ Ignition prevention due to temperature rise due to the same as above

・ The responsibility lies with the manufacturer

・ Certification by zone/category

■Zone/Category

In ATEX, the objects to be applied are classified into categories for each dangerous place (zone).

・ Zone 0: Category 1

Possibility of explosive atmosphere (Zone): Continuous or long time > 1,000 hours/year

・ Zone 1: Category 2

Possibility of explosive atmosphere (Zone): occasionally 10 to 1,000 hours/year

・ Zone 2: Category 3

Possibility of explosive atmosphere (Zone): Less likely, short time < 10 hours/yearDays to Ship: Quote -

ATEX Directive 5-Port Solenoid Valve, 56-VQC2000 Series, ATEX Category 3

SMC

[What is ATEX Directive?]

Since July 1, 2003, it has been mandatory within the EU to comply with the ATEX Directive for equipment used in potentially explosive atmospheres.

■CE mark and ATEX

The ATEX Directive is now part of the CE mark, which incorporates the traditional European explosion-proof standard.

■Purpose of ATEX Directive

The main purposes of ATEX are:

・ Prevention of electrostatic charge

・ Ignition prevention of sparks caused by friction, impact, and abrasion

・ Ignition prevention due to temperature rise due to the same as above

・ The responsibility lies with the manufacturer

・ Certification by zone/category

■Zone/Category

In ATEX, the objects to be applied are classified into categories for each dangerous place (zone).

・ Zone 0: Category 1

Possibility of explosive atmosphere (Zone): Continuous or long time > 1,000 hours/year

・ Zone 1: Category 2

Possibility of explosive atmosphere (Zone): occasionally 10 to 1,000 hours/year

・ Zone 2: Category 3

Possibility of explosive atmosphere (Zone): Less likely, short time < 10 hours/yearDays to Ship: 32 Day(s) or more -

ATEX Directive 5-Port Solenoid Valve, 56-VQC4000 Series, ATEX Category 3

SMC

[What is ATEX Directive?]

Since July 1, 2003, it has been mandatory within the EU to comply with the ATEX Directive for equipment used in potentially explosive atmospheres.

■CE mark and ATEX

The ATEX Directive is now part of the CE mark, which incorporates the traditional European explosion-proof standard.

■Purpose of ATEX Directive

The main purposes of ATEX are:

・ Prevention of electrostatic charge

・ Ignition prevention of sparks caused by friction, impact, and abrasion

・ Ignition prevention due to temperature rise due to the same as above

・ The responsibility lies with the manufacturer

・ Certification by zone/category

■Zone/Category

In ATEX, the objects to be applied are classified into categories for each dangerous place (zone).

・ Zone 0: Category 1

Possibility of explosive atmosphere (Zone): Continuous or long time > 1,000 hours/year

・ Zone 1: Category 2

Possibility of explosive atmosphere (Zone): occasionally 10 to 1,000 hours/year

・ Zone 2: Category 3

Possibility of explosive atmosphere (Zone): Less likely, short time < 10 hours/yearDays to Ship: Quote -

5-Port Solenoid Valve, Base Mounted Type, Clean, 10-S0700

SMC

[10-Series, Clean Series]

Suitable for clean environment

Prevents dust generation in the cleanroomDays to Ship: Quote -

5-Port Solenoid Valve, Base Mounted, Clean, 10-VQ1000

SMC

[10-Series, Clean Series]

Suitable for clean environment

Prevents dust generation in the cleanroomDays to Ship: Quote -

5-Port Solenoid Valve, Base Mounted, Clean, 10-VQ2000

SMC

[10-Series, Clean Series]

Suitable for clean environment

Prevents dust generation in the cleanroomDays to Ship: Quote -

5-Port Solenoid Valve, Plug-in Type, Clean Series, 10-SZ3000 Series

SMC

[10-Series, Clean Series]

Suitable for clean environment

Prevents dust generation in the cleanroomDays to Ship: Quote -

5-Port Solenoid Valve Non-Plug-in Type Clean Series 10-SZ3000 Series

SMC

[10-Series, Clean Series]

Suitable for clean environment

Prevents dust generation in the cleanroomDays to Ship: Quote -

Guide integrated cylinder with valve Valve for MVGQ series (For ø12 to ø20)

SMC

Guide integrated cylinder with valve MVGQ series, valve for ø12 to ø20.

Days to Ship: Quote -

UL Standard Compliant Product, 5-Port Solenoid Valve, Plug-in Unit, Base Mounted, VQ1000 Series

SMC

UL standard compliant, 5-port solenoid valve, plug-in unit, base mounted.

Days to Ship: Quote -

UL Standard Compliant Product, 5-Port Solenoid Valve, Plug-in Unit, Base Mounted, VQ2000 Series

SMC

UL standard compliant, 5-port solenoid valve, plug-in unit, base mounted.

Days to Ship: Quote

| Brand |

|---|

| Product Series |

| CAD |

| Days to Ship |

| Number of Ports |

| Application |

| Switching Type |

| Voltage |

| Number of Solenoids |

| Mounting Orientation |

| Pipe Port Type |

| Specifications |

| Status at Power Off |

| Plumbing Thread Nominal |

| Plumbing |

| Applicable Cylinder Dia.(Ø) |

| Type |

| Driving Type |

| Connecting Tube Diameter |

| Pressure Rating(MPa) |

| Seal Type |

| CV Value |

| Pilot Air Supply |

| Brand | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC | SMC |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Product Series | 3-Port 3-Position Valve VEX3 Series (Air Operated / Pilot Solenoid) | 5-Port Solenoid Valve, Base Mounted, Single Unit SX3000/5000/7000 Series | 5 Port Solenoid Valve, Plug-in Unit Clean Series 10-SQ1000 Series | 5-Port Solenoid Valve, Low Wattage Specification VF1000/3000 Series | 5-Port Solenoid Valve, Starter Unit, Base Mounted, Rechargeable Battery Compatible, 25A-VQ4000 | 5-Port Solenoid Valve, Plug-in Type, Compatible With Rechargeable Batteries 25A-SQ2000 Series | 5-Port Solenoid Valve, Plug Lead Type, Compatible With Rechargeable Batteries 25A-SQ2000 Series | 5-Port Solenoid Valve, Body Ported, Plug Lead Unit, Rechargeable Battery Compatible, 25A-VQZ1000 | 4 / 5 Port Solenoid Valve, Elastic Seal, Clean Series 10-SYJ3000 Series | 5-Port Solenoid Valve, Elastic Seal, Clean Series 10-SYJ5000 Series | 5 Port Solenoid Valve, Elastic Seal, Clean Series 10-SYJ7000 Series | 5-Port Solenoid Valve, Clean Series 10-SV1000/2000/3000/4000 Series | CSA Standard Compliant, 5-Port Solenoid Valve, Pilot Operated, Metal Seal, VFS2000 | CSA Standard Compliant, 5-Port Solenoid Valve, Pilot Operated, Metal Seal, VFS3000 | CSA Standard Compliant, 5-Port Solenoid Valve, Pilot Operated, Metal Seal, VFS4000 | CSA Standard Compliant, 5-Port Solenoid Valve, Pilot Operated, Metal Seal, VFS5000 | CSA Standard Compliant 5-Port Solenoid Valve, Pilot Operated, Elastic Material Seal, VFR2000 | CSA Standard Compliant, 5-Port Solenoid Valve, Pilot Operated, Elastic Seal, VFR3000 | CSA Standard Compliant, 5-Port Solenoid Valve, Pilot Operated, Elastic Seal, VFR4000 | ATEX Directive 5-Port Solenoid Valve, 56-VQC1000 Series, ATEX Category 3 | ATEX Directive 5-Port Solenoid Valve, 56-VQC2000 Series, ATEX Category 3 | ATEX Directive 5-Port Solenoid Valve, 56-VQC4000 Series, ATEX Category 3 | 5-Port Solenoid Valve, Plug-in Type, Clean Series, 10-SZ3000 Series | 5-Port Solenoid Valve Non-Plug-in Type Clean Series 10-SZ3000 Series | Guide integrated cylinder with valve Valve for MVGQ series (For ø12 to ø20) | UL Standard Compliant Product, 5-Port Solenoid Valve, Plug-in Unit, Base Mounted, VQ1000 Series | UL Standard Compliant Product, 5-Port Solenoid Valve, Plug-in Unit, Base Mounted, VQ2000 Series | ||||||||||

| CAD |

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||||||

| Days to Ship | 32 Day(s) or more | Quote | 32 Day(s) or more | Quote | 32 Day(s) or more | Quote | 32 Day(s) or more | 32 Day(s) or more | 32 Day(s) or more | Quote | Quote | Quote | Quote | 32 Day(s) or more | 32 Day(s) or more | 32 Day(s) or more | 32 Day(s) or more | 32 Day(s) or more | Quote | 32 Day(s) or more | 32 Day(s) or more | 32 Day(s) or more | 32 Day(s) or more | Quote | 32 Day(s) or more | 32 Day(s) or more | Quote | 32 Day(s) or more | Quote | Quote | Quote | Quote | Quote | Quote | Quote | Quote | Quote |

| Number of Ports | 3-Port Valve | 5-Port Valve | 5-Port Valve | 5-Port Valve | 3-Port Valve | 5-Port Valve | 5-Port Valve | 3-Port Valve | 5-Port Valve | 5-Port Valve | 5-Port Valve | 5-Port Valve | 5-Port Valve | 4-Port Valve / 5-Port Valve | 5-Port Valve | 5-Port Valve | 3-Port Valve | 5-Port Valve | 5-Port Valve | 5-Port Valve | 5-Port Valve | 5-Port Valve | 5-Port Valve | 5-Port Valve | 5-Port Valve | 5-Port Valve | 5-Port Valve | 5-Port Valve | 5-Port Valve | 5-Port Valve | 5-Port Valve | 5-Port Valve | 5-Port Valve | 5-Port Valve | 4-Port Valve | 5-Port Valve | 5-Port Valve |

| Application | Single Use | Unit for Manifold Mounting | Single Use / Unit for Manifold Mounting | Unit for Manifold Mounting | Unit for Manifold Mounting | Manifolds / Unit for Manifold Mounting | Single Use / Unit for Manifold Mounting | Manifolds / Unit for Manifold Mounting | Single Use | Single Use / Unit for Manifold Mounting | Unit for Manifold Mounting | Unit for Manifold Mounting | Single Use | Single Use / Unit for Manifold Mounting | Single Use / Unit for Manifold Mounting | Single Use / Unit for Manifold Mounting | Single Use / Unit for Manifold Mounting | Single Use / Unit for Manifold Mounting | Single Use / Unit for Manifold Mounting | Single Use / Unit for Manifold Mounting | Single Use / Unit for Manifold Mounting | Single Use / Unit for Manifold Mounting | Single Use / Unit for Manifold Mounting | Single Use / Unit for Manifold Mounting | Single Use / Unit for Manifold Mounting | Single Use / Unit for Manifold Mounting | Unit for Manifold Mounting | Unit for Manifold Mounting | Unit for Manifold Mounting | Unit for Manifold Mounting | Unit for Manifold Mounting | Unit for Manifold Mounting | Unit for Manifold Mounting | Unit for Manifold Mounting | Unit for Manifold Mounting | Unit for Manifold Mounting | Unit for Manifold Mounting |

| Switching Type | 2-Position Normally Closed / 3-Position Closed Center | 2-Position Exhaust | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center / 3-Position Pressure Center / Others | 2-Position Exhaust / 3-Position Closed Center | Others | 2-Position Exhaust | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center / 3-Position Pressure Center | 2-Position Normally Open / 2-Position Normally Closed | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center / 3-Position Pressure Center / Others | 2-Position Exhaust / 3-Position Closed Center | 2-Position Exhaust | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center / 3-Position Pressure Center | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center / 3-Position Pressure Center | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center / 3-Position Pressure Center | 3-Position Closed Center | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center / 3-Position Pressure Center | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center / 3-Position Pressure Center | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center / 3-Position Pressure Center / Others | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center / 3-Position Pressure Center / Others | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center / 3-Position Pressure Center / Others | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center / 3-Position Pressure Center / Others | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center / 3-Position Pressure Center | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center / 3-Position Pressure Center | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center / 3-Position Pressure Center | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center / 3-Position Pressure Center | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center / 3-Position Pressure Center | 2-Position Exhaust | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center / 3-Position Pressure Center / Others | 2-Position Exhaust / 3-Position Closed Center / Others | 2-Position Normally Closed | 2-Position Exhaust / 3-Position Closed Center | 2-Position Exhaust / 3-Position Closed Center / 3-Position Exhaust Center |

| Voltage | DC12V / DC24V / AC100V / AC200V / AC220V | DC24V | DC12V / DC24V / AC100V / AC110V / AC200V / AC220V | DC24V | DC12V / DC24V | DC12V / DC24V | DC24V / AC100V / AC110V / AC200V / AC220V | DC12V / DC24V | DC24V | DC24V / AC100V / AC110V / AC200V / AC220V | DC24V | DC24V | DC24V | DC12V / DC24V / AC100V / DC5V | DC12V / DC24V / AC100V | DC24V / AC100V / AC200V | DC24V / AC100V / AC110V / AC200V / AC220V | DC24V | DC12V | DC24V / AC100V / AC200V / 110/120 V AC | DC24V / AC100V / AC200V / 110/120 V AC | DC24V / AC100V / AC200V / 110/120 V AC | DC24V / AC100V / AC220V / 110/120 V AC | DC24V / AC100V / 110/120 V AC | DC24V / AC100V / AC220V / 110/120 V AC | DC24V / AC100V / AC200V / 110/120 V AC | DC24V | DC24V | DC24V | DC12V / DC24V | DC24V | DC24V | DC12V / DC24V | DC24V | DC12V / DC24V / AC100V / AC200V / DC5V | DC12V / DC24V | DC24V |

| Number of Solenoids | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double | Double |

| Mounting Orientation | Direct | Manifold Base | Direct / Manifold Base | Manifold Base | Manifold Base | Manifold Base | Direct / Manifold Base | Manifold Base | Direct | Direct / Manifold Base | Manifold Base | Manifold Base | Direct | Direct / Manifold Base | Direct / Manifold Base | Direct / Manifold Base | Direct / Manifold Base | Direct / Manifold Base | Direct / Manifold Base | Direct / Manifold Base | Direct / Manifold Base | Direct / Manifold Base | Direct / Manifold Base | Direct / Manifold Base | Direct / Manifold Base | Direct / Manifold Base | Manifold Base | Manifold Base | Manifold Base | Manifold Base | Manifold Base | Manifold Base | Manifold Base | Manifold Base | Manifold Base | Manifold Base | Manifold Base |

| Pipe Port Type | Rc (R) / NPT / G | - | Rc (R) / NPT | One-Touch Plumbing | M | - | Rc (R) / NPT / NPTF | One-Touch Plumbing | Rc (R) / One-Touch Plumbing | Rc (R) | One-Touch Plumbing | One-Touch Plumbing | M / One-Touch Plumbing | M | M / Rc (R) / One-Touch Plumbing | Rc (R) / NPTF / G / One-Touch Plumbing | Rc (R) / NPT / G | Rc (R) / NPT / G | Rc (R) / NPT / G | Rc (R) / NPT / NPTF | Rc (R) / NPT / NPTF | Rc (R) / NPT / NPTF | Rc (R) / NPT / NPTF / G | Rc (R) / NPT / NPTF | Rc (R) / NPT / G | Rc (R) / NPT / G | - | - | - | - | - | - | One-Touch Plumbing / Barbed Couplers | One-Touch Plumbing | - | - | - |

| Specifications | Standard / Lubrication Free | Standard / Lubrication Free / No Copper, fluoropolymer Type Material / Low Current | Standard / High Frequency / Lubrication Free / Low Current | Lubrication Free / Low Current | Lubrication Free | Lubrication Free | Ozone Compatible / Lubrication Free | Standard | Lubrication Free | Drip-Proof / Lubrication Free | Lubrication Free | Lubrication Free | Lubrication Free | Lubrication Free / Cleanroom | Lubrication Free / Cleanroom | Lubrication Free / Cleanroom | Lubrication Free | Lubrication Free / Cleanroom | Lubrication Free | Lubrication Free | Lubrication Free | Lubrication Free | Lubrication Free | Lubrication Free | Lubrication Free | Lubrication Free | Drip-Proof / Lubrication Free | Drip-Proof / Lubrication Free | Drip-Proof / Lubrication Free | Standard / Lubrication Free | Lubrication Free / Cleanroom | Lubrication Free / Cleanroom | Lubrication Free | Standard | Lubrication Free | Standard | Drip-Proof / Lubrication Free |

| Status at Power Off | Self-Recovery (Spring Return) | Self-Retaining | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Recovery (Pressure Differential Return) | Self-Retaining | Self-Retaining / Self-Recovery (Spring Return) | Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) / Self-Recovery (Pressure Differential Return) | Self-Retaining / Self-Recovery (Spring Return) / Self-Recovery (Pressure Differential Return) | Self-Recovery (Pressure Differential Return) | Self-Retaining / Self-Recovery (Spring Return) | Self-Retaining / Self-Recovery (Spring Return) |

| Plumbing Thread Nominal | 1/2 ~ 3/8 | - | 1/4 ~ 1/8 | - | M5 | - | 1/4 ~ 3/8 | - | 1/8 | 1/4 ~ 3/8 | - | - | M5 | M3 ~ M5 | 1/8 ~ M5 | 1/4 ~ 1/8 | 1/2 ~ 3/8 | 1/2 ~ 3/8 | 1/2 ~ 3/8 | 1/4 ~ 1/8 | 1/4 ~ 3/8 | 1/2 ~ 3/8 | 1/2 ~ 3/8 | 1/4 ~ 1/8 | 1/4 ~ 3/8 | 1/2 ~ 3/8 | - | - | - | - | - | - | M5 | - | - | - | - |

| Plumbing | Direct Plumbing | Sub-Base Plumbing | Sub-Base Plumbing | Direct Plumbing | Direct Plumbing | Sub-Base Plumbing | Direct Plumbing / Sub-Base Plumbing | Direct Plumbing | Direct Plumbing | Sub-Base Plumbing | Direct Plumbing | Direct Plumbing | Direct Plumbing | Direct Plumbing / Sub-Base Plumbing | Direct Plumbing / Sub-Base Plumbing | Direct Plumbing / Sub-Base Plumbing | Sub-Base Plumbing | Sub-Base Plumbing | Sub-Base Plumbing | Sub-Base Plumbing | Sub-Base Plumbing | Sub-Base Plumbing | Sub-Base Plumbing | Sub-Base Plumbing | Sub-Base Plumbing | Sub-Base Plumbing | Sub-Base Plumbing | Sub-Base Plumbing | Sub-Base Plumbing | Sub-Base Plumbing | Sub-Base Plumbing | Sub-Base Plumbing | Direct Plumbing | Direct Plumbing | Sub-Base Plumbing | Sub-Base Plumbing | Sub-Base Plumbing |

| Applicable Cylinder Dia.(Ø) | 20 to 100 ~ 50 to 200 | - | 80 or Less | 40 or less | - | 50 or Less | - | - | - | - | 40 or less | 40 or less | 63 or less | - | - | - | 80 or Less ~ 125 or less | - | - | 20 to 40 ~ 40 to 160 | 40 to 140 ~ 40 to 200 | 50 to 300 ~ 80 to 300 | - | 20 to 100 ~ 40 to 160 | 40 to 140 ~ 40 to 200 | 50 to 300 ~ 80 to 300 | - | - | 200 or less | - | - | - | - | - | 20 or Less | 50 or Less | 100 or Less |

| Type | Solenoid Valves / Master Valve | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves | Solenoid Valves |

| Driving Type | Pilot Type Poppet / Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Poppet | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool | Pilot Type Spool |

| Connecting Tube Diameter | - | - | - | Ø4 / Ø6 | - | - | - | Ø4 / Ø1/8 / Ø5/32 / ø2 | Ø4 / Ø6 / Ø8 | - | Ø4 / Ø6 / Ø8 | Ø6 | Ø4 / Ø6 | - | Ø4 / Ø6 | Ø6 / Ø8 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | Ø4 / Ø6 | Ø4 / Ø6 | - | - | - |

| Pressure Rating(MPa) | 0.2 to 0.7 / -0.1 to 1 | 0.1 to 0.7 | 0.1 to 1.0 | 0.1 to 0.7 / 0.2 to 0.7 | -0.1 to 0.7 | 0.2 to 0.7 | 0.15 to 0.7 / 0.1 to 0.7 | 0 to 0.7 | 0.1 to 0.7 / 0.2 to 0.7 | 0.15 to 1 / 0.2 to 1 | 0.1 to 0.7 / 0.2 to 0.7 | 0.1 to 0.7 | 0.1 to 0.7 / 0.2 to 0.7 | 0.1 to 0.7 / 0.2 to 0.7 | 0.15 to 0.7 / 0.1 to 0.7 | 0.15 to 0.7 / 0.1 to 0.7 | 0.2 to 0.7 / -0.1 to 1 | 0.25 to 0.7 / 0.1 to 0.7 / 0.2 to 0.7 | 0.1 to 0.7 / 0.2 to 0.7 / -0.1 to 0.7 | 0.15 to 1 / 0.1 to 1.0 | 0.1 to 1.0 | 0.15 to 1 / 0.1 to 1.0 | 0.1 to 1.0 | 02 to 0.9 / 0.1 ~ 0.9 | 02 to 0.9 / 0.1 ~ 0.9 | 02 to 0.9 / 0.1 ~ 0.9 | 0.1 to 0.7 / 0.2 to 0.7 | 0.1 to 0.7 / 0.2 to 0.7 | 0.15 to 1 / 0.2 to 1 | 0.2 to 0.7 | 0.1 to 0.7 / 0.2 to 0.7 / 0.1 to 1.0 | 0.1 to 0.7 / 0.2 to 0.7 / 0.1 to 1.0 | 0.25 to 0.7 / 0.15 to 0.7 / 0.1 to 0.7 / 0.2 to 0.7 | - | 0.1 to 0.7 | 0.1 to 0.7 / 0.2 to 0.7 | 0.1 to 0.7 / 0.2 to 0.7 |

| Seal Type | Standard | Soft Seal | Standard | Soft Seal | Soft Seal | Soft Seal | Standard | Standard | Soft Seal | Soft Seal | Soft Seal | Soft Seal | Soft Seal | Soft Seal | Soft Seal | Soft Seal | Standard | Soft Seal | Soft Seal | Standard | Standard | Standard | Standard | Soft Seal | Soft Seal | Soft Seal | Standard / Soft Seal | Standard / Soft Seal | Standard / Soft Seal | Soft Seal | Standard / Soft Seal | Standard / Soft Seal | Standard | Standard | Soft Seal | Standard / Soft Seal | Standard / Soft Seal |

| CV Value | - | - | 0.56 ~ 0.6 | 0.15 ~ 0.19 | 0.05 | 0.11 | 0.17 ~ 1 | - | 0.19 ~ 0.49 | 1.9 ~ 2.1 | 0.46 ~ 0.51 | 0.51 | 0.23 ~ 0.26 | 0.1 ~ 0.12 | - | 0.34 ~ 0.78 | - | 0.24 ~ 2.2 | 0.44 ~ 2.2 | 0.53 ~ 0.63 | 1.4 ~ 1.8 | 2.5 ~ 2.9 | 3.7 ~ 4.6 | 0.24 ~ 0.62 | 1.7 ~ 2 | 3.2 ~ 4 | 0.16 ~ 0.21 | 0.46 ~ 0.8 | 1.5 ~ 2.1 | 0.11 | 0.16 ~ 0.21 | 0.46 ~ 0.55 | 0.14 ~ 0.18 | 0.14 ~ 0.18 | - | 0.16 ~ 0.21 | 0.46 ~ 0.55 |

| Pilot Air Supply | Internal / External | Internal | Internal / External | Internal | External | Internal / External | Internal | Internal | Internal | Internal / External | Internal | Internal | Internal | Internal | Internal | Internal | Internal / External | Internal / External | Internal / External | Internal | Internal | Internal / External | Internal / External | Internal | Internal / External | Internal / External | Internal / External | Internal / External | Internal / External | Internal | Internal | Internal | Internal / External | Internal / External | Internal | Internal | Internal |

Loading...

Configure

Specification/Dimensions

-

Number of Ports

-

Application

- Single Use

- Manifolds

- Unit for Manifold Mounting

-

Switching Type

-

Voltage

-

Number of Solenoids

- Single

- Double

-

Mounting Orientation

-

Pipe Port Type

-

Specifications

- Standard

- High Frequency

- Low Vacuum Compatible

- Explosion Proof

- Drip-Proof

- Ozone Compatible

- Lubrication Free

- No Copper, fluoropolymer Type Material

- Low Current

- Cleanroom

-

Status at Power Off

- Self-Retaining

- Self-Recovery (Spring Return)

- Self-Recovery (Pressure Differential Return)

-

Plumbing Thread Nominal

-

Plumbing

-

Applicable Cylinder Dia.(Ø)

-

Type

-

Driving Type

-

Connecting Tube Diameter

-

Pressure Rating(MPa)

-

Seal Type

-

CV Value

-

Pilot Air Supply

Narrow search by specifying Manufacturer

-

- SMC (123)

- CKD (17)

- CHELIC (12)

- KOGANEI (12)

- AIRTAC (6)

- NIHON SEIKI (1)

- KURODA PNEUMATICS (0)

- FESTO (0)

- SHIROKUMA (0)

- HINAKA (0)

- SHIMIZU (0)

- SHONANMARUHACHI (0)

CAD

-

- 2D

- 3D

How can we improve?

How can we improve?