(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla Firefox.

50,000 Stock items for Same Day Ship Out.

All Categories

Categories

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Application

Brands

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

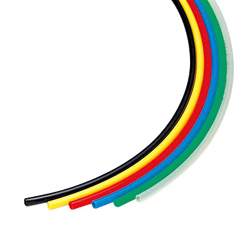

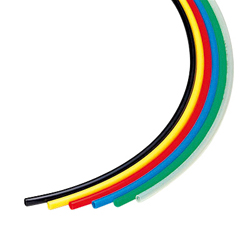

Air Tube/Nylon Tube(Material:Polyolefin Resin)

Additionally, we offer tubes capable of supporting various fluids such as water, chemicals, and general hydraulic oil. Complementary products like tube cutters and replacement blades are also available. For top-quality products, we highly recommend trusted brands such as MISUMI, SMC, PISCO, and CHIYODA.

Take advantage of the convenience of FREE SHIPPING and NO MINIMUM ORDER on Air tubes and related products. Should you have any doubts or require assistance in choosing the right product, our experts are readily available to provide advice and guidance.

| Days to Ship |

|

|---|

-

- On Sale Till 31/03/2025

SMC

Nylon tubing for general pneumatic tubing.

[Features]

・ Maximum operating pressure of 3.0 MPa or less (T0604, at 20°C)

[Applications]

・ Applicable fluids: Air, waterSpecial Price Days to Ship: Same day or more -

- On Sale Till 31/03/2025

Soft Nylon Tubing TS/TISA Series

SMC

Pliable soft nylon tubing.

[Features]

・ Maximum operating pressure of 1.0 MPa or less (At 20°C)

[Applications]

・ For general pneumatic piping- Volume Discount

Special Price Days to Ship: Same day or more -

- On Sale Till 31/03/2025

SMC

Tubing to which measures against static electricity have been applied.

[Features]

· Maximum operating pressure 1.2 MPa or less (at 20°C).

· For pneumatic piping and applications which require measures against static electricity.

· Flame-retardant tubing (equivalent to UL-94 standard V-0).

· Fluid: air.

· Color: black.

[Applications]

· For preventing static electricity.Standard Price: SGD 47.72- Special Price Days to Ship: 32 Day(s) -

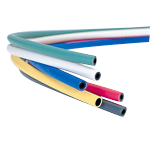

Clean Tubing: Soft Polyolefin Tubing TPS Series

SMC

Clean tubing: soft polyolefin tubing in a variety of colors.

[Features]

· Maximum operating pressure 0.7 MPa (at 20°C).

· RoHS compliant.

[Applications]

· Fluid: Air, nitrogen gas, water, DI water (pure water).Days to Ship: 32 Day(s) or more -

Flame Retardant (Equivalent To UL-94 Standard V-0) FR Soft Nylon Tubing TRS Series

SMC

Flame-retardant tubing.

[Features]

· Maximum operating pressure 1.2 MPa or less (at 20°C)

· For use in environments where spatter may occur / Flame retardant (equivalent to UL-94 standard V-0)

[Applications]

· Suitable for air and water piping in environments with sparks from spot welders, etc.Days to Ship: 32 Day(s) or more -

L-Flex Polyurethane Tube for Spattering Prevention

CHIYODA

Air piping tube suitable for welding environment.

[Features]

・ Anti-spatter tube coated with polyolefin resin

・ Very small bend radius and easy to handle

・ A tube with spatter resistance that can be used with both air and cooling water

・ Inner TE tube. Inheriting the same features as TP tubes. Can be used without distinction between cooling water (industrial water) and air at welding points

・ Wide color variations. Convenient for pipe management

・ 2-layer structure. Improved spatter resistance by separating the inner tube (TE) and outer skin (flame retardant)

[Applications]

・ Ideal for welding parts air piping (welding jigs, welding robots, welding machines, etc.)

・ Convenient for cutting chips (around lathe, etc.)Standard Price: SGD 109.22- Days to Ship: 4 Day(s) or more -

ALE Type L-Flex Spatter-Resistant Tube

CHIYODA

[Features]

· Inner TE tube. The features of TP tubes are all inherited. At welding sites, the tube can be used for both air and cooling water (industrial water) without separation

・ Wide color variations. Convenient for pipe management

・ 3-layer tube. The LE inner is coated with an aluminum film to further improve spatter resistance and the strongest specification for sputter tubesStandard Price: SGD 186.03- Days to Ship: 4 Day(s) or more -

Polyolefin Resin Tube Clean Pipes (Flexible) PL

NITTA

[Features]

・ A clean tube that uses clean air, N2 gas, pure water, or various chemicals,etc., as a fluid, and is suitable for installation and applications.

・ Environmentally friendly eco-type tube. Carbon dioxide is the only gas generated during incineration (750°C), and no toxic gases such as nitrogen oxides (NOx) and sulfur oxides (SOx) are generated. No dioxin is generated

・ Manufactured in a cleanroom, the tube terminal is sealed with a cap, and shipped in heat-sealed packaging

・ Uses a special polyolefin resin with excellent moisture barrier properties and flexibility

・ Economical compared to fluoropolymer tubes

・ Compliant with Ministry of Health, Labour and Welfare of Japan Notification No. 201 (2006) and Ministry of Health, Labour and Welfare Notification No. 370 (1959)Standard Price: SGD 10.66- Days to Ship: 4 Day(s) or more -

Polyolefin Resin Tube Clean Pipes (Ultra-Flexible) PN

NITTA

[Features]

・ A clean tube that uses clean air, N2 gas, pure water, or various chemicals,etc., as a fluid, and is suitable for installation and applications.

・ Environmentally friendly eco-type tube

・ Carbon dioxide is the only gas generated during incineration (750°C), and no toxic gases such as nitrogen oxides (NOx) and sulfur oxides (SOx) are generated

・ No dioxin is generated

・ Manufactured in a cleanroom, the tube terminal is sealed with a cap, and shipped in heat-sealed packaging

・ Uses a special polyolefin resin that has excellent moisture barrier properties and is even more flexible than PL tubes

・ Economical compared to fluoropolymer tubes

・ Compliant with Ministry of Health, Labour and Welfare of Japan Notification No. 201 (2006) and Ministry of Health, Labour and Welfare Notification No. 370 (1959)Standard Price: SGD 31.27- Days to Ship: 4 Day(s) or more -

Clean Tubing, Polyolefin Tubing, TPH Series (20 m / 100 m)

SMC

A RoHS-compliant clean tube.

[Features]

· Applicable fittings: clean one-touch fitting, metal one-touch fitting KQB2 Series.

· Applicable fittings: SUS316 one-touch fittings KQG2 series, insert fittings.

· Colors: white (material color) / black (opaque) / red (opaque) / blue (opaque) / yellow (opaque) / green (opaque).

· Length: 20 m roll / 100 m roll.Days to Ship: 32 Day(s) or more -

MISUMI

[Features]·Tube suitable for applications in fields such as food and beverage industries, physical and chemical sciences, etc.

- Volume Discount

Days to Ship: 4 Day(s) or more -

Slim L-Flex Sputter Preventing Polyurethane Tube

CHIYODA

Tube with flexibility in addition to sputtering resistance.

[Features]

· Achieves both sputtering resistance and flexibility. By thinning the outer skin of a conventional L-Flex tube, sputtering resistance is improved and excellent flexibility is provided.

· Lightweight 25% lighter weight compared to conventional L-Flex tubing.

· Excellent outer skin peeling properties. The outer skin is easier to peel and construction is easier than with conventional two-layer tubingStandard Price: SGD 69.42- Days to Ship: 9 Day(s) or more -

Twin L-Flex Sputter Preventing Polyurethane Tube

CHIYODA

[Features]

· Directly inherits the features of the TE tube.

· A sputter-preventing tube optimal for in-out pipingStandard Price: SGD 261.40- Days to Ship: 13 Day(s) or more

| Brand |

|---|

| Product Series |

| CAD |

| Days to Ship |

| Outer Dia. D(Ø) |

| Inner Dia. d(Ø) |

| Material |

| Applicable Fluid |

| Color |

| Type |

| Operating Environment |

| O.D. [Distinction] |

| Cutting Service Usage |

| Material: Nylon |

| I.D. [Distinction] |

| Material, Fluororesin |

| Material, Urethane |

| Number of Core(Core) |

| O.D. (2nd Core) |

| O.D. (3rd Core) |

| O.D. (4th Core) |

| O.D. (5th Core) |

| I.D. (2nd Core) |

| I.D. (3rd Core) |

| I.D. (4th Core) |

| I.D. (5th Core) |

| Types of Related components |

|

|

| |||||||||||

| Brand | SMC | SMC | SMC | SMC | SMC | CHIYODA | CHIYODA | NITTA | NITTA | SMC | MISUMI | CHIYODA | CHIYODA |

| Product Series | Flame Retardant (Equivalent To UL-94 Standard V-0) FR Soft Nylon Tubing TRS Series | ||||||||||||

| CAD |

| ||||||||||||

| Days to Ship | Same day or more | Same day or more | 32 Day(s) | 32 Day(s) or more | 32 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 32 Day(s) or more | 4 Day(s) or more | 9 Day(s) or more | 13 Day(s) or more |

| Outer Dia. D(Ø) | 3.18 ~ 16 | 3.18 ~ 16 | 4 ~ 12 | 4 ~ 12 | 6 ~ 12 | 8 ~ 14 | 8.2 ~ 14.2 | 4 ~ 12.7 | 3 ~ 12 | 4 ~ 12 | 4 ~ 12 | 7 ~ 13 | 8 ~ 14 |

| Inner Dia. d(Ø) | 2.5 ~ 13 | 2.5 ~ 12 | 2.5 ~ 8 | 2.5 ~ 8 | 3 ~ 8 | 4 ~ 8 | 4 ~ 8 | 2 ~ 9.56 | 2 ~ 8 | 2.5 ~ 9 | 2.5 ~ 8 | 4 ~ 8 | 4 ~ 8 |

| Material | Polyolefin Resin | Polyolefin Resin | Polyolefin Resin | Polyolefin Resin | Polyolefin Resin | Polyolefin Resin | Polyolefin Resin | Polyolefin Resin | Polyolefin Resin | Polyolefin Resin | Polyolefin Resin | Polyolefin Resin | Polyolefin Resin |

| Applicable Fluid | Water / Air | Water / Air | Air | Water / Air | Water / Air | Water / Air | Water / Air | Water / Air | Water / Air | Water / Air | - | Water / Air | Water / Air |

| Color | Black / White / Red / Blue / Yellow / Green | Black / White / Red / Blue / Yellow / Green | Black | Black / White / Red / Blue / Yellow / Green | Black / White / Red / Blue / Green | Black / White / Red / Blue / Yellow / Green | Black / White / Red / Blue / Yellow / Green | Black / Milky White / Red / Blue / Yellow / Green | Milky White / Transparent (including non-white colors) | Black / White / Red / Blue / Yellow / Green | White | Black / White / Red / Blue / Yellow / Green | Black / White / Red / Yellow / Green |

| Type | Straight | Straight | Straight | Straight | Straight | Straight | Straight | Straight | Straight | Straight | Straight | Straight | Straight |

| Operating Environment | Standard | Standard | Standard | Standard | Standard | Standard / Sputtering Resistant / Water Resistance / Vacuum / Heat Resistance / Oil Resistance | Standard / Sputtering Resistant / Water Resistance / Vacuum / Heat Resistance / Oil Resistance | Standard | Standard | Standard / Clean Environment | - | Standard / Sputtering Resistant / Water Resistance / Vacuum / Heat Resistance / Oil Resistance | Standard / Sputtering Resistant / Water Resistance / Vacuum / Heat Resistance / Oil Resistance |

| O.D. [Distinction] | ~4 ~ ~20 | ~4 ~ ~20 | ~4 ~ ~15 | ~4 ~ ~15 | ~6 ~ ~15 | ~8 ~ ~15 | ~9 ~ ~15 | ~4 ~ ~15 | ~3 ~ ~15 | ~4 ~ ~15 | - | ~7 ~ ~15 | ~8 ~ ~15 |

| Cutting Service Usage | No | No | No | No | No | No | No | Yes / No | No | Yes | Yes | No | No |

| Material: Nylon | Nylon 12 | Nylon 12 | Others | - | Others | - | - | - | - | - | - | - | - |

| I.D. [Distinction] | ~3 ~ ~15 | ~3 ~ ~15 | ~3 ~ ~8 | ~3 ~ ~8 | ~3 ~ ~8 | ~4 ~ ~8 | ~4 ~ ~8 | ~2 ~ ~10 | ~2 ~ ~8 | ~3 ~ ~9 | - | ~4 ~ ~8 | ~4 ~ ~8 |

| Material, Fluororesin | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Material, Urethane | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Number of Core(Core) | - | - | - | - | - | - | - | - | - | 1 | - | - | - |

| O.D. (2nd Core) | - | - | - | - | - | - | - | - | - | - | - | - | - |

| O.D. (3rd Core) | - | - | - | - | - | - | - | - | - | - | - | - | - |

| O.D. (4th Core) | - | - | - | - | - | - | - | - | - | - | - | - | - |

| O.D. (5th Core) | - | - | - | - | - | - | - | - | - | - | - | - | - |

| I.D. (2nd Core) | - | - | - | - | - | - | - | - | - | - | - | - | - |

| I.D. (3rd Core) | - | - | - | - | - | - | - | - | - | - | - | - | - |

| I.D. (4th Core) | - | - | - | - | - | - | - | - | - | - | - | - | - |

| I.D. (5th Core) | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Types of Related components | - | - | - | - | - | - | - | - | - | - | - | - | - |

Loading...

Configure

Specification/Dimensions

-

Outer Dia. D(Ø)

-

Inner Dia. d(Ø)

- 0.7

- 0.8

- 0.9

- 1

- 1.2

- 1.5

- 1.58

- 1.59

- 1.6

- 2

- 2.1

- 2.25

- 2.3

- 2.36

- 2.42

- 2.5

- 2.6

- 2.7

- 2.9

- 2.99

- 3

- 3.17

- 3.21

- 3.48

- 3.5

- 3.7

- 3.8

- 3.95

- 3.96

- 4

- 4.02

- 4.15

- 4.35

- 4.5

- 4.57

- 4.76

- 4.81

- 5

- 5.5

- 5.7

- 5.9

- 5.99

- 6

- 6.2

- 6.3

- 6.33

- 6.35

- 6.4

- 6.5

- 6.8

- 6.99

- 7

- 7.5

- 7.6

- 8

- 8.3

- 8.4

- 8.5

- 9

- 9.5

- 9.52

- 9.56

- 9.8

- 10

- 10.7

- 11

- 12

- 12.5

- 12.7

- 12.8

- 13

- 14

- 15.88

- 16

- 22

- 22.2

- 23

-

Material

- Urethane

- Nylon

- Fluororesin

- Polyamide

- Fluororubber

- Silicon Rubber

- Polyolefin Resin

- Others

- PVC

- Nylon/Fluoropolymer

-

Applicable Fluid

- Water

- Air

- Chemical

- General Hydraulic Oil

- Thermal Media Oil

- Vacuum

-

Color

- Black

- White

- Milky White

- Transparent (including non-white colors)

- Red

- Blue

- Yellow

- Green

- Orange

- Ocher

- Gray

- Multi Color

- Pink

- Others

- Brown

- Purple

- Silver

-

Type

-

Operating Environment

- Standard

- Clean Environment

- Corrosion Resistant

- Antistatic

- Sputtering Resistant

- Mold Cooling

- Water Resistance

- Pressure Resistance

- Vacuum

- Heat Resistance

- Abrasion Resistance

- Oil Resistance

- low temperature resistance

- Weather Resistance

- Chemical Resistance

-

O.D. [Distinction]

-

Cutting Service Usage

- Yes

- No

-

Material: Nylon

-

I.D. [Distinction]

-

Material, Fluororesin

-

Material, Urethane

-

Number of Core(Core)

-

O.D. (2nd Core)

-

O.D. (3rd Core)

-

O.D. (4th Core)

-

O.D. (5th Core)

-

I.D. (2nd Core)

-

I.D. (3rd Core)

-

I.D. (4th Core)

-

I.D. (5th Core)

-

Types of Related components

Narrow search by specifying Manufacturer

-

- SMC (6)

- CHIYODA (4)

- NITTA (2)

- MUROMOTO TEKKO (0)

- GUNZE (0)

- MIRUC OPTICAL (0)

- IFIELD (0)

- KOGANEI (0)

- TAIYO (0)

- JUNKOSHA (0)

- PISCO (0)

- AIRTAC (0)

- YODOGAWA (0)

- CHUKOH (0)

- AOI (0)

- TRUSCO NAKAYAMA (0)

- NICHIAS (0)

- IWATA MFG (0)

- EASUN (0)

- ESCO (0)

- CHELIC (0)

- CKD (0)

- FESTO (0)

CAD

-

- 2D

- 3D

Related Categories to Air Tube/Nylon Tube

-

- Cylinders, Rotary Actuators

- Cylinder Connecting Components

- Filters, Regulators, Lubricators

- Solenoid Valves

- Electromagnetic Valves

- Pneumatic Pipe Fittings

- Speed Controllers

- Silencers

- Manual-Type Valves, Mechanical-Type Valves

- Air Tube/Nylon Tube

- Fluororesin Products for Chemicals

- Pressure, Flow Rate Sensors

- Dryers

- Compressors, Blowers

- Other Pneumatic Devices

-

How can we improve?

How can we improve?